Kettle bell, kettle bell shell and production method of kettle bell

A shell and kettlebell technology, applied in the direction of dumbbells, heavy objects, etc., can solve the problems of small opening at the bottom of the shell, inconvenient operation, slow speed, etc., and achieve the effects of convenient cleaning and shaping, convenient infusion, and increased infusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

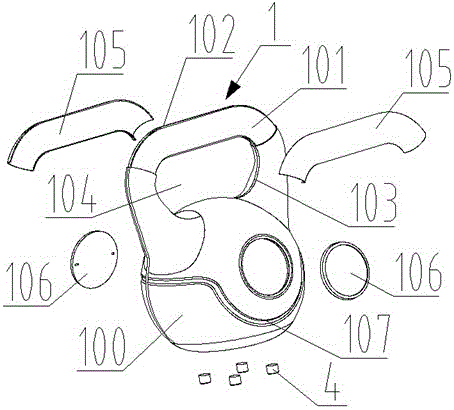

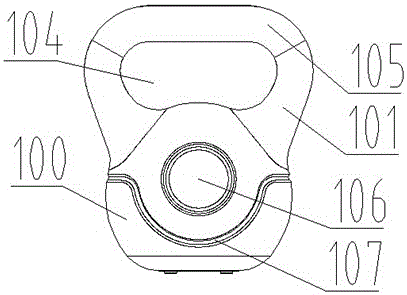

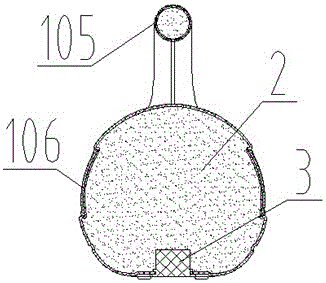

[0076] Such as figure 1 As shown, the embodiment of the present invention provides a kettlebell, including a kettlebell shell 1, which is a kettle-type plastic shell integrally blow-molded by the shell body 100 and the handle body 101, and the kettlebell shell 1 is blow-molded At the same time, an outer mold line 102 and an inner mold line 103 are formed at the mold clamping place. The outer mold line 102 circles around the kettlebell shell 1, and the inner mold line 103 surrounds the handle body 101 and the shell body 100. The through hole 104 has a circle.

[0077] The handle body 101 is composed of a handle beam and the handle bending parts at both ends thereof, and the front and rear sides of the handle beam are inlaid with Figure 5 Handle insert 105 is shown.

[0078] The back of the handle insert 105 is provided with a hook 1050 consisting of a protrusion and an elbow at the end of the protrusion. When the kettlebell shell 1 is blow-molded, the hook 1050 is stuck into...

Embodiment 2

[0109] Embodiment 2: as Figure 11 As shown, the difference between the structure of this embodiment and that of Embodiment 1 lies in the structure of the cover. The post in this embodiment is a threaded post, and a flange or a groove is provided at the lower part of the threaded post.

Embodiment 3

[0110] Embodiment 3: as Figure 12 As shown, the difference between the structure of this embodiment and that of Embodiment 1 lies in the structure of the cover. The column in this embodiment is changed to a cylinder integrally formed with the bottom plate, and a flange or a groove is provided at the lower part of the outer wall of the cylinder. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com