Preparation method of methyl phenyl hydrogen-containing silicone oil for LED packaging adhesive

A technology of LED encapsulation and methylphenyldimethoxysilane is applied in the field of preparation of methylphenyl hydrogen-containing silicone oil for LED encapsulation glue, which can solve the difficulty and cost of increasing production, poor repeatability and controllability, The preparation process is complicated and the operation is complicated, and the post-processing process is simple, the repeatability and controllability are good, and the process operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

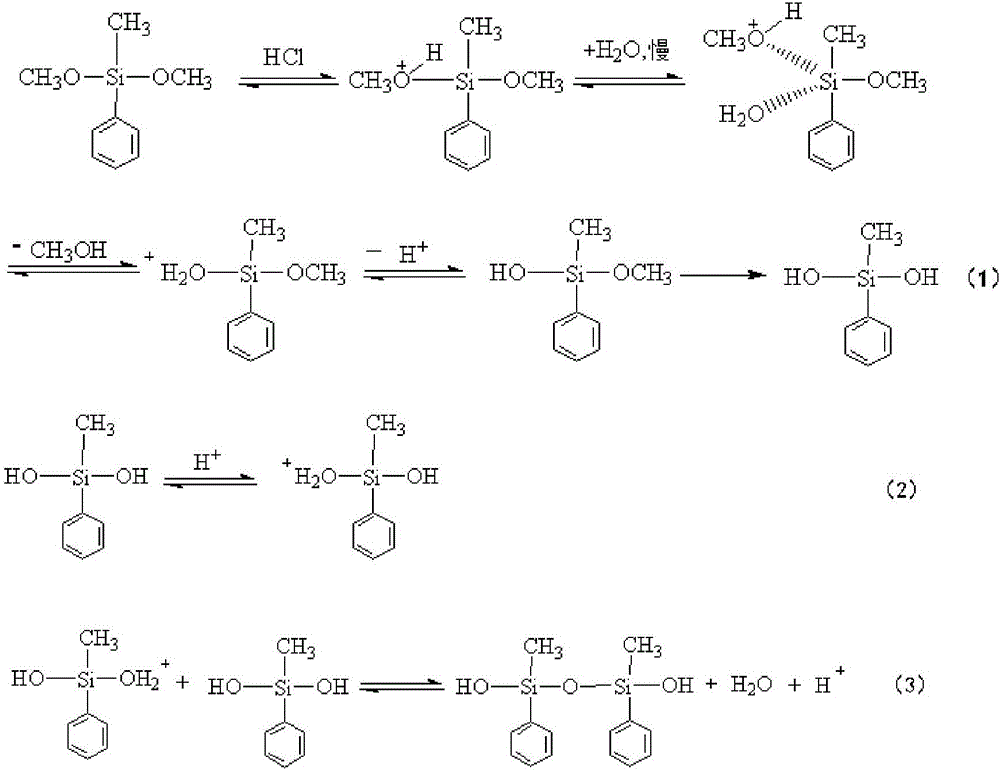

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 40g of hydrochloric acid with a mass fraction of 2.0% and add it to a four-necked flask equipped with mechanical stirring and temperature controller to preheat to 60°C, then add 50g of methylphenyldimethoxysilane at 60°C React for 2 hours. After the reaction is over, wash the product with distilled water for 3-4 times to neutrality, then transfer the product to a round-bottomed distillation flask and remove the water in the system at 80°C / -0.096MPa to obtain a colorless and transparent methyl phenyl hydroxyl terminated silicone oil.

[0026] (2) Take 30g of the above-prepared methyl phenyl hydroxyl-terminated silicone oil and add it to a three-necked flask equipped with mechanical stirring and a temperature controller to preheat to 60°C, and then add 0.89gMM H The end-capping agent and 0.31g CH-01 type acidic cationic resin were reacted at 60°C for 4 hours. After the reaction is over, remove the CH-01 type acidic cationic resin catalyst by suction filtration,...

Embodiment 2

[0028] (1) Take 40g of hydrochloric acid with a mass fraction of 2.0% and add it to a four-necked flask equipped with mechanical stirring and temperature controller to preheat to 60°C, then add 50g of methylphenyldimethoxysilane at 60°C React for 2 hours. After the reaction is over, wash the product with distilled water for 3-4 times to neutrality, then transfer the product to a round-bottomed distillation flask and remove the water in the system at 80°C / -0.096MPa to obtain a colorless and transparent methyl phenyl hydroxyl terminated silicone oil.

[0029] (2) Get 30g of the above-mentioned prepared methyl phenyl hydroxyl-terminated silicone oil and 15g of D 4 H Add it into a three-necked flask equipped with mechanical stirring and a temperature controller and preheat it to 60°C, then add 1gMM end-capping agent and 0.46gCH-01 type acidic cationic resin and react at 60°C for 4 hours. After the reaction is over, remove the CH-01 type acidic cationic resin catalyst by suction...

Embodiment 3

[0031] (1) Take 40g of hydrochloric acid with a mass fraction of 2.0% and add it to a four-necked flask equipped with mechanical stirring and temperature controller to preheat to 60°C, then add 50g of methylphenyldimethoxysilane at 60°C React for 2 hours. After the reaction is over, wash the product with distilled water for 3-4 times to neutrality, then transfer the product to a round-bottomed distillation flask and remove the water in the system at 80°C / -0.096MPa to obtain a colorless and transparent methyl phenyl hydroxyl terminated silicone oil.

[0032] (2) Take 30g of the above-mentioned prepared methyl phenyl hydroxyl-terminated silicone oil and 15g of D 4 H Add it to a three-necked flask equipped with mechanical stirring and a temperature controller, preheat to 60°C, and then add 1gMM H The end-capping agent and 0.46g CH-01 type acidic cationic resin were reacted at 60°C for 4 hours. After the reaction is over, remove the CH-01 type acidic cationic resin catalyst by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com