A method for detecting the filling flow rate of thick fluid

A flow detection and fluid technology, applied in the field of thick fluid filling flow detection, can solve the problems of increased instrument measurement error, limited production speed, inappropriateness, etc., achieve high detection accuracy and improve filling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

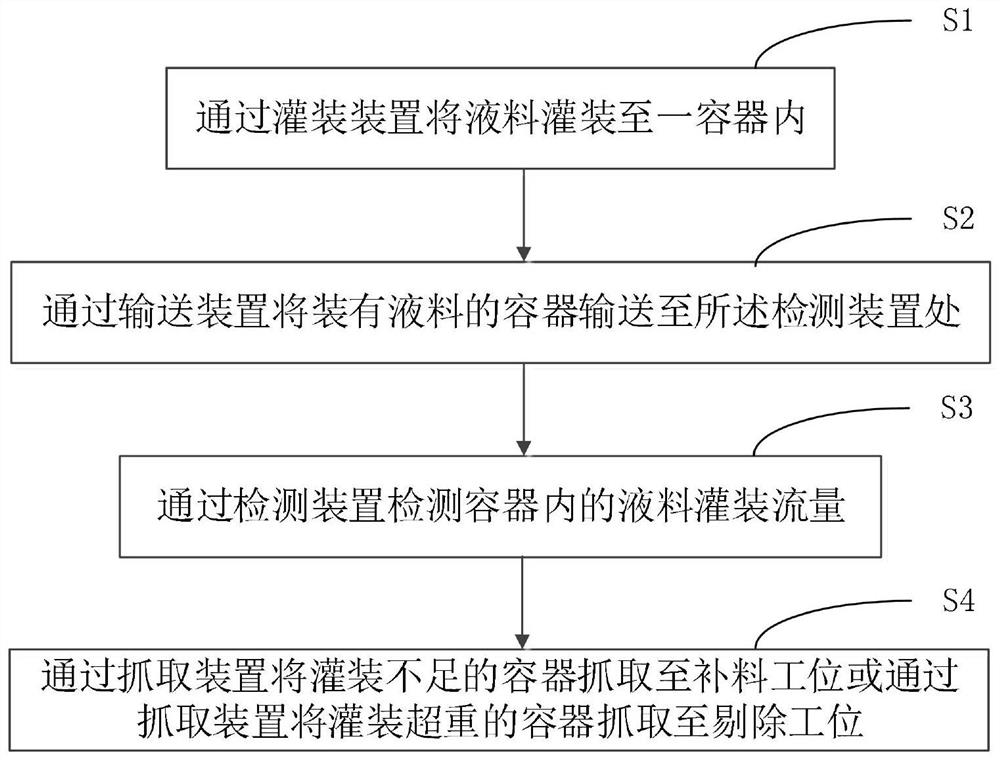

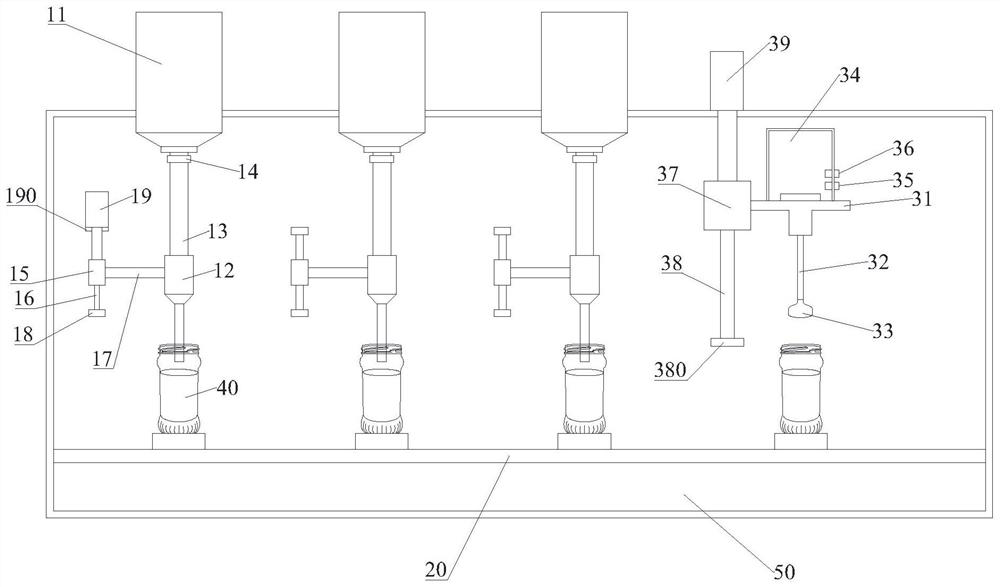

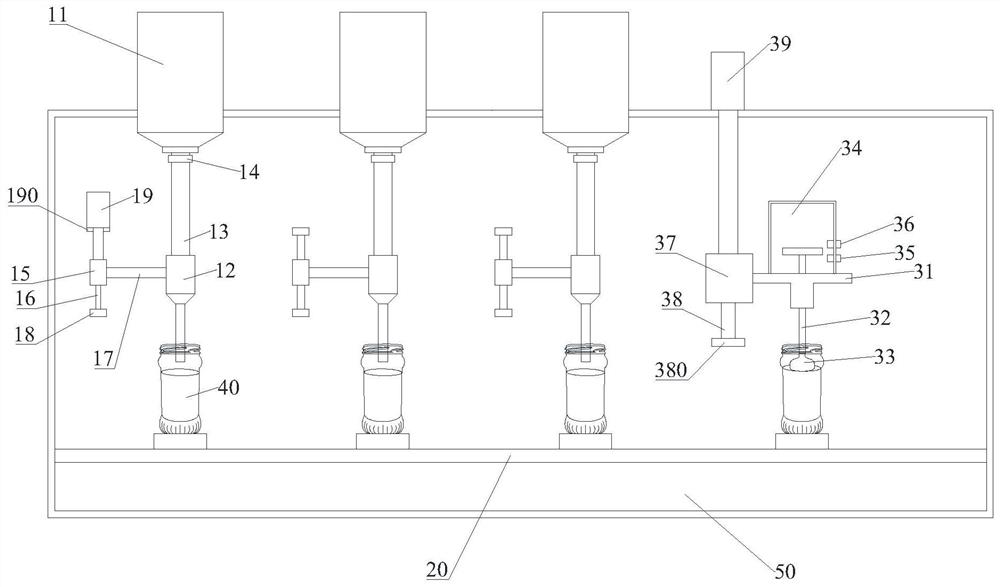

[0035] like figure 1 and figure 2 As shown, this embodiment provides a thick fluid filling flow detection method, including:

[0036] Step S1, filling the liquid material into a container 40 through the filling device 10;

[0037] When liquid material needs to be filled, the control module controls the nozzle driving mechanism to drive the nozzle 12 to move downward, so that the feeding end of the nozzle 12 extends into the mouth of the container; and the control module is suitable for controlling the solenoid valve 14 Open, so that the liquid material in the material tank 11 flows into the material nozzle 12 through the material pipe 13 and then flows into the container 40;

[0038] Step S2, transport the container 40 containing the liquid material to the detection device 30 through the conveying device 20; when the container containing the liquid material is transported to the detection device 30, control the lifting drive in the detection device through the control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com