Production technology of wood fiber bundle floor and product

A technology of wood fiber and production process, applied in the production process and product field of wood fiber bundle wood floor, can solve problems such as insignificant effect, and achieve the effects of superior performance, natural and simple appearance, good dimensional stability and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the production technology of wood fiber bundle wooden floor, this technique rolls poplar into strip fiber bundle, then strip fiber bundle and melamine modified urea-formaldehyde resin adhesive (melamine modified urea-formaldehyde resin adhesive can be purchased from the market) (obtained) mixed and placed in a mold, then hot-pressed at a temperature of 110° C. and a pressure of 3.0 MPa for 10 minutes to obtain a finished product.

Embodiment 2

[0018] Embodiment 2: The production process of wood fiber bundle wood flooring, this process willow willow is rolled into strip fiber bundle, then the strip fiber bundle and phenolic resin adhesive are mixed and placed in the mold, and then the temperature is 125 ℃, pressure 3.0 MPa hot pressing for 5 minutes to obtain the finished product.

Embodiment 3

[0019] Embodiment 3: The production process of wood fiber bundle wood flooring, this process will roll Chinese fir into strip-shaped fiber bundles, then place the strip-shaped fiber bundles and phenolic resin adhesive in the mold, and then use temperature 120 ℃, pressure 1.0 MPa hot pressing for 20 minutes to obtain the finished product.

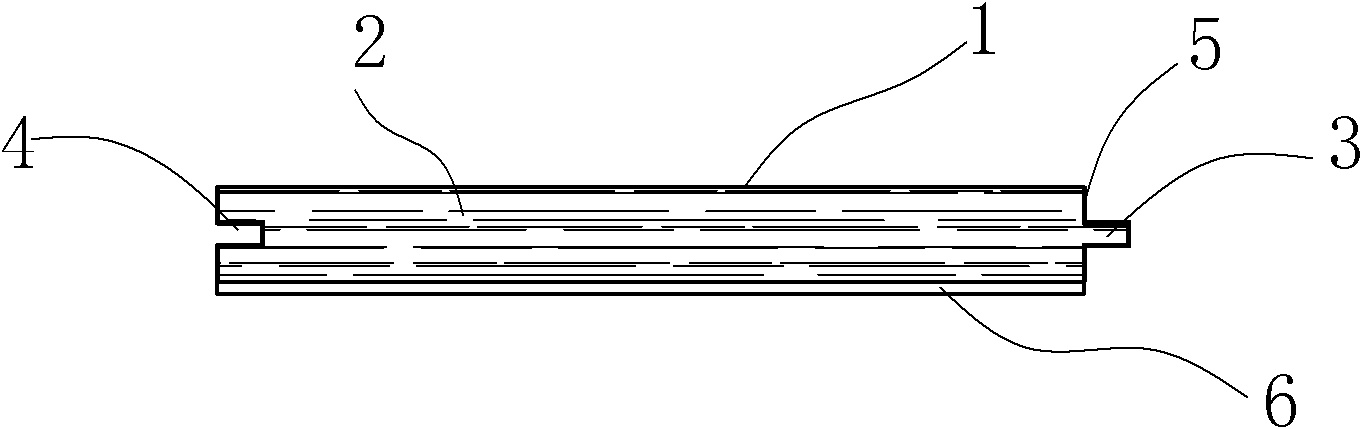

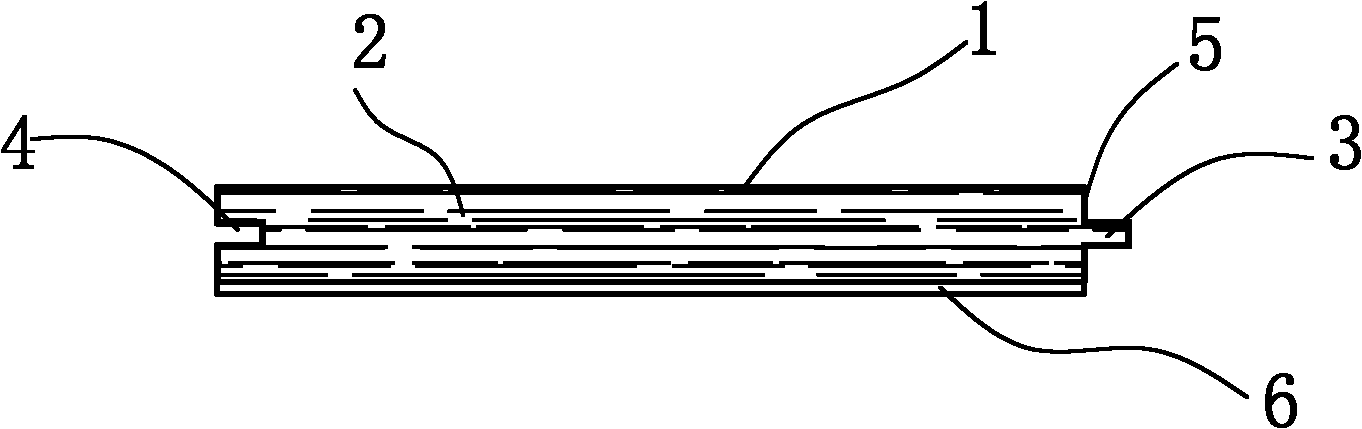

[0020] The wooden floor produced according to above-mentioned three kinds of embodiments, as attached figure 1 As shown, it includes a substrate 1, which is composed of strip-shaped fiber bundles 2; tenon 3 and tenon groove 4 are provided around the substrate 1, and a paraffin layer 5 is provided on the sides of the tenon 3 and tenon groove 4; the bottom of the substrate 1 is provided with a balance Paper 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com