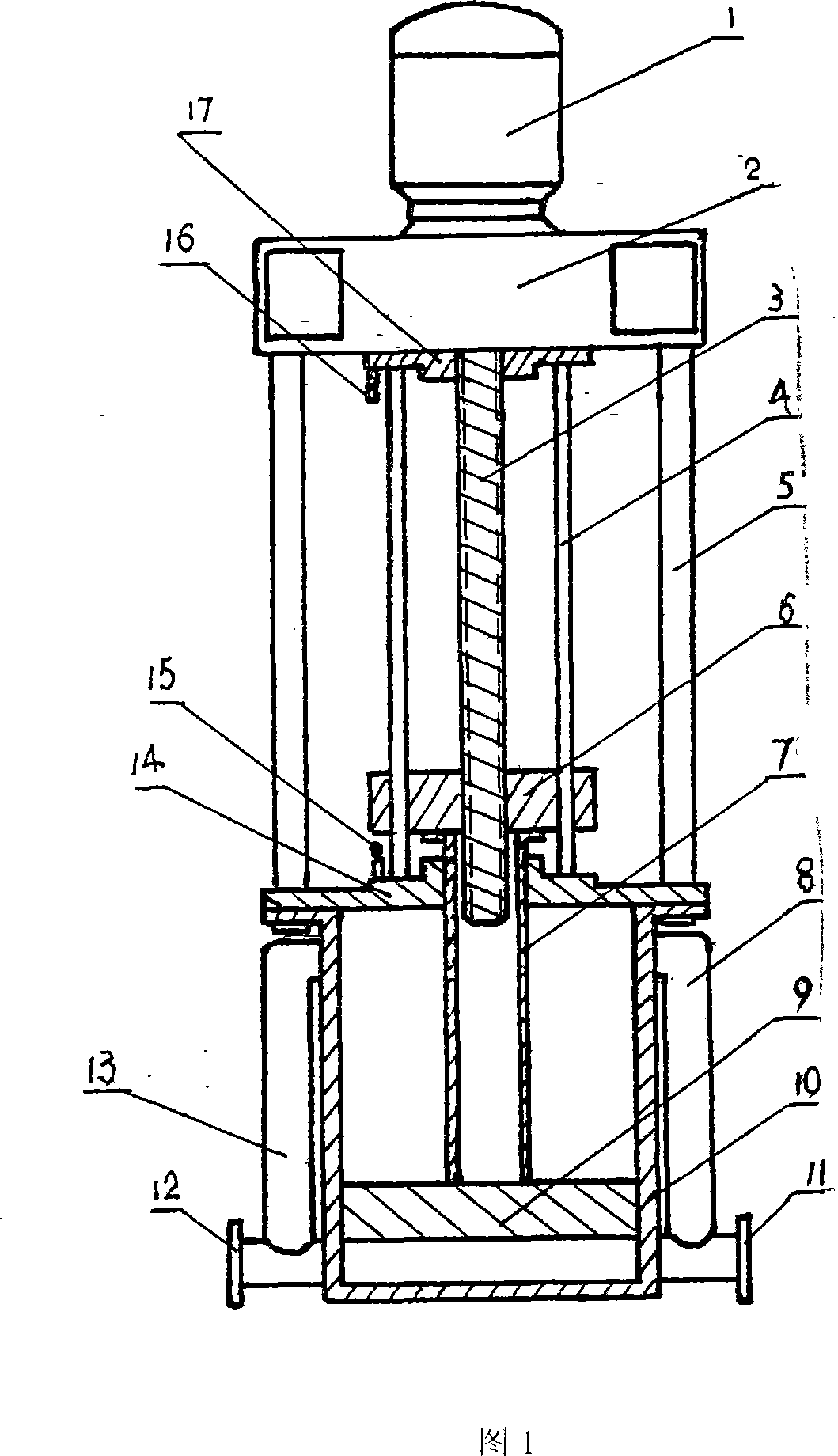

Screw piston pump

A piston pump and lead screw technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems of large capacity, long distance, poor transmission capacity of high-viscosity medium, low power source capacity, etc., and achieve structural movement. Fewer components, powerful power, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0012] Embodiment 2. A lead screw piston pump is composed of two single-cylinder lead screw piston pumps as described in embodiment 1 and combined to form a double-cylinder lead screw piston pump.

[0013] In the working state, when the piston is at the bottom of the cylinder, the lead screw pulls the piston upwards through the screw nut, and when it touches the upper limit switch, the screw nut moves down through the main shaft commutator and reciprocates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com