Wood finger joint system and method

A wood and joint technology, applied in the field of wood processing, can solve problems such as poor flatness and inability to ensure the consistency of tooth shape, and achieve the effects of good consistency, improved efficiency and reduced machining allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

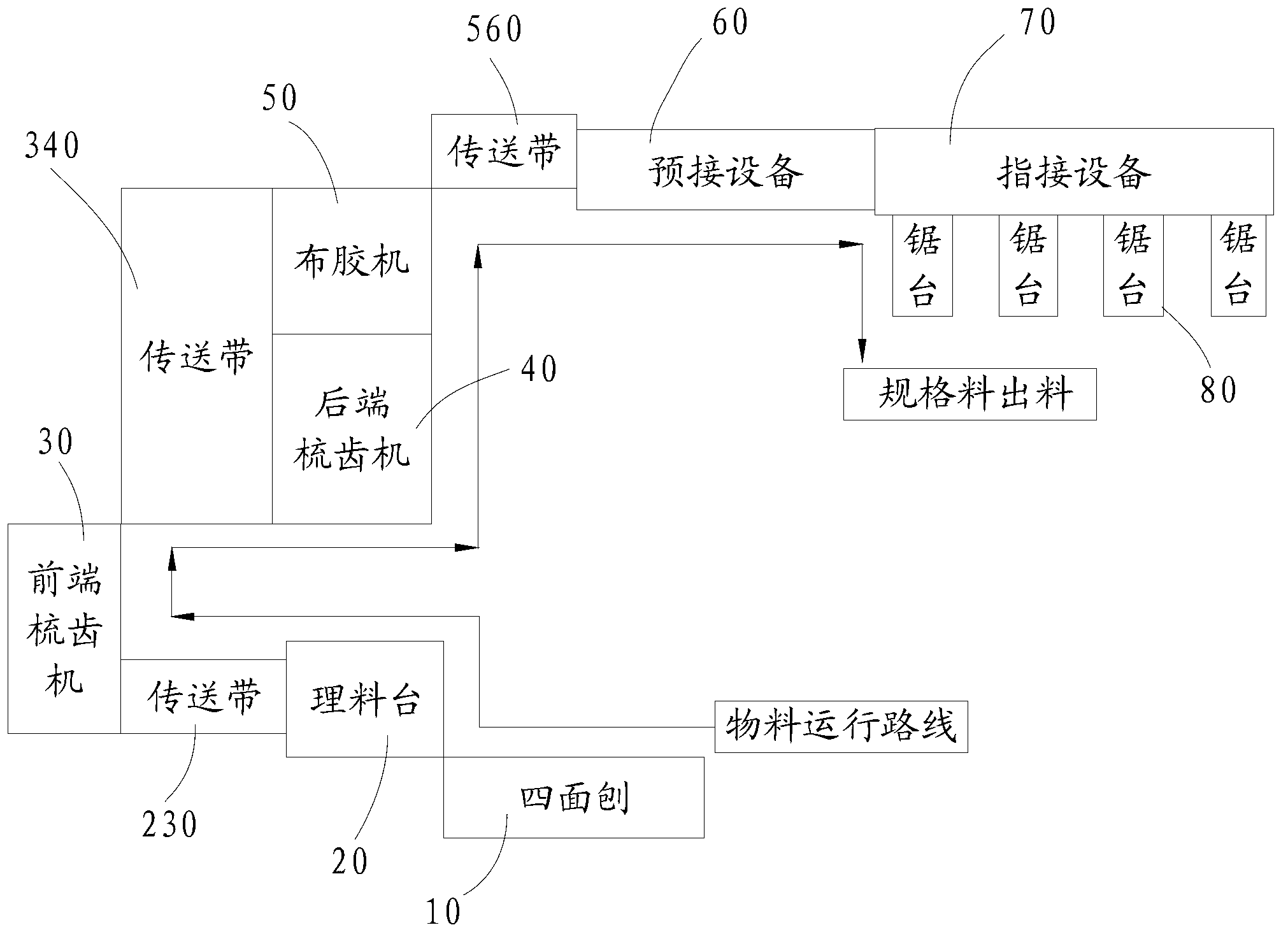

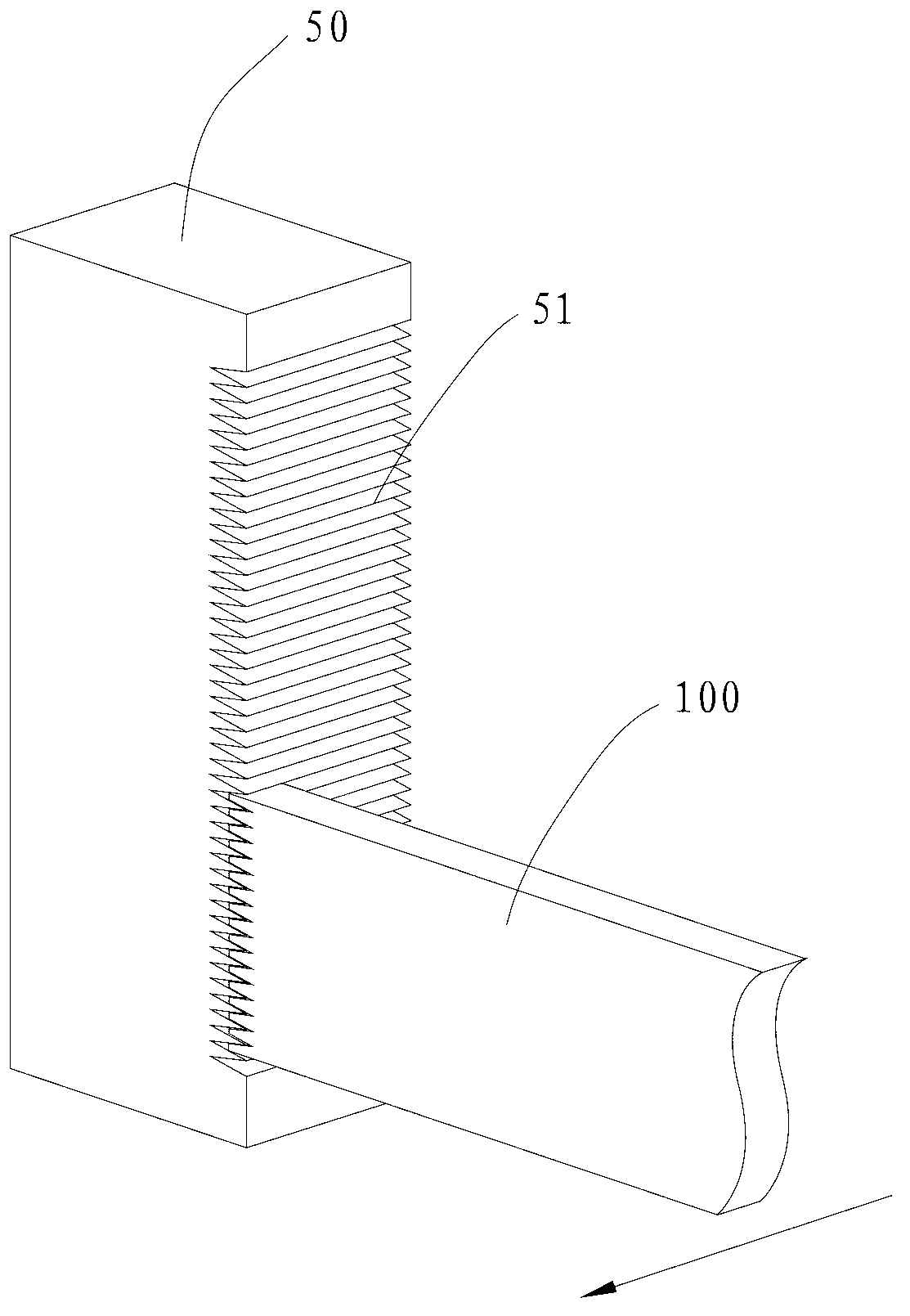

[0025] see figure 1 as well as figure 2 , the present embodiment provides a wood finger-joining system, including a four-sided planer 10, a sorting table 20, a front-end comb machine 30, a rear-end comb machine 40, a gluing machine 50, a pre-joining device 60 and Finger-joint equipment 70; a conveyor belt 230 is arranged between the sorting table 20 and the front-end comb machine 30, a conveyor belt 340 is arranged between the front-end comb machine 30 and the rear-end comb machine 40, and the glue machine 50 and the rear-end comb The machine 40 is arranged side by side on the side of the conveyor belt 340, and the glue spreader 50 is located at the downstream of the back-end comb machine 40 along the conveying direction of the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com