Three-color wire cable jacket extrusion mold

A cable and sheath technology, which is applied in the field of three-color cable sheath extrusion molds, can solve the problems of ineffective prevention of ultraviolet radiation, expensive colored cables, and lack of quick resolution, etc., to achieve easy installation and debugging , more recognizable, recognizable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

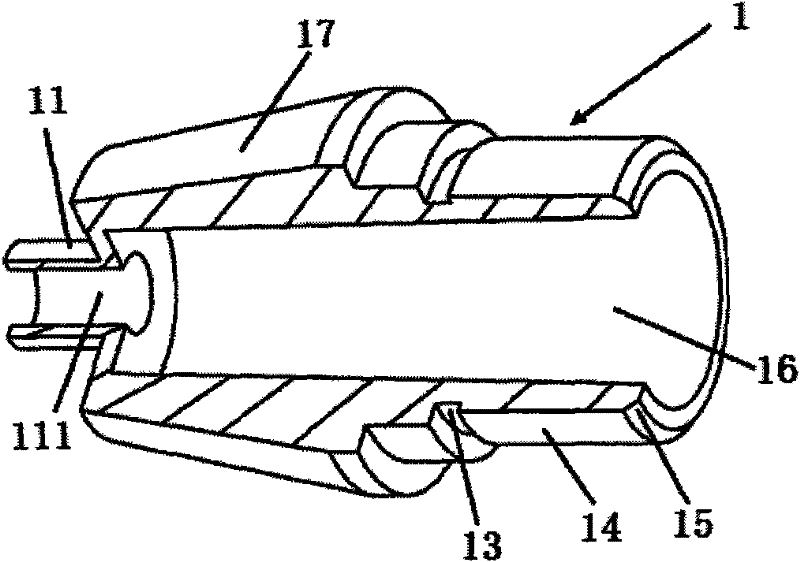

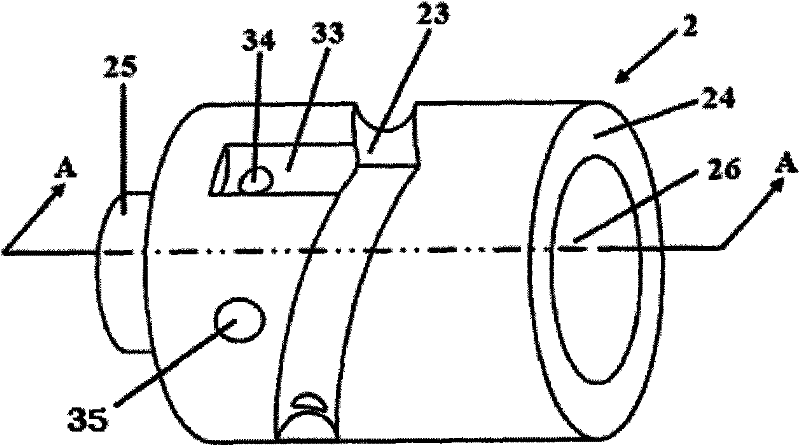

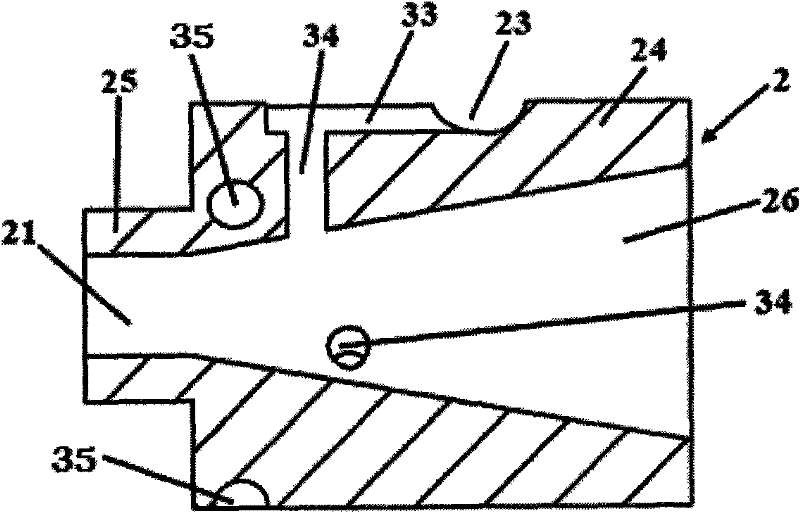

[0036] See Figure 1 to Figure 9, a three-color cable sheath extrusion mold, which includes: a core unit 1, a first cover unit 2 and a mold cover unit 3; the core unit 1 has a cable stem 11 at the front end, and a core body 17 in the middle. The clamping part 13 has a fixed part 14 at the rear end, a screw thread is provided on the fixed part 14, a chamfer 15 is provided on the end of the fixed part 14, and a hollow core cavity 16 is arranged inside the mold core unit 1; the cable core column 11 There is a cable core hole 111 inside, and the cable core hole 111 is connected with the mold core cavity 16. The mold core unit 1 is an integrated structure; the first mold cover unit 2 is composed of the discharge end 25 at the front end and the rear The mold cover body 24 at the end is formed, the mold cover body 24 is provided with a mold cover cavity 26 inside, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com