Hand pump type thick liquid packaging bottle

A technology for packaging bottles and caps, applied in the direction of liquid distribution, etc., can solve the problems of high cost, liquid discharge, complex structure, etc., and achieve the effects of low manufacturing cost, easy assembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

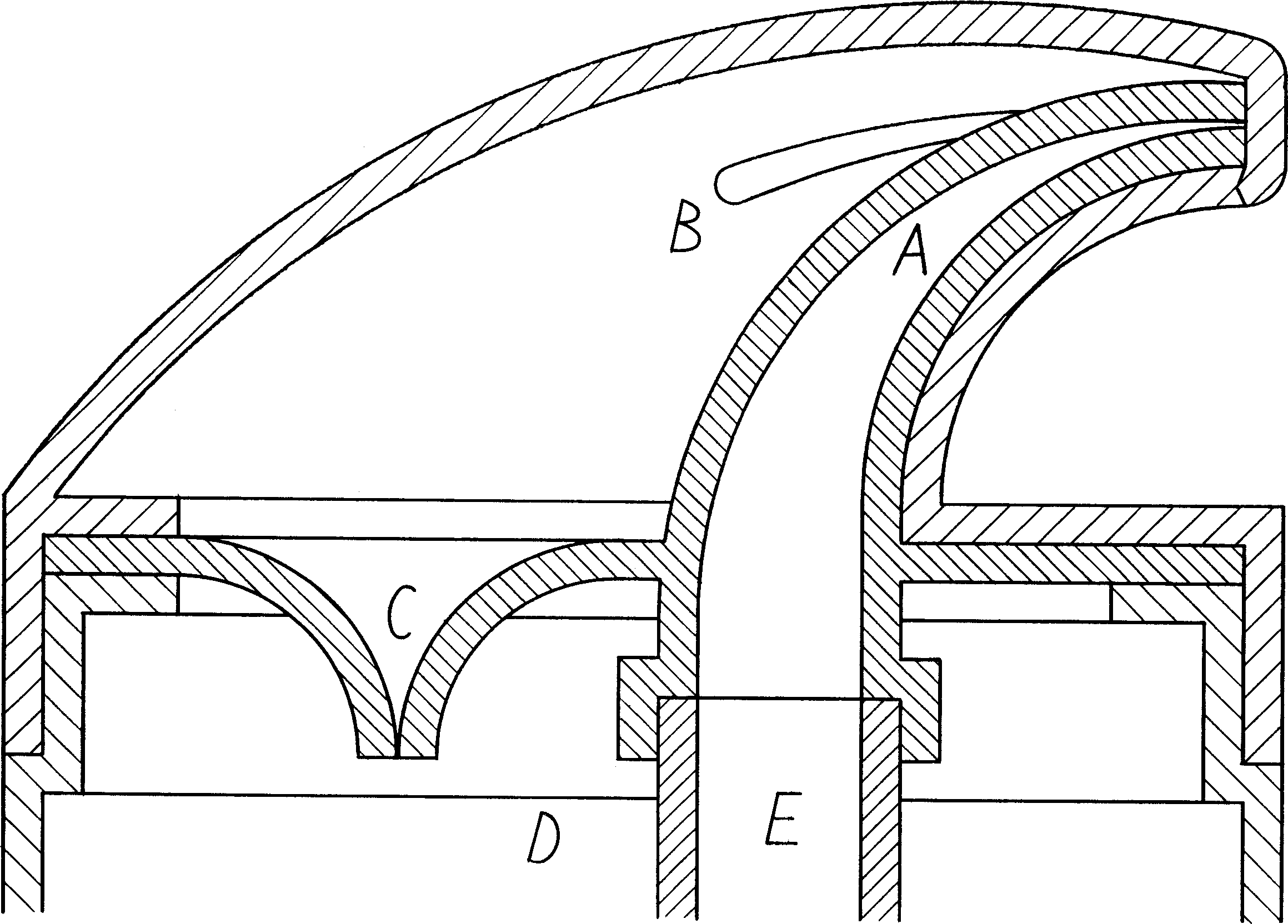

[0008] As shown in the figure, the elastic outlet air pressure valve A and the elastic inlet air pressure valve C are both made of elastic materials such as rubber. And juxtaposed into one. And be squeezed between the bottle body D and the bottle cap B. Thereby the bottleneck is closed, and only two one-way valves A and C are connected with the outside world. The lower end of the elastic outlet air pressure valve A is connected with a conduit E, and stretches to the bottom of the bottle.

[0009] The openings of the check valves A and C are flat, so they are normally closed. When the air pressure inside and outside the bottle is not equal, due to their own elasticity, their flat openings can be opened by the fluid from the larger flow section to the smaller flow section under the action of higher air pressure. . On the contrary, it is more tightly closed. Therefore, the A valve can only conduct to the outside of the bottle, and the C valve can only conduct to the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com