Oil seal

An oil seal and sealing lip technology, which is applied to engine components, engine seals, mechanical equipment, etc., can solve the problems of bad sealing effect, easy roll-up operability of the sealing lip 100, and difficulty in forming, so as to improve the sealing performance, Improves fluid lubrication effect, reduces sliding torque and sliding heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

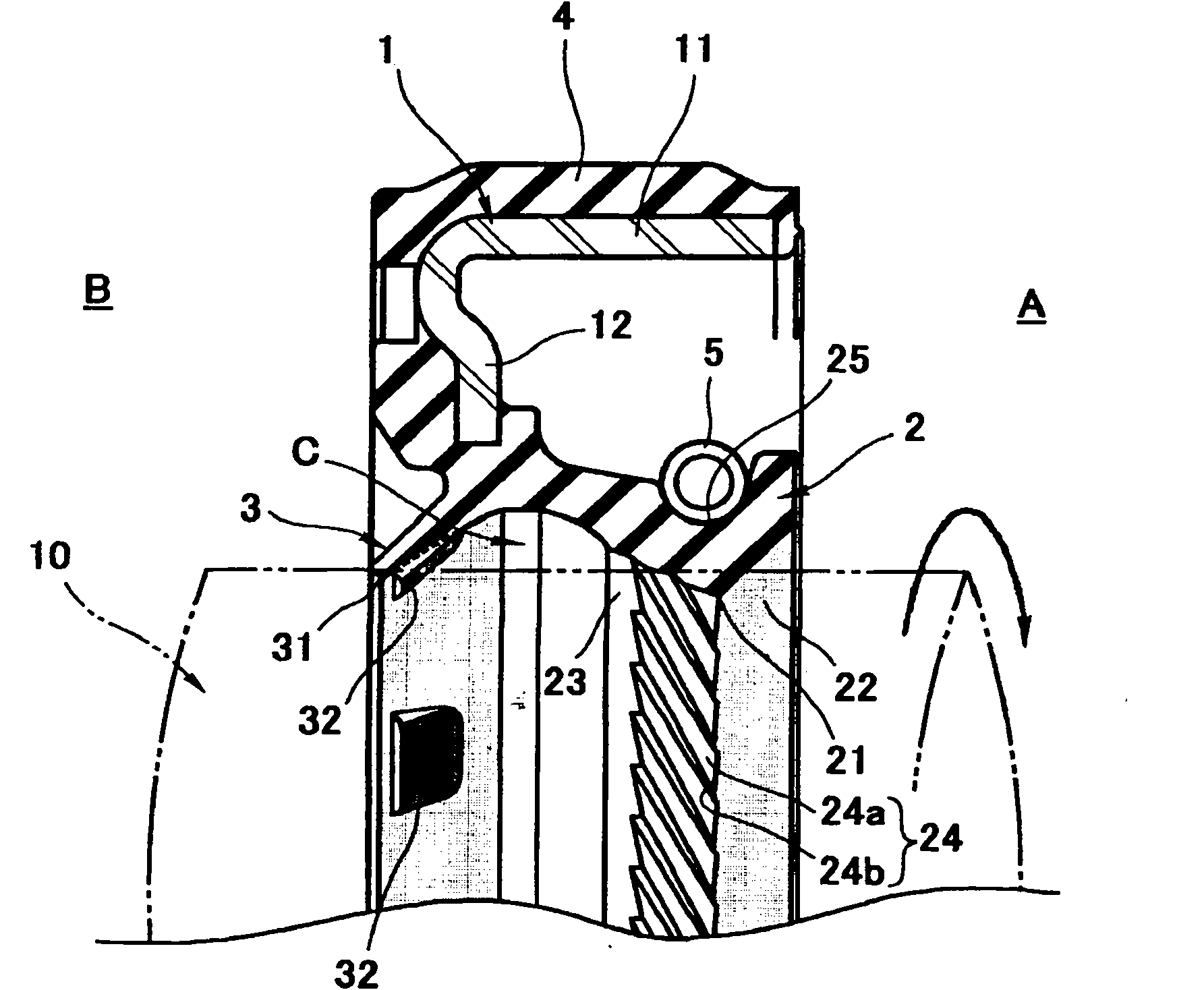

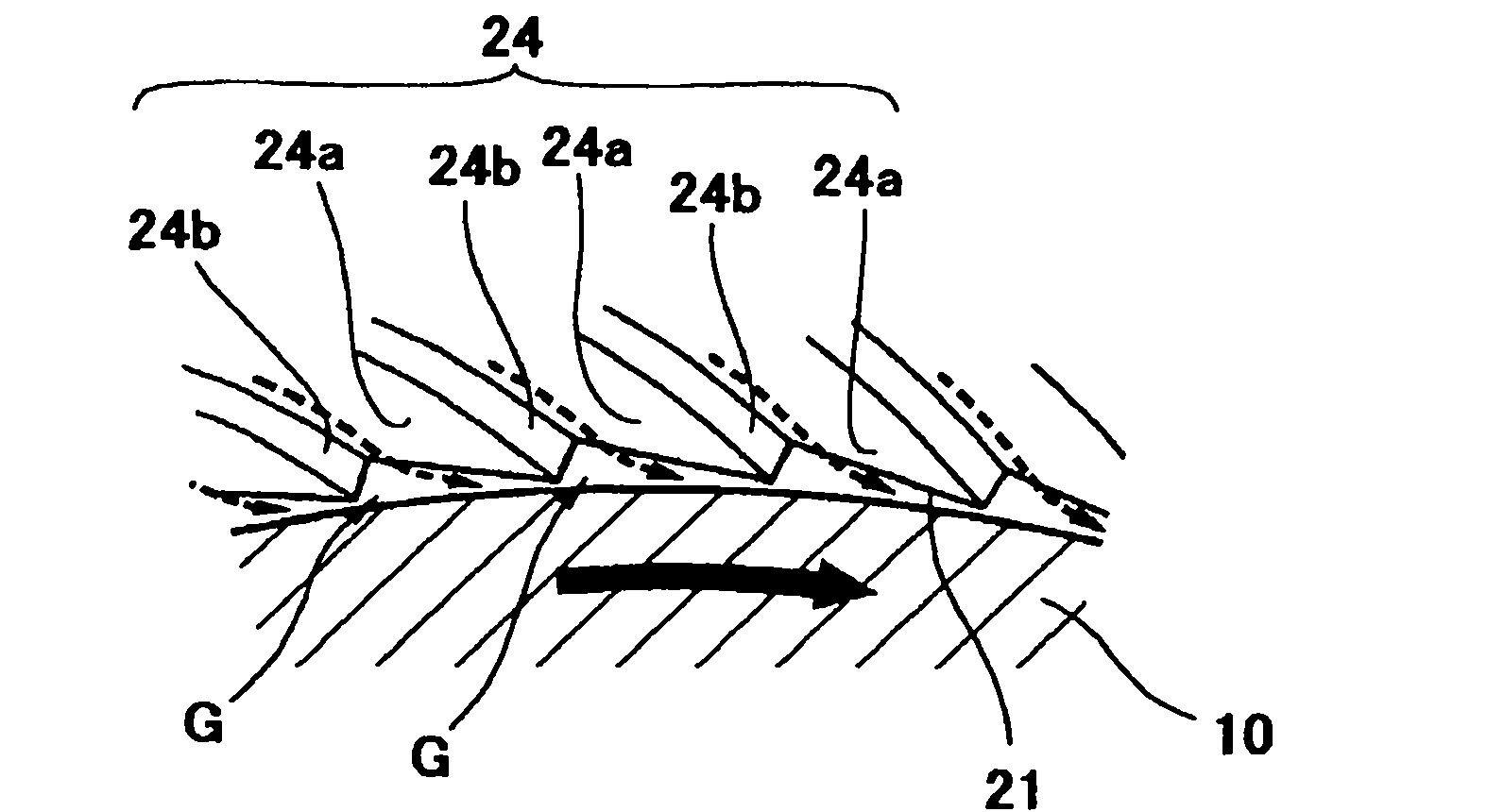

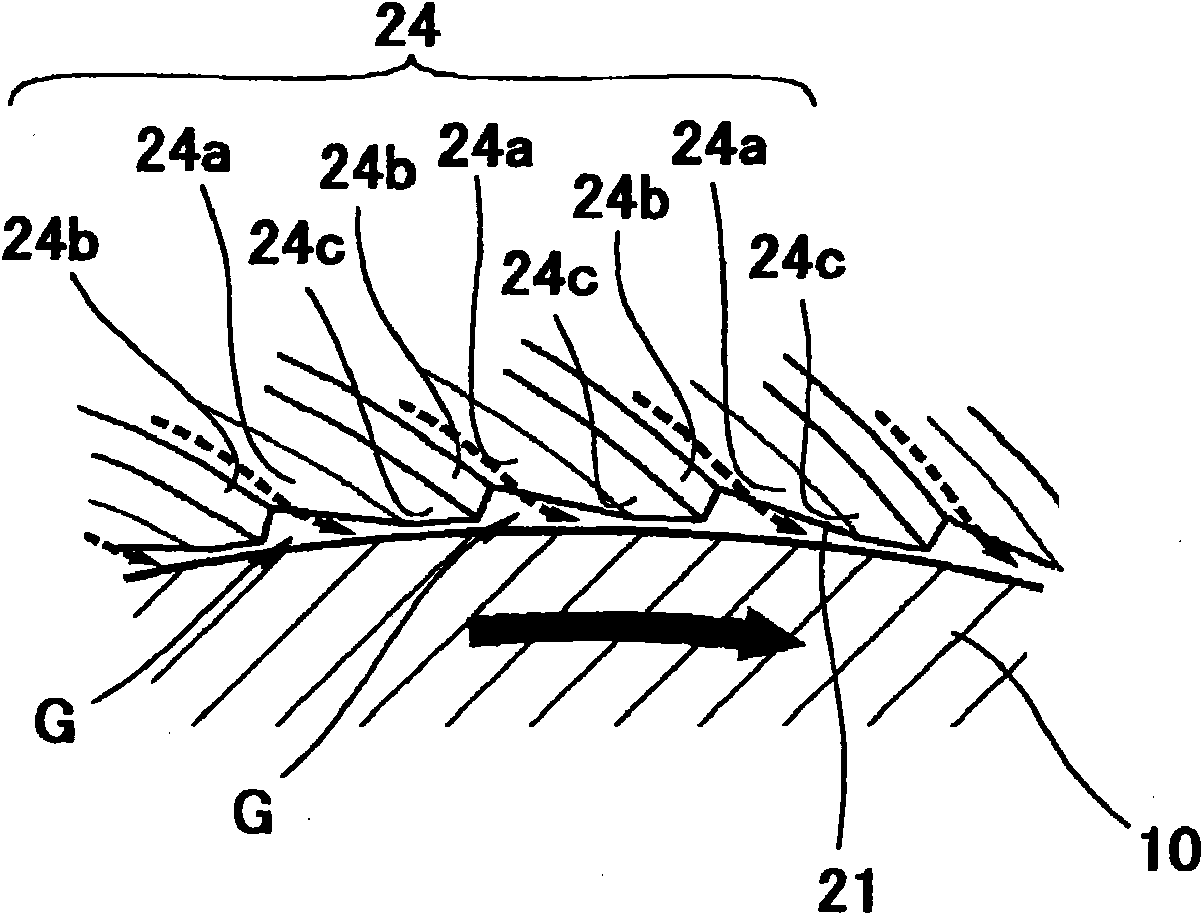

[0044] Hereinafter, a preferred embodiment of the oil seal of the present invention will be described with reference to the drawings. First of all, figure 1 It is a single-sided cross-sectional view of the first embodiment of the oil seal of the present invention taken with a plane passing through the axis, figure 2 It is an explanatory diagram showing the shape and function of the uneven stripe of the sealing lip of the first embodiment.

[0045] figure 1 The oil seal shown in the metal ring 1 is integrally provided with a sealing lip 2, a dust-proof lip 3, and a fixed sealing portion 4. The sealing lip 2, the dust-proof lip 3 and the fixed sealing portion 4 on the outer peripheral side are made of a rubber-like elastic material and connected to each other. In addition, a clamping coil spring 5 is mounted on the outer peripheral surface near the front end of the sealing lip 2.

[0046] The metal ring 1 is a press-formed product such as a steel plate, and has an outer periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com