Three-dimensional printing device and printing platform system thereof

A printing platform and three-dimensional printing technology, which is applied in the direction of manufacturing auxiliary devices, processing drive devices, processing platforms/substrates, etc., can solve problems such as inability to change, design model errors, and difficulty in significantly improving the accuracy of three-dimensional printing of curved parts, achieving reduction The effect of printing volume and improving print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0031] Embodiment of three-dimensional printing device

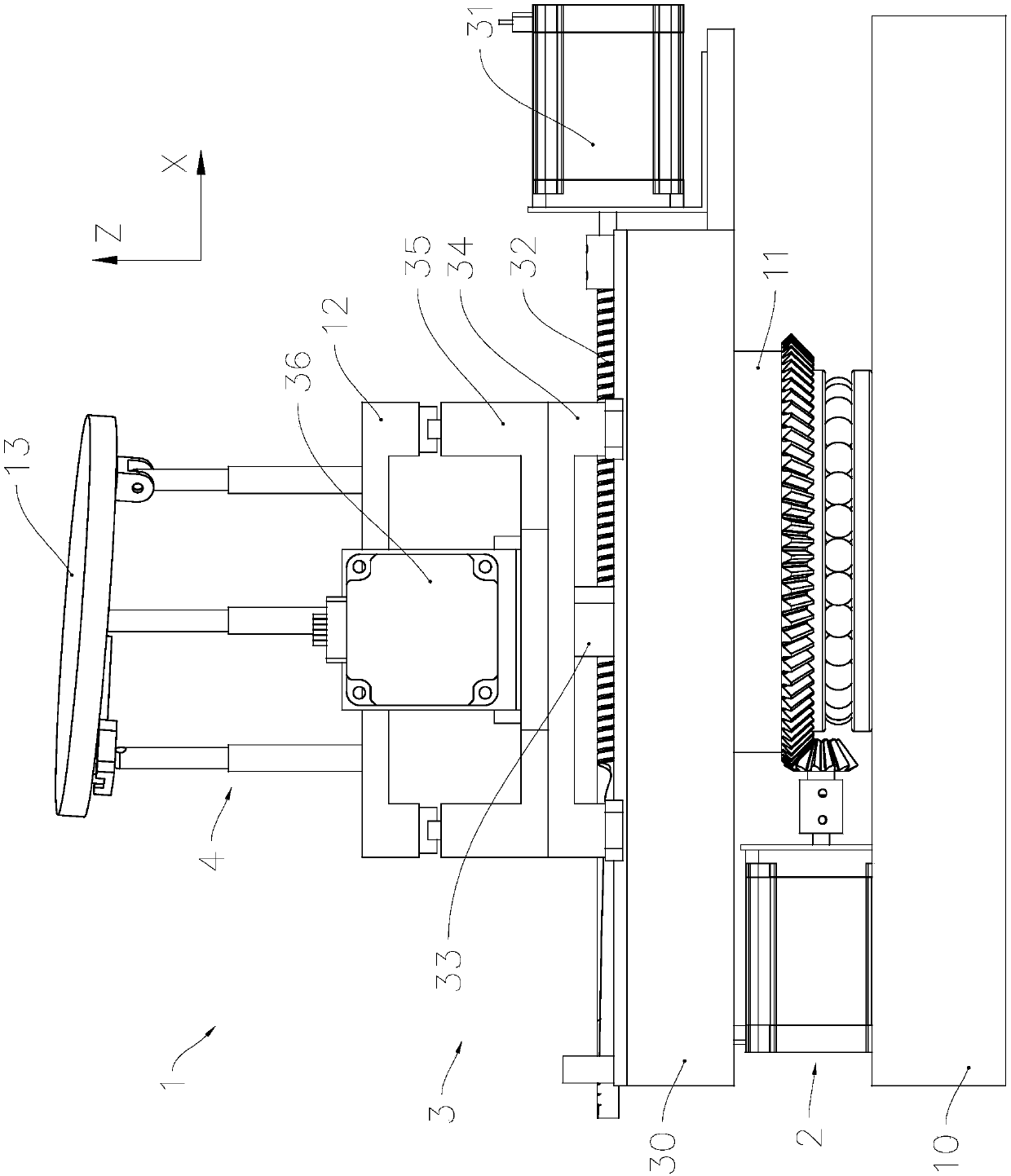

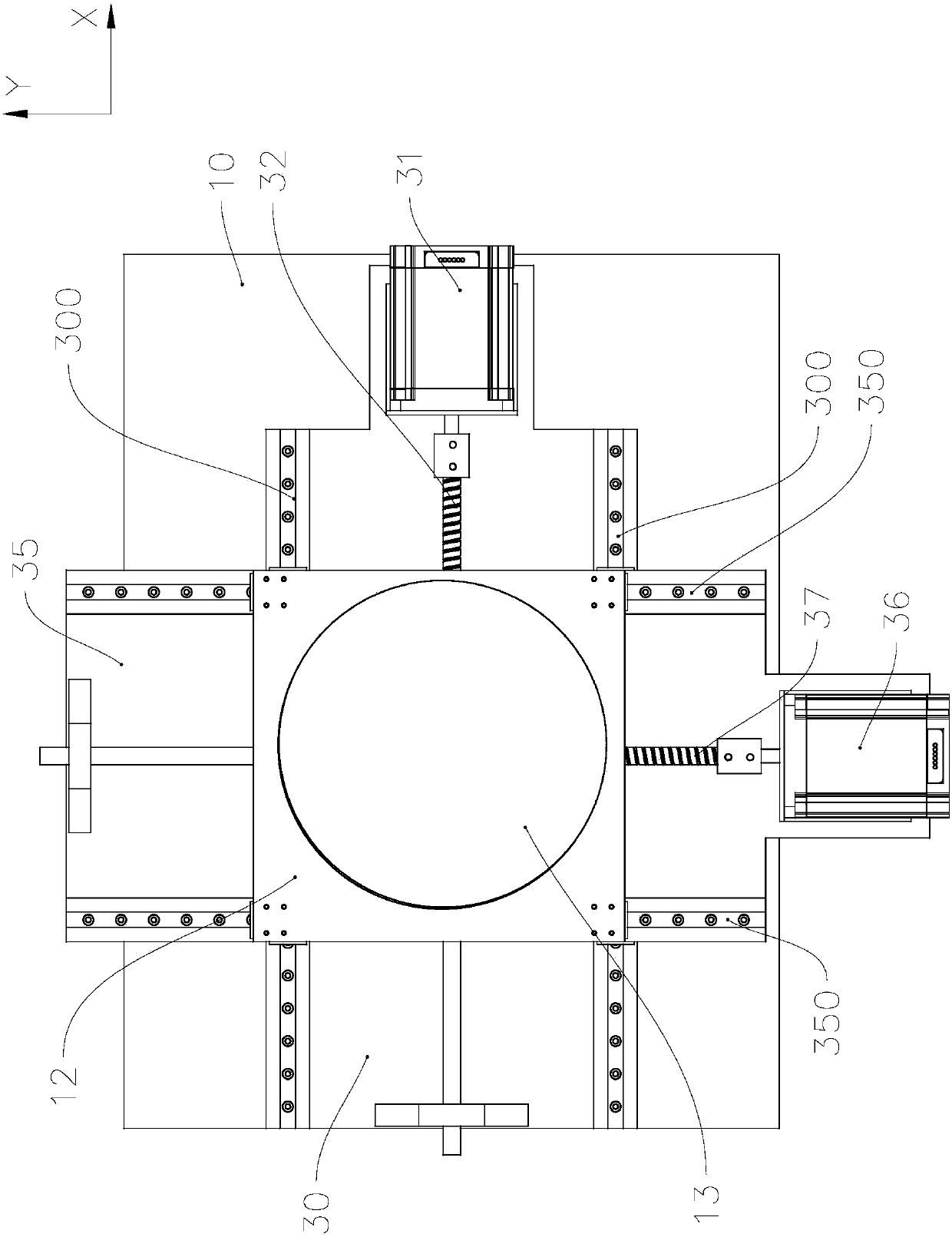

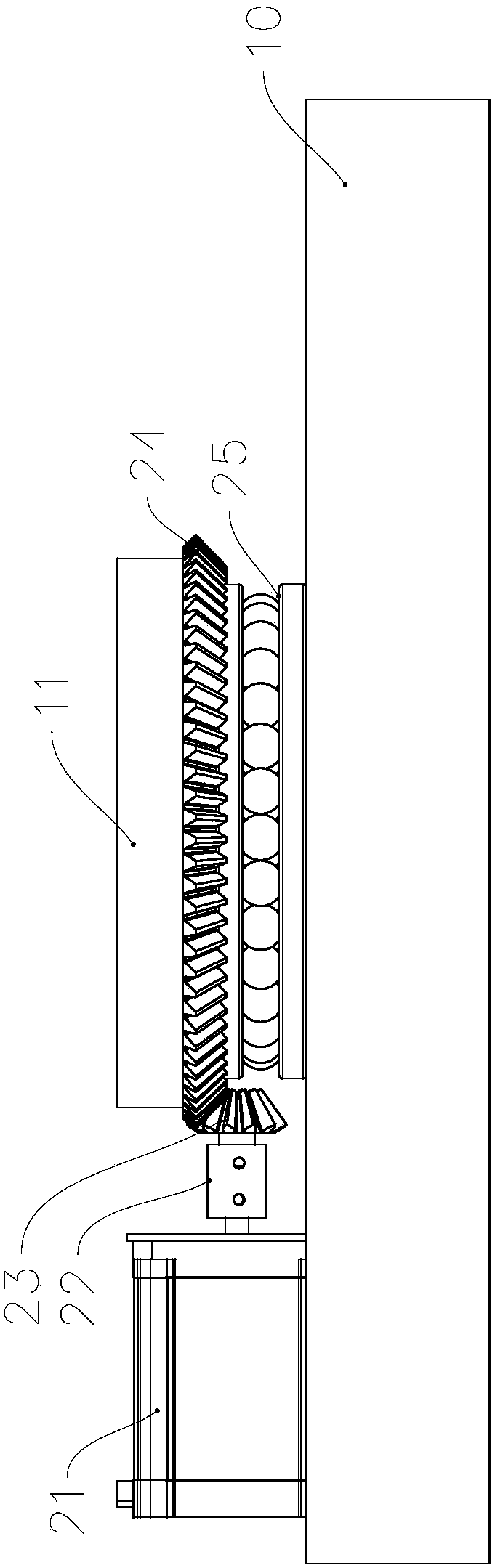

[0032] see Figure 1 to Figure 4 , the three-dimensional printing device of the present invention includes a control unit, a frame, and a printing head and a printing platform system 1 installed on the frame and controlled by the control unit.

[0033] The printing platform system 1 includes a mounting base 10, a driving system and a printing platform 13. The driving system includes a turntable 11 that is rotatably mounted on the mounting base 10 through a rotating shaft, and a rotary driver 2 that drives the rotating table 11 to rotate around the rotating shaft. The slide table 12 installed on the turntable 11, and the transverse driver 3 that drives the slide table to move in two dimensions on the X-Y plane. In this embodiment, the X-Y plane is arranged along the transverse direction, the X axis con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com