Single-rod multi-head transecting spiral submersible pump

A technology of submersible oil pump and screw, which is applied in the field of single-rod multi-head cross-cut screw submersible pump, which can solve the problems of fast wear of the stator sleeve, many stages of impellers, and short service life, and achieve fewer structural moving parts, strong discharge pressure, and easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

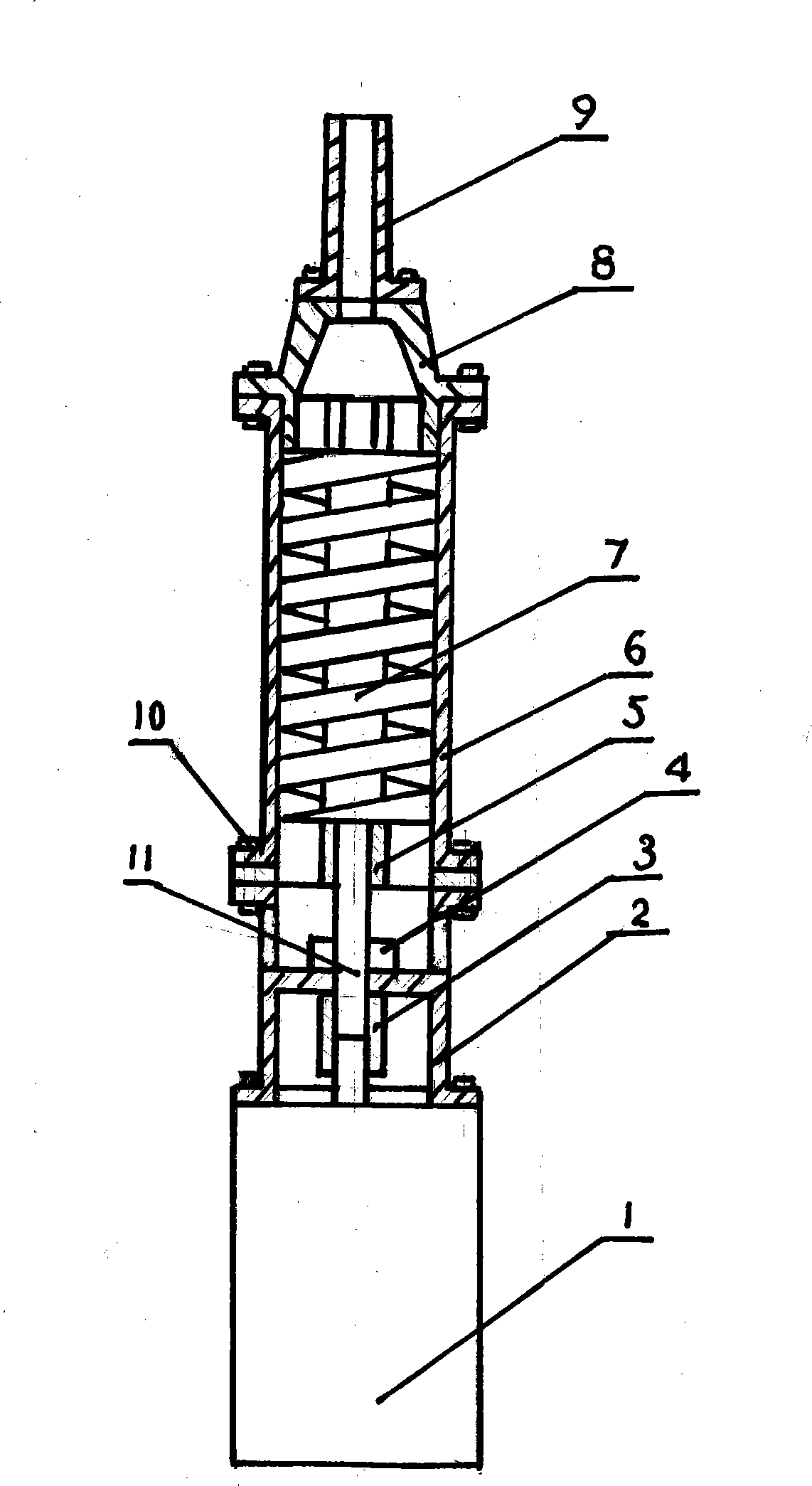

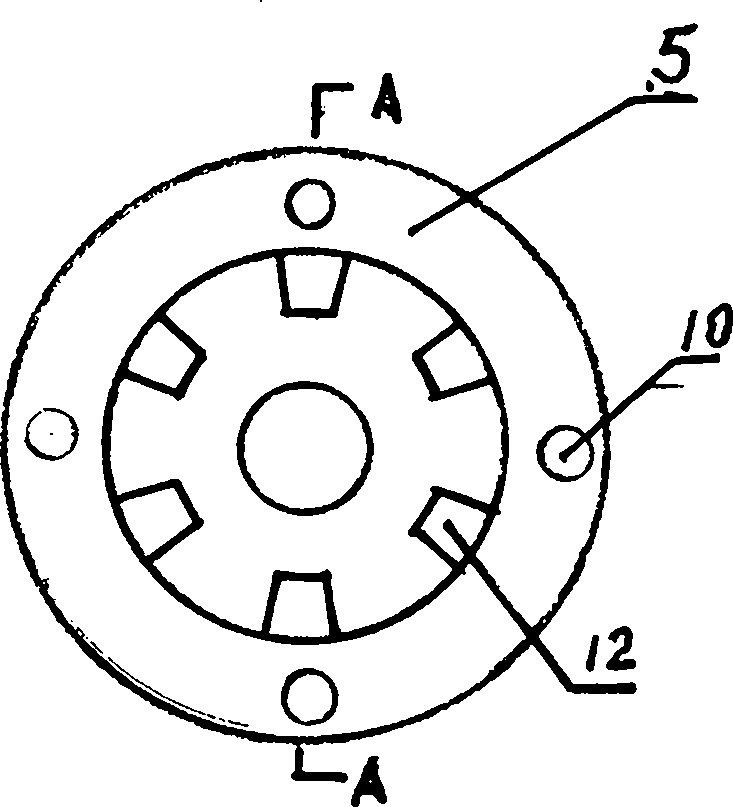

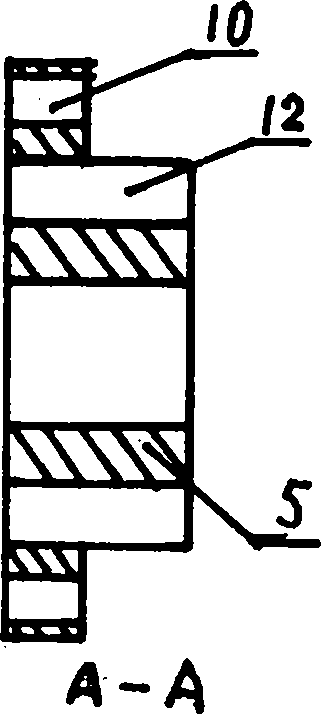

[0014] Embodiment 1, with reference to figure 1 , 2 , 4, a single-rod single-head cross-cut screw submersible pump, consisting of a submersible motor 1, a motor bracket 2, a coupling 3, a suction disc 5, a thrust bearing 4, a multi-head screw rotor 7, a housing 6, a collection and transportation Section 8, discharge pipe 9, and bolts 10, wherein the submersible motor 1 is connected to the suction disc 5 through the motor bracket 2, the coupling 3, the thrust bearing 4 is installed on the main shaft 11, and the multi-head helical rotor 7 is processed on the main shaft 11. The tooth end surface 13 of the multi-head helical rotor 7 cooperates with the rotating sliding surface of the suction disc 5 , the housing 6 is connected with the suction disc 5 through bolts 10 , and the upper end of the housing 6 is connected with the collecting joint 8 and the discharge pipe 9 .

[0015] Said silk sucking and sparse dish 5 has six suction and sparse holes 12 equally divided on the suction...

Embodiment 2

[0017] Embodiment 2, with reference to figure 1 , 2 , 3, a single-rod three-head cross-cut screw submersible pump, consisting of a submersible motor 1, a motor bracket 2, a coupling 3, a suction disc 5, a thrust bearing 4, a multi-head screw rotor 7, a housing 6, a collection and transportation Section 8, discharge pipe 9, and bolts 10, wherein the submersible motor 1 is connected to the suction disc 5 through the motor bracket 2, the coupling 3, the thrust bearing 4 is installed on the main shaft 11, and the multi-head helical rotor 7 is processed on the main shaft 11. The tooth end surface 13 of the multi-head helical rotor 7 cooperates with the rotating sliding surface of the suction disc 5 , the housing 6 is connected with the suction disc 5 through bolts 10 , and the upper end of the housing 6 is connected with the collecting joint 8 and the discharge pipe 9 .

[0018] Said silk sucking and sparse dish 5 has six suction and sparse holes 12 equally divided on the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com