Method for preparing putty powder excellent in cracking resistance

A kind of putty powder, excellent technology, used in biocide-containing paints, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve problems such as unstable calcium oxide and calcium hydroxide, poor waterproof performance, and weak adhesion , to achieve the effect of good flatness, excellent water resistance, and little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

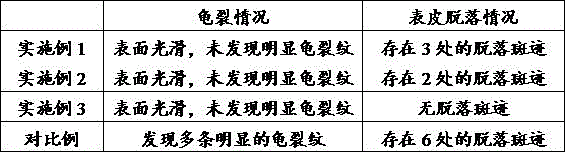

Embodiment 1

[0025] Putty powder with excellent anti-crack performance, the putty powder is processed from the following raw materials in parts by weight: 20 parts of white cement, 10 parts of calcium bicarbonate, 25 parts of talcum powder, 25 parts of ash calcium powder, and 2 parts of rubber powder;

[0026] The preparation method of described rubber powder comprises the steps:

[0027] (1) Prepare the main ingredient: use phenolic resin powder as the base material, adjust the pH value to neutral, raise the temperature to 50°C, add an appropriate amount of epoxy resin, maintain a constant temperature reaction for 15 minutes, and then cool to room temperature;

[0028] (2) Preparation of functional agent: Proper amount of propolis powder, water-soluble dextran and antioxidant are thoroughly mixed and evenly heated to 60°C to form a stable molten viscous fluid, and particulate impurities are filtered out for later use;

[0029] (3) Preparation of finished rubber powder: the main agent and ...

Embodiment 2

[0035] Putty powder with excellent anti-crack performance, the putty powder is processed from the following raw materials in parts by weight: 30 parts of white cement, 20 parts of calcium bicarbonate, 35 parts of talcum powder, 35 parts of ash calcium powder, and 4 parts of rubber powder;

[0036] The preparation method of described rubber powder comprises the steps:

[0037] (1) Prepare the main ingredient: use phenolic resin powder as the base material, adjust the pH value to neutral, raise the temperature to 60°C, add an appropriate amount of epoxy resin, maintain a constant temperature for 5 minutes, and then cool to room temperature;

[0038] (2) Preparation of functional agent: Proper amount of propolis powder, water-soluble dextran and antioxidant are fully mixed and evenly heated to 70°C to form a stable molten viscous fluid, and particulate impurities are filtered out for later use;

[0039] (3) Preparation of finished rubber powder: the main agent and the functional ...

Embodiment 3

[0045] Excellent anti-crack performance putty powder, the putty powder is processed from the following raw materials in parts by weight: 25 parts of white cement, 15 parts of calcium bicarbonate, 30 parts of talcum powder, 30 parts of ash calcium powder, and 3 parts of rubber powder;

[0046] The preparation method of described rubber powder comprises the steps:

[0047] (1) Prepare the main ingredient: use phenolic resin powder as the base material, adjust the pH value to neutral, raise the temperature to 55°C, add an appropriate amount of epoxy resin, maintain constant temperature for 5 minutes, and then cool to room temperature;

[0048] (2) Preparation of functional agent: Proper amount of propolis powder, water-soluble dextran and antioxidant are fully mixed and evenly heated to 65°C to form a stable molten viscous fluid, and particulate impurities are filtered out for later use;

[0049] (3) Preparation of finished rubber powder: the main agent and the functional agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com