Three-rotor pulseless volumetric flow meter

A pulsation-free, flowmeter technology, applied in the direction of volume measurement, measurement capacity, volume/mass flow generated by mechanical effects, etc. It can improve the service life and measurement accuracy, increase the stability of the equipment, and achieve the effect of ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

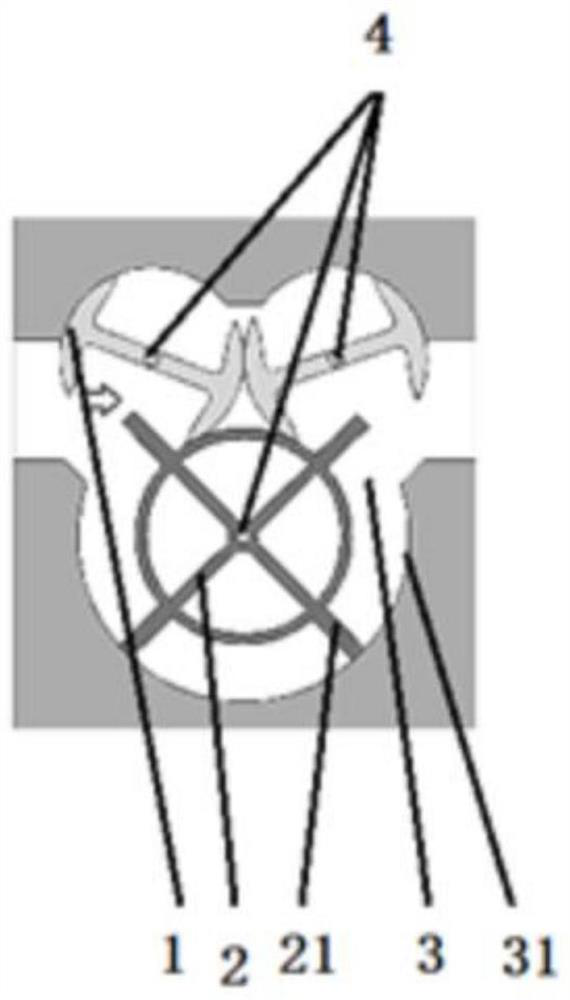

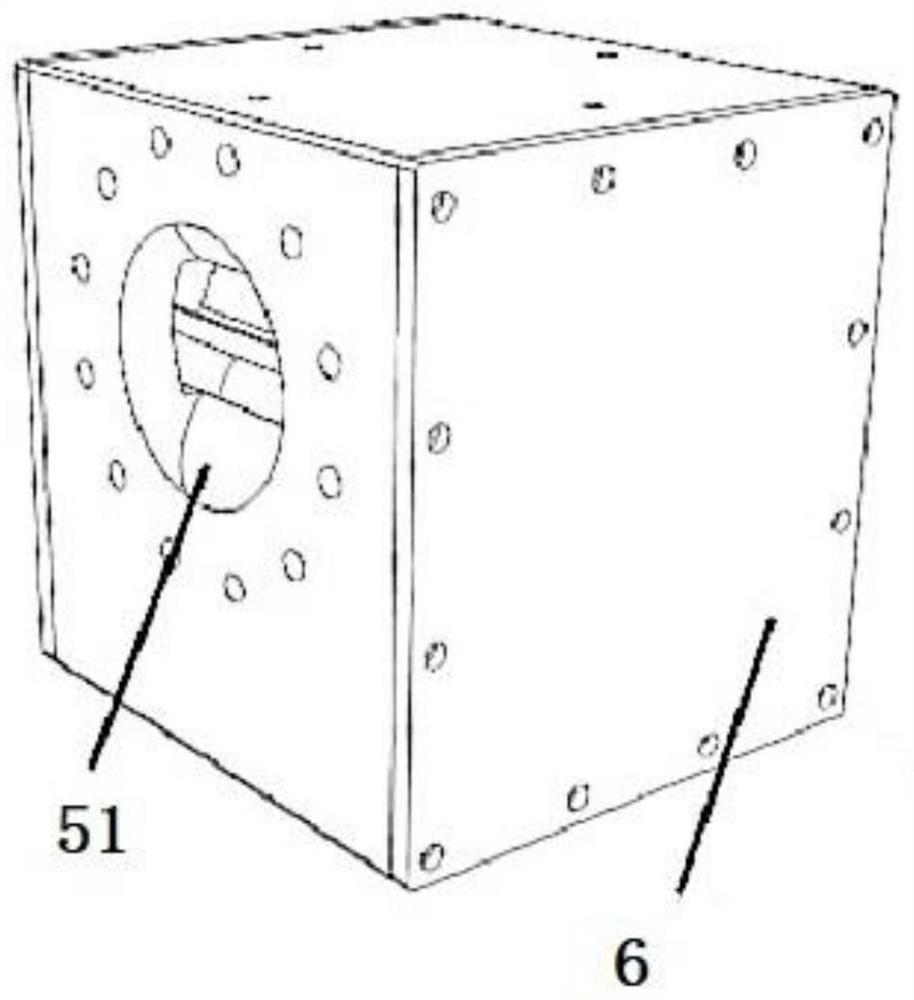

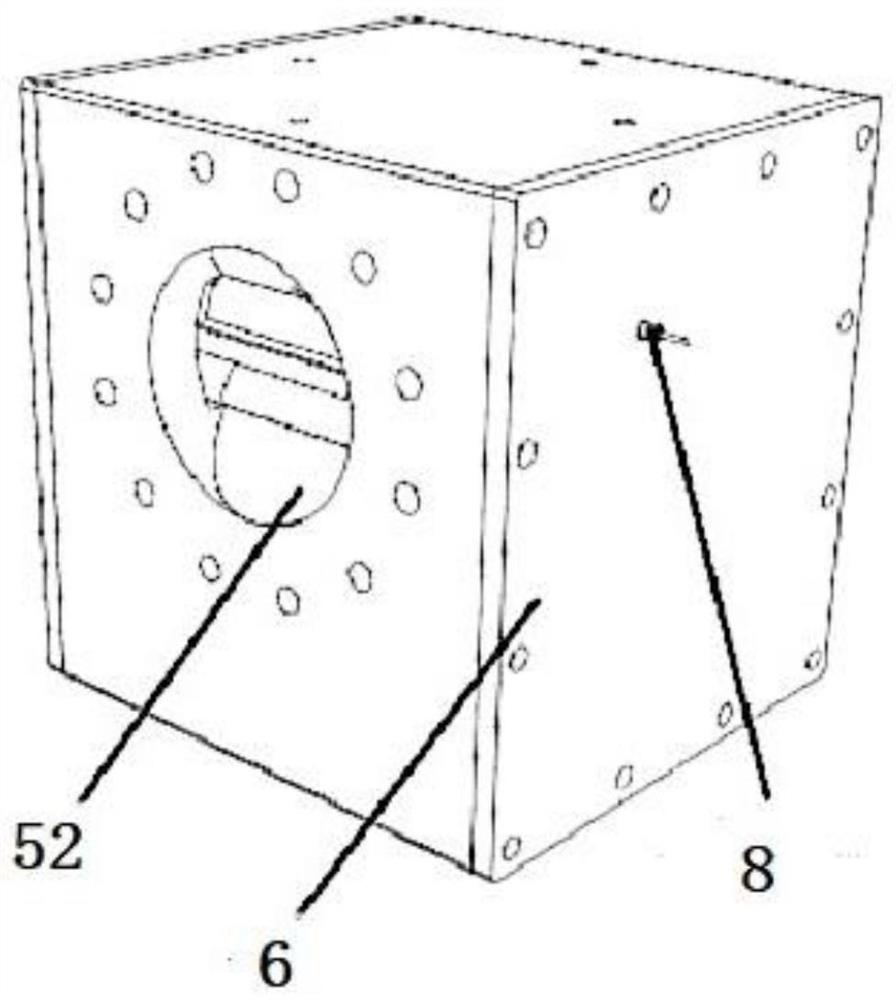

[0031]Such asFigure 1-Figure 3 As shown, the three-rotor non-pulsation type positive displacement flow meter includes a shell and a pulse generator 8 arranged on the shell end cover 6. The pulse generator 8 is also called a proximity frequency sensor or a proximity sensor, including a shell The two metering rotors 1 and one balancing rotor 2 of the internal measurement chamber 3 are both penetrated by the rotating shaft 4. The two ends of the rotating shaft 4 and the inner surface of the front and rear shell end covers 6 are respectively against and fixed, The longitudinal section of the metering rotor 1 is in the shape of an "I" shape, and the track area of its movement is a horizontal cylindrical shape in the measuring chamber 3, and the circular cross sections of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com