Flexible display device manufacturing method and carrier substrate for manufacturing same

A technology for flexible display devices and carrier substrates, which is applied in tube/light screen manufacturing, printed circuit manufacturing, chemical instruments and methods, etc., can solve problems such as difficult operation, and achieve the effect of reducing the possibility of product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

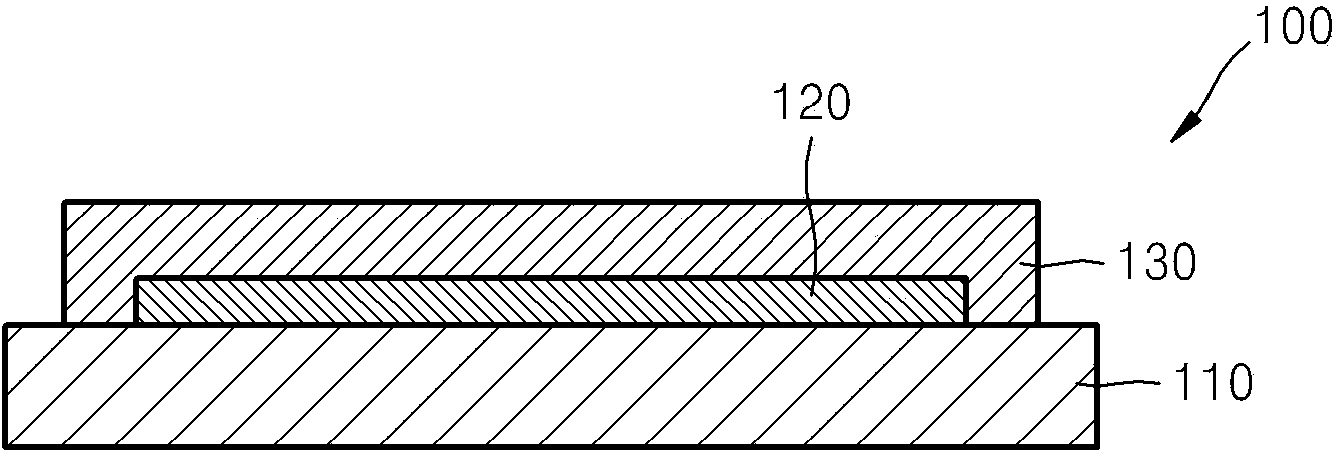

[0038] figure 1 is a cross-sectional view briefly illustrating a flexible display device 100 according to an embodiment of the present invention, in which a top emission type is shown.

[0039] As shown in the figure, the flexible display device 100 of this embodiment is sequentially stacked with an ultra-thin base substrate 110 with a thickness of 50-100 μm, a display portion 120 for presenting images, and a packaging substrate 130 for sealing the display portion 120 . That is, the figure shows a flexible structure in which the display unit 120 is sealed with an extremely thin glass base substrate 110 and a thin-film packaging substrate 130 instead of the conventional thick and hard glass substrate.

[0040] Therefore, compared with the conventional typical structure in which the display unit 120 is surrounded by a thicker glass subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com