Digital inkjet printing device of conventional flat screen printing machine

A flat screen printing and digital inkjet technology, applied in the field of digital inkjet printing devices, can solve the problems of printing slurry waste, sewage discharge, etc., and achieve the effect of improving printing quality and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Now in conjunction with accompanying drawing, the present invention will be further described:

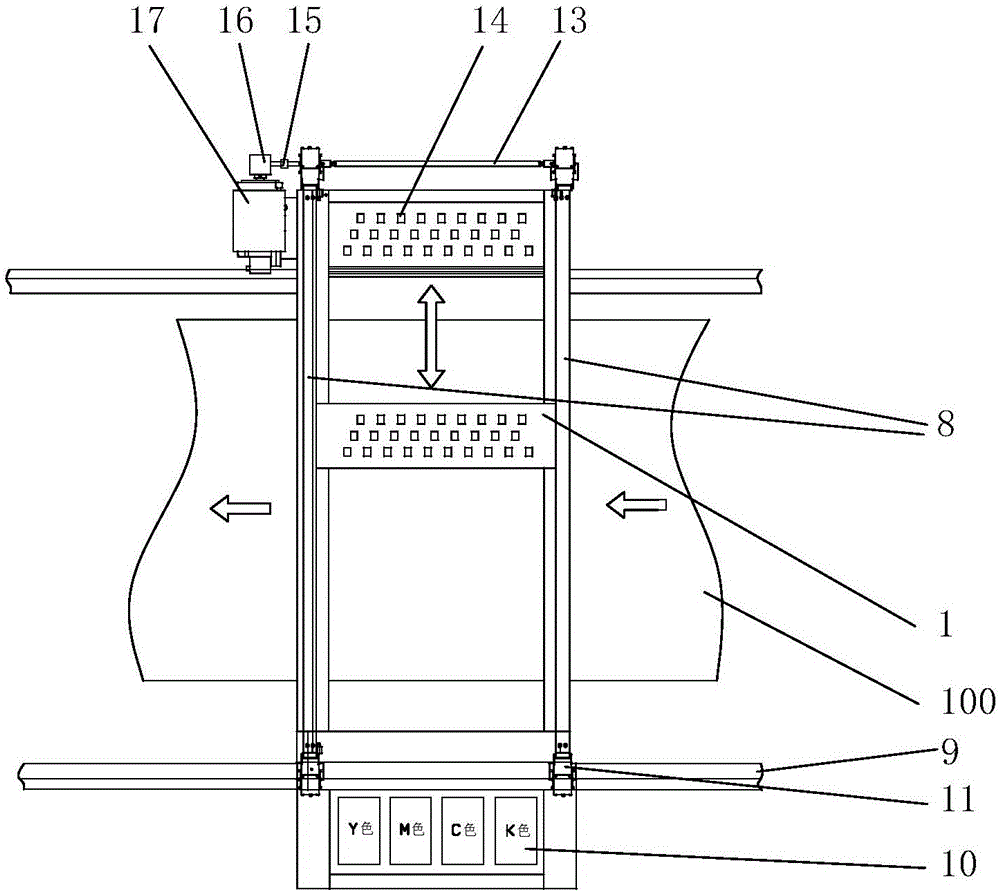

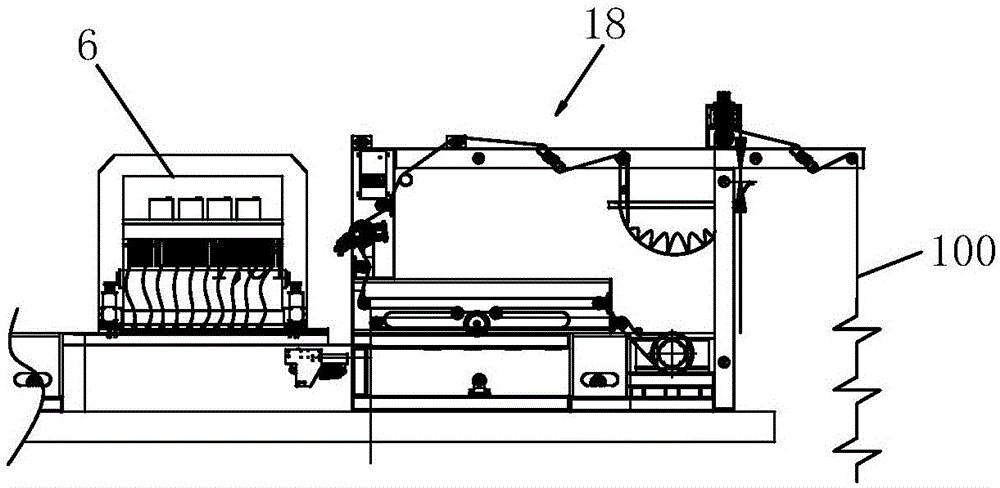

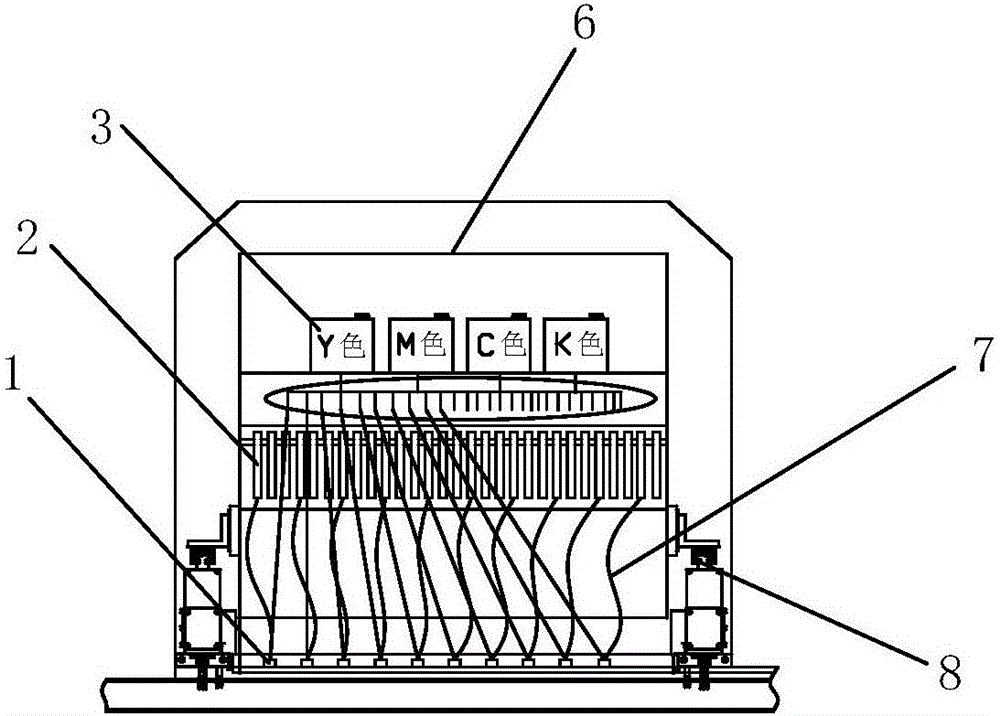

[0052] As shown in the figure, a digital inkjet printing device of a traditional flat screen printing machine includes:

[0053] frame;

[0054] The cloth feeding device 18 is installed on the frame;

[0055] It is characterized in that it also includes:

[0056] The printing guide belt 102 is installed on two transmission wheels 103, and the gray cloth 100 falls to the input end of the printing guide belt 102, the output end of the printing guide belt 102, the drying device to the winding system through the cloth feeding device 18;

[0057] The guide belt servo motor 101 is linked with one of the drive wheels 103, and the guide belt servo motor 101 is connected to the controller;

[0058] Scanning type integrated mobile car motion slide bar 8, two, fixed on the frame according to the direction of gray cloth 100 width;

[0059] The scanning integrated transfer vehicle 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com