Treatment method of wood processing residues and charcoal prepared thereby

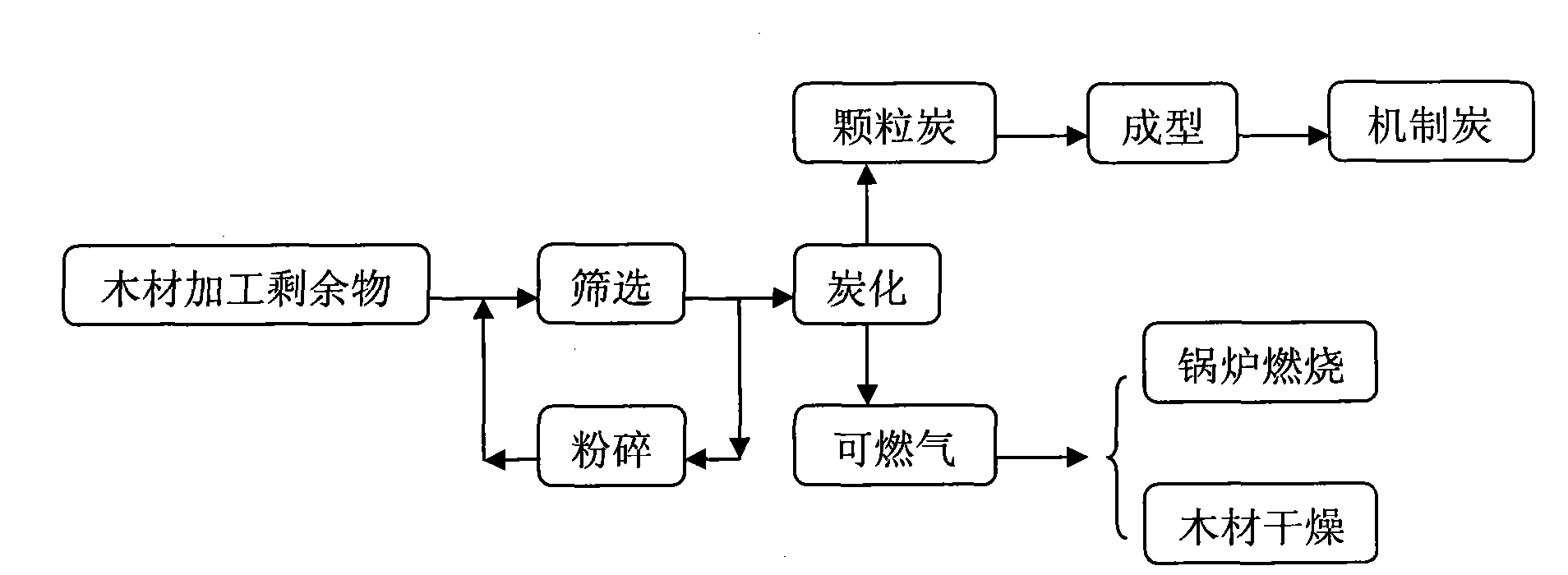

A technology for processing residues and treatment methods, which is applied in the field of dry distillation of charcoal, gas products, and wood processing residues. It can solve problems such as limited use occasions, scattered layout, and incomplete carbonization, so as to improve energy utilization and produce Ease of use and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The coniferous wood shavings left over from wood processing are used as raw materials, wherein the particle size of the coniferous shavings: 10-40mm; moisture content: 10-16%.

[0046] 1) Crushing and screening of raw materials

[0047] Screen coniferous wood shavings, and send particles with an equivalent volume diameter ≤ 30mm directly into the carbonization furnace; for particles with an equivalent volume diameter greater than 30mm, they are pulverized by a pulverizer to make their equivalent volume diameter ≤ 30mm and then sent to the carbonization furnace , wherein the weight of particles with an equivalent volume diameter < 5 mm accounts for 20% of the total weight of the remainder; the weight of particles with an equivalent volume diameter within the range of 5-20 mm accounts for 50% of the total weight of the remainder;

[0048] 2) Carbonization

[0049] Heat the carbonization furnace to increase the temperature in the carbonization furnace to 500°C, and keep t...

Embodiment 2

[0058] In addition to the weight of particles with an equivalent volume diameter of 3 / kg (wood), that is, every 1kg of wood passes through 2.0m 3 air, the carbonization time is 2h; the weight ratio of solid particles and sodium phosphate in the mechanism carbon preparation process is 75:25, the rest is the same as that of Example 1.

[0059] The performance index of the prepared formed carbon was tested according to the national standard GB / T17664-1999, and the test results are shown in Table 1.

Embodiment 3

[0061] In addition to the weight of particles with an equivalent volume diameter of 3 / kg (wood), that is, every 1kg of wood passes through 3.5m 3 air, and the carbonization time was 2 hours; the weight ratio of solid particles and potassium sulfate in the process of machine-made carbon preparation was 95:5, and the rest were the same as in Example 1.

[0062] The performance index of the prepared formed carbon was tested according to the national standard GB / T17664-1999, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com