Deacidifying agent based on alkyl ketene dimer modified nano-magnesia and preparation method of deacidifying agent

A technology of alkyl ketene dimer and nano-magnesium oxide, which is applied in the post-treatment of waste paper, etc., can solve the problems of poor dispersion and achieve the effects of mild reaction conditions, cost reduction and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

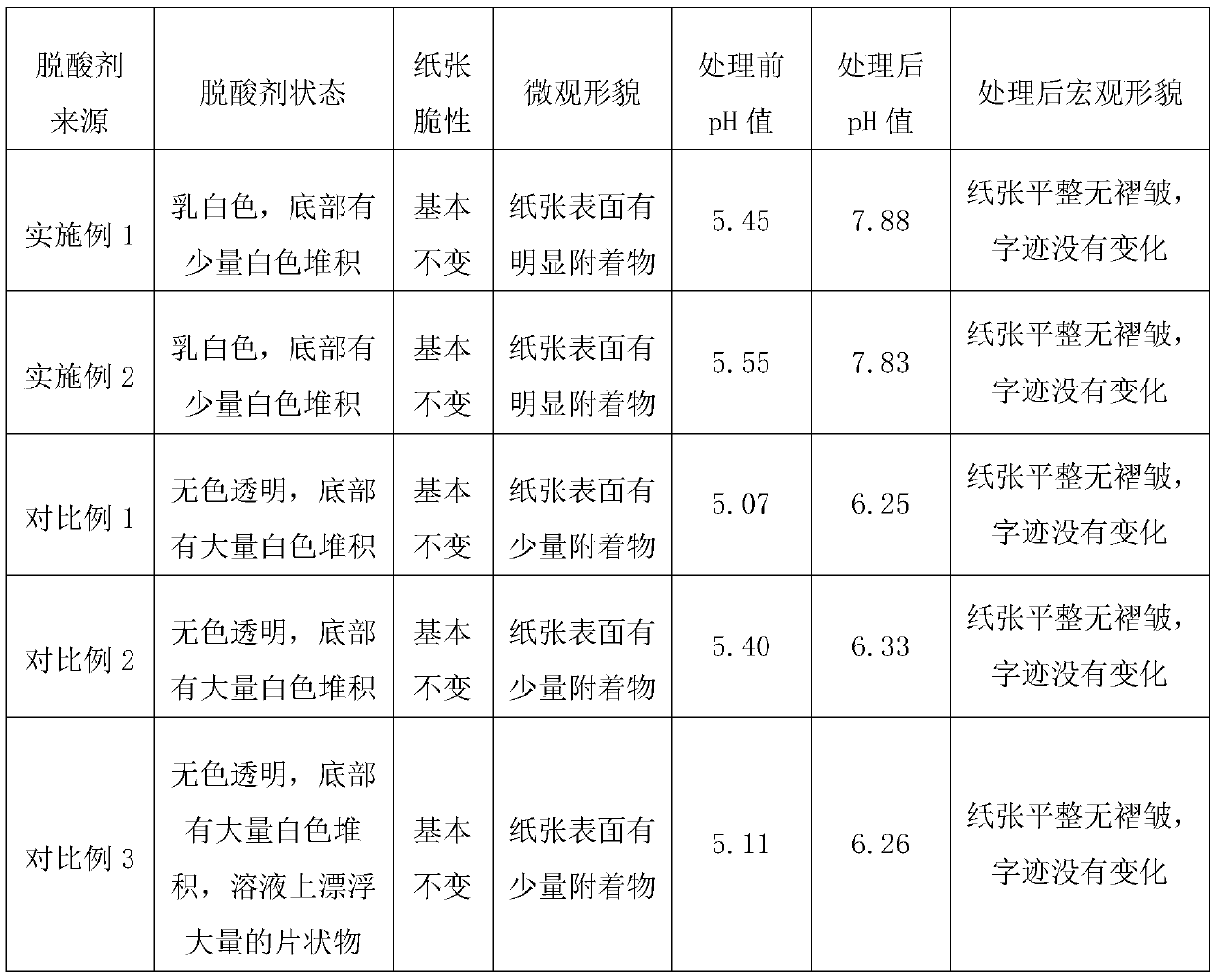

Examples

Embodiment 1

[0022] Heat 2g of alkyl ketene dimer to 110°C to melt completely, then add 1.5g of nano-magnesium oxide and stir at this temperature for 30min. After the reaction is completed, filter with suction, wash the filter cake repeatedly with a total of about 100 mL of hot ethanol at a temperature of 75°C, and finally dry the filter cake in a vacuum at 35°C for 24 hours to obtain modified nano-magnesium oxide.

[0023] 800g of perfluoroheptane and 16g of petroleum ether were mixed and stirred uniformly to obtain a mixed solvent. Add 1.5g of dried modified nano-magnesium oxide into the mixed solvent, transfer the obtained mixture to a homogenizer, homogenize it for 8 minutes under the condition of 8000r / min, and then sonicate it for 30 minutes, which is the deacidification agent.

Embodiment 2

[0025] Heat 2.5g of alkyl ketene dimer to 110°C to make it melt completely, then add 2.5g of nano-magnesium oxide and stir at this temperature for 30min. After the reaction is completed, filter with suction, wash the filter cake repeatedly with a total of about 120 mL of hot ethanol at a temperature of 75°C, and finally dry the filter cake in a vacuum at 35°C for 24 hours to obtain modified nano-magnesium oxide.

[0026] 1615g of perfluoroheptane and 35g of petroleum ether were mixed and stirred uniformly to obtain a mixed solvent. Add 2.5g of dried modified nano magnesium oxide into the mixed solvent, transfer the resulting mixture to a homogenizer, homogenize it at 8000r / min for 8min, and then sonicate it for 30min to obtain a deacidifying agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com