Multi-cylinder radial piston pump

A radial piston pump and piston technology, applied in the field of volumetric pumps, can solve the problems of large liquid backflow and loss of volumetric efficiency, limited radial force of eccentric shaft, increased noise and vibration, etc. The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

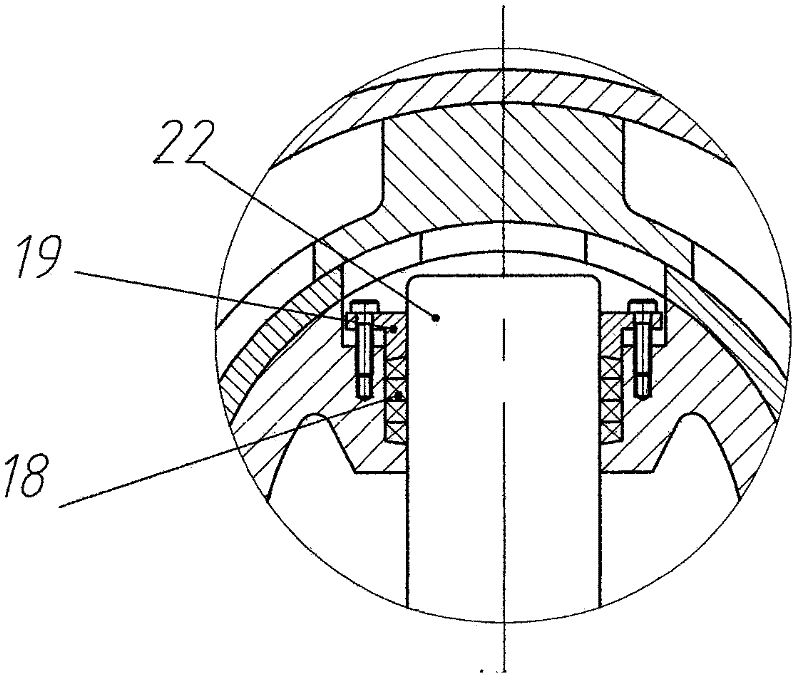

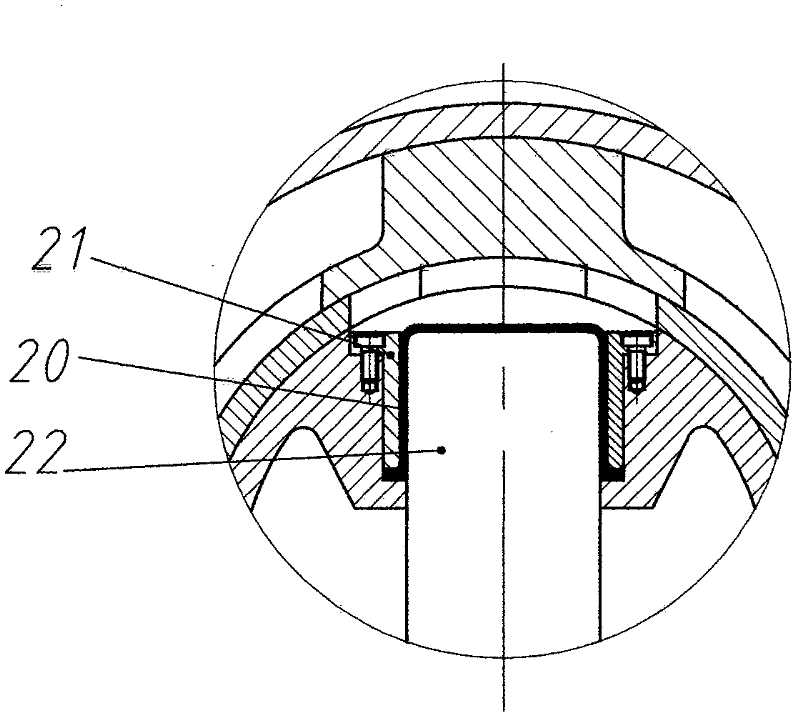

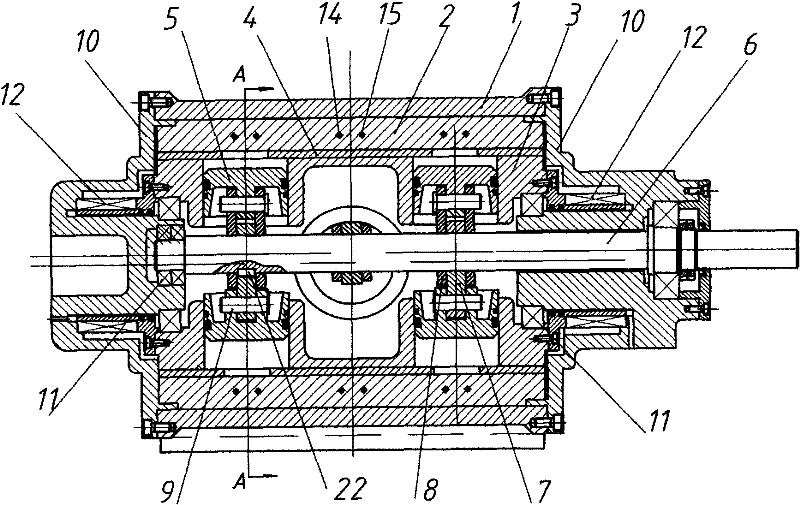

[0028] figure 1 , is a structural diagram of an embodiment of the present invention, and is a six-cylinder radial piston pump, figure 2 It is a cross-sectional view of A-A. In the figure, there are pump body 1, tongue sleeve 2, rotor 3, rotor sleeve 4, piston 5, eccentric shaft 6, connecting rod 7, auxiliary connecting rod 8, connecting rod pin 9, bearing body 10, shaft seal Device 12, septum tongue 13, suction check valve 14, discharge check valve 15, flat key 22.

[0029] This embodiment uses the movement principle of the eccentric mechanism to realize the suction and discharge function of the pump. When the motor drives the eccentric shaft 6 to rotate, the eccentric shaft 6 further drives the rotor 3 to rotate through the connecting rod 7 and the piston 5, and the piston 5 rotates around the eccentric shaft 6. One side makes relative reciprocating motion along the radial through hole on the rotor 3, the reciprocating stroke is twice the eccentricity of the eccentric shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com