flow meter

A flowmeter and fluid technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve the problem of expensive gears, difficulty in small-scale implementation, strength, size, and use of magnetic gear flowmeters Restrictions and other issues to achieve the effect of easy production and reduced possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following detailed description is exemplary in nature and is not intended to limit the scope, applicability, or configuration of the invention in any way. Rather, the following description provides practical illustrations for implementing exemplary embodiments of the invention. Examples of structures, materials, dimensions, and manufacturing processes are provided for selected elements, and all other elements employ those known to those skilled in the art. Those skilled in the art will recognize that many of the examples provided have suitable alternatives available.

[0024] The term "fluid" is used herein to identify any continuous substance that tends to flow or conform to the contours of its container. The term fluid therefore includes both liquids and gases. A particularly interesting use of the invention is with liquids, especially liquid products and chemicals used in cleaning, washing, sanitizing, rinsing and the like.

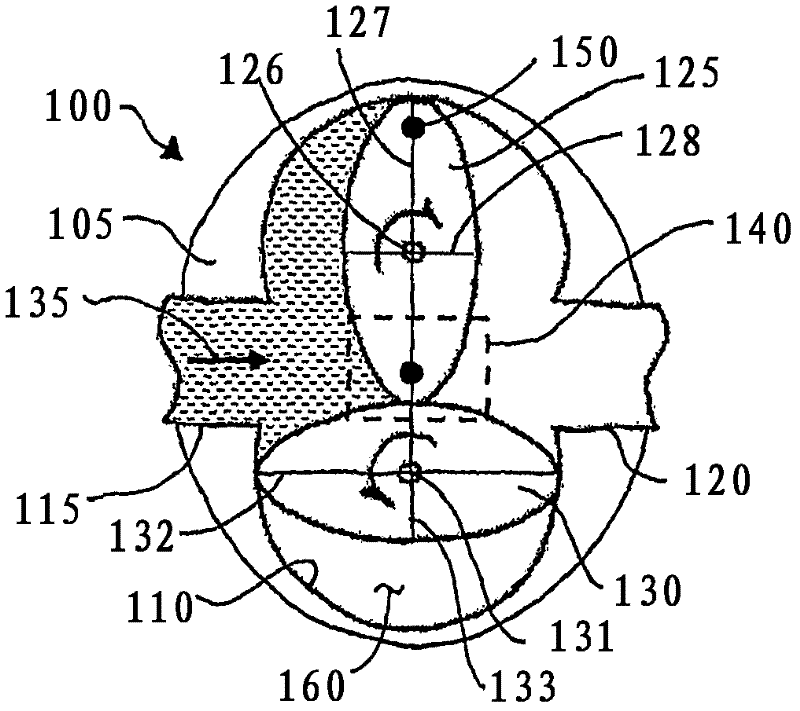

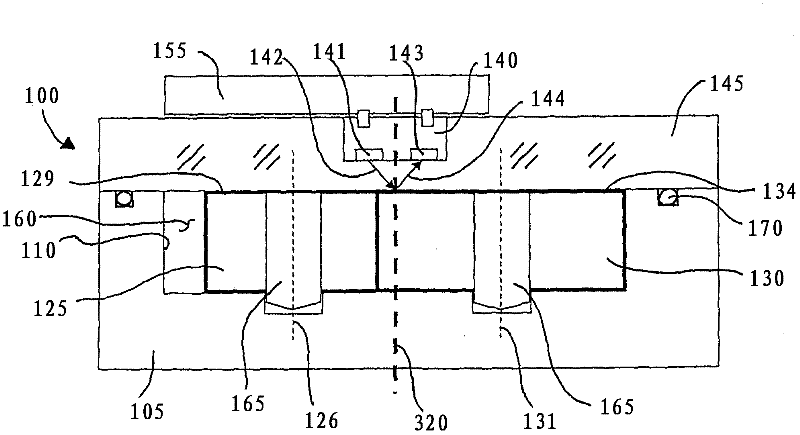

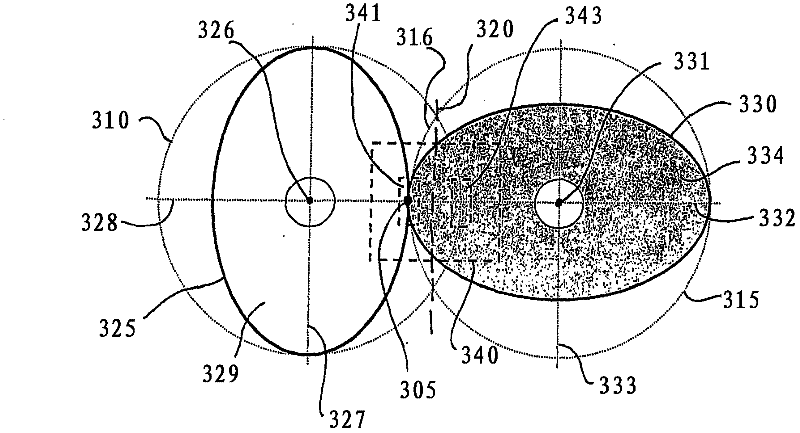

[0025] figure 1 and 2 A view is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com