Restructured wooden floor and preparation method thereof

A technology for reorganizing wood and flooring, which is applied in the field of wooden flooring and can solve problems such as ineffective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

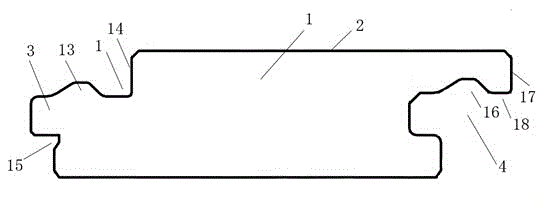

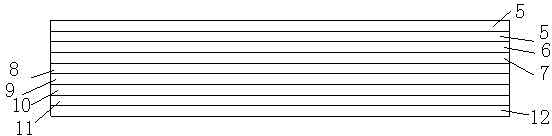

[0024] A reconstituted wooden floor, such as the attached figure 1 and 2 As shown, it includes a reconstituted wood core board 1 made of sticking and pressing fiber strips. The surface of the recombined wood core board is provided with a paint layer 2 , and side tenons 3 and side grooves 4 are provided on the side of the recombined wood core board. The paint layer 2 includes two scratch-resistant paint layers 5, a first wear-resistant paint layer 6, a touch-up paint layer 7, a second wear-resistant paint layer 8, a flexible paint layer 9, and a third wear-resistant paint layer from top to bottom. Paint layer 10, resin layer 11 and adhesive layer 12. The top of the side tenon 3 is provided with a trapezoidal protrusion 13, the trapezoidal protrusion 13 and the tenon side 14 are provided with an inner groove 15, and the lower part of the side tenon 3 is provided with a ventilation groove 16; the upper corner of the tenon side 14 is provided with 45 degrees, the bottom of the ...

Embodiment 2

[0032] Embodiment 2: the adhesive used for sticking the fiber strips includes 10 parts of phenolic glue, 26 parts of nitrile rubber, 7 parts of polyether glycol with a relative molecular weight of 2000, 3 parts of EDA, 2 parts of TMP, 5 parts of DMPA, and a toughening agent 20 parts, 15 parts of diluent and 0.9 parts of accelerator.

Embodiment 3

[0033] Embodiment 3: the adhesive used for pasting the described fiber strips includes 29 parts of phenolic glue, 13 parts of nitrile rubber, 6 parts of polyether glycol with a relative molecular weight of 2000, 5 parts of EDA, 4 parts of TMP, 2 parts of DMPA, and a toughening agent 12 parts, 18 parts of diluent and 4 parts of accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com