Automatic filling equipment for emulsion skin care product

A technology for automatic filling and skin care products, which is applied in liquid bottling, packaging, bottle filling, etc. It can solve the problems of lower production efficiency, high equipment cost, and prolong production time, so as to prevent liquid leakage, simple device structure, and guarantee uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

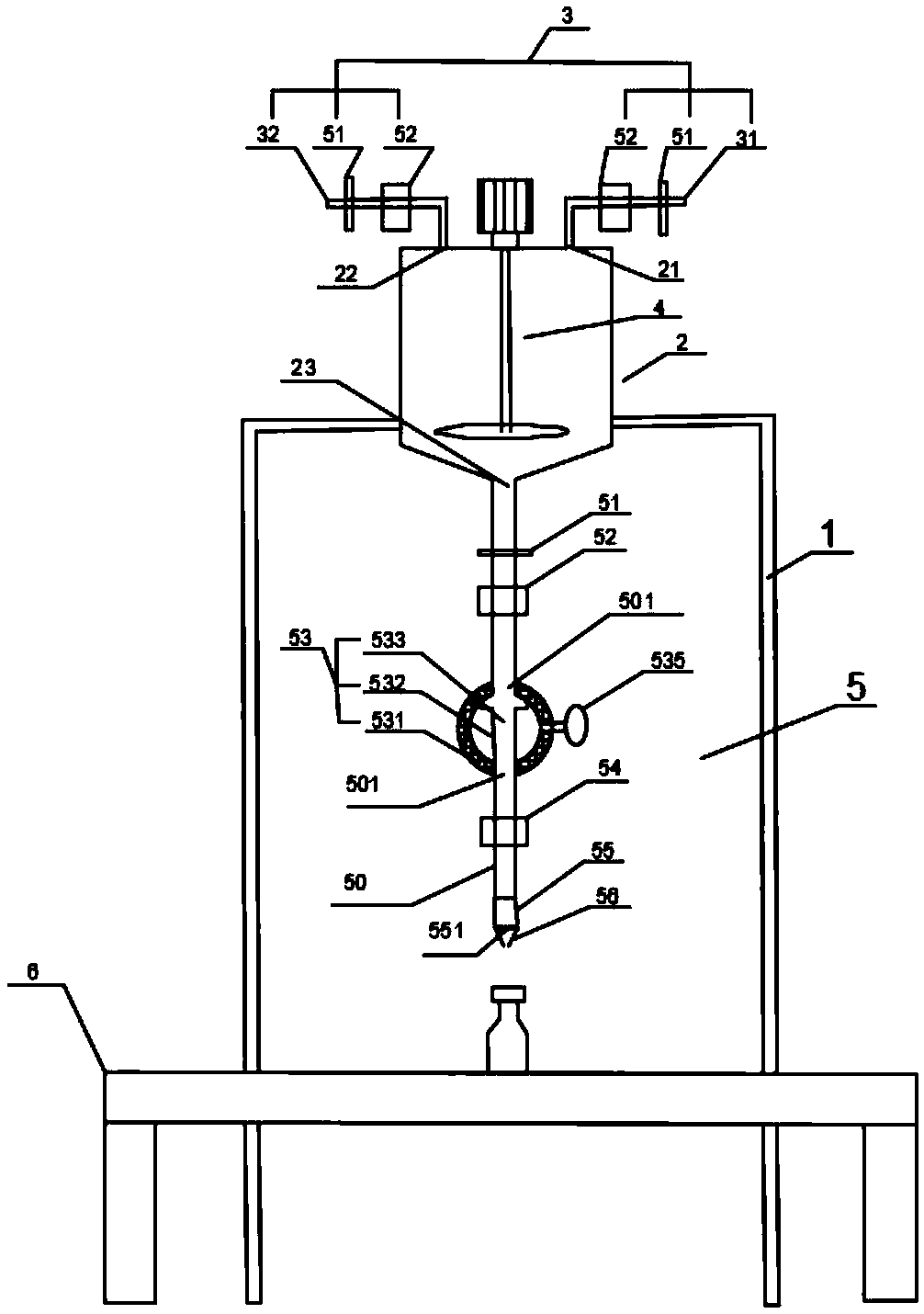

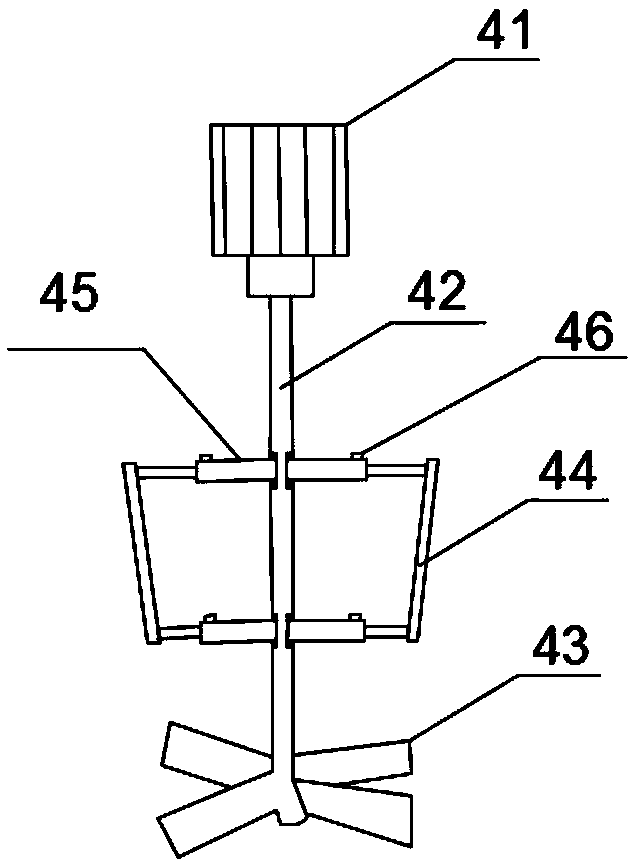

[0028] A kind of emulsion skin care product automatic filling equipment described in the present embodiment, combines figure 1 , figure 2For illustration, it includes a bracket 1, a mixing tank 2, a feeding device 3, an agitator 4, a filling mechanism 5 and a conveying device 6. The bottom of the bracket 1 is provided with a non-slip mat; the mixing tank 2 is fixedly arranged on the bracket 1; The device 3 is installed on the top of the mixing tank 2, and the feeding device 3 includes a first feed pipe 31 and a second feed pipe 32, and the first feed pipe 31 and the second feed pipe 32 pass through the top two sides of the mixing tank 2 respectively. The first feed port 21 and the second feed port 22 on the side communicate with the cavity of the mixing tank 2, and the first feed pipe 31 and the second feed pipe 32 are respectively equipped with an electronic flowmeter 52, an electromagnetically controlled pneumatic Valve 51, the skin care product raw material flows through ...

Embodiment 2

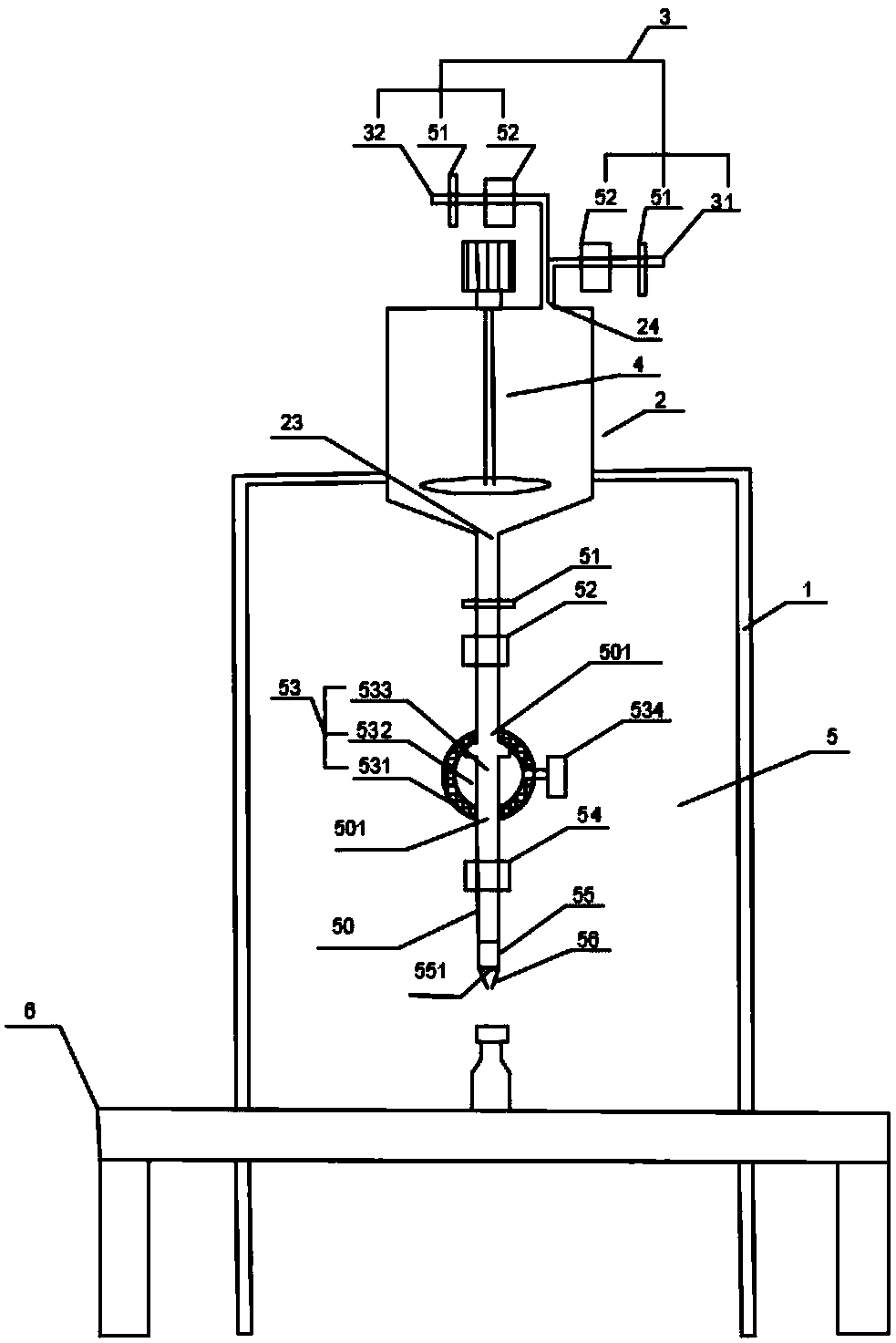

[0032] A kind of emulsion-like skin care product automatic filling equipment described in this embodiment is basically the same as Embodiment 1, and the difference is combined Figure 3 ~ Figure 5 To illustrate, it also includes: the valve sleeve 531 is provided with a control box 534, the control box 534 is provided with a controller 5341, a servo motor 5342, and the surface of the control box 534 is provided with a display screen 5343, buttons 5344 and switches 5345; The servo motor 5342, the display screen 5343, the button 5344, and the switch 5345 are electrically connected; the output shaft of the servo motor 5342 is connected to one end of the spool 532; the feeding device 3 includes a first feeding pipe 31 and a second feeding pipe 32, The first feeding pipe 31 and the second feeding pipe 32 communicate with the cavity of the mixing tank 2 through the general feeding port 24 at the top of the mixing tank 2 .

[0033] The specific implementation process is: open the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com