Novel turbine volumetric flowmeter with high precision

A flowmeter, high-precision technology, applied in the field of flowmeter, can solve the problems of large pressure loss, troublesome installation and design, high cost, etc., and achieve the effect of small pressure loss, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

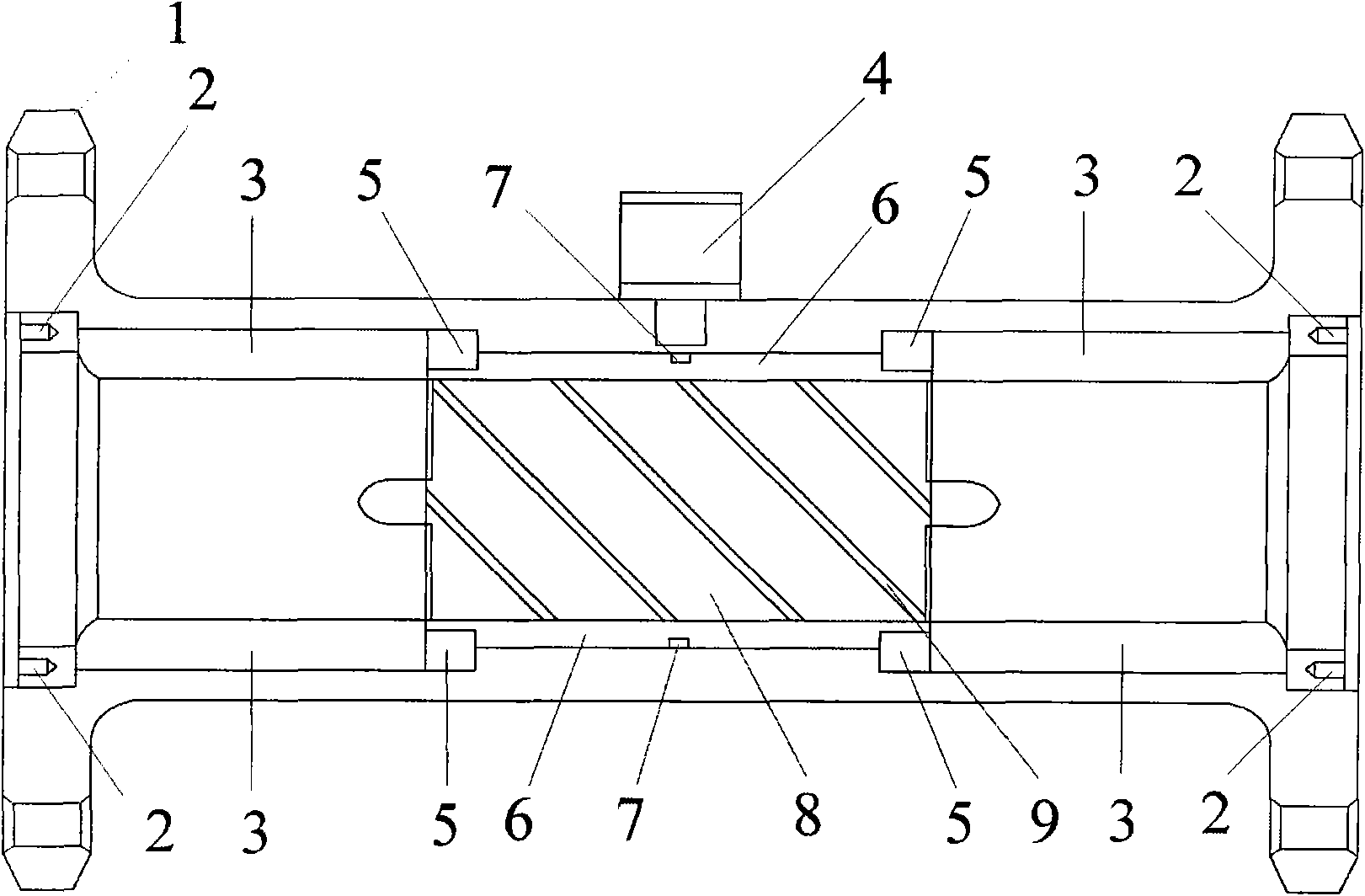

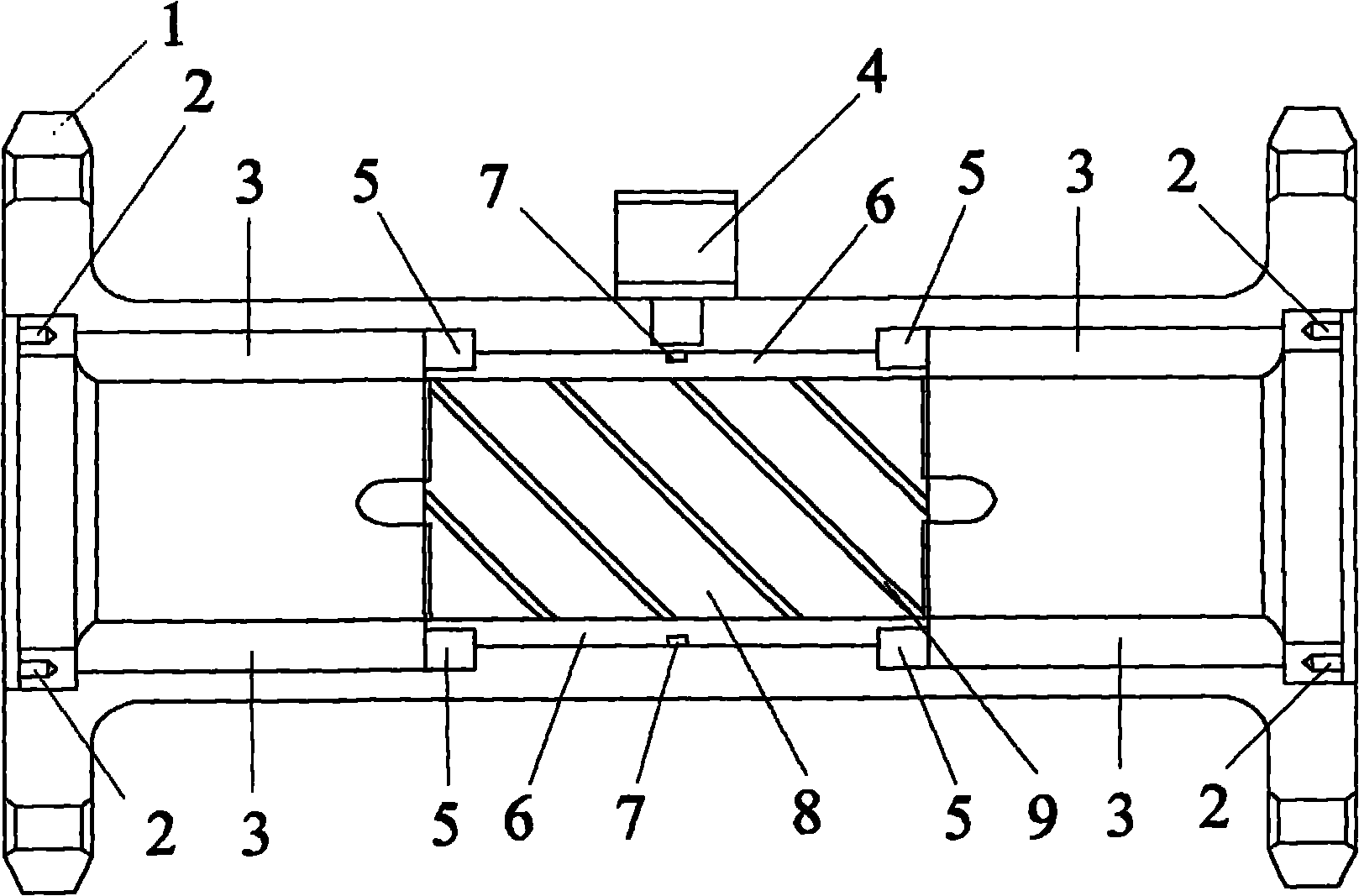

[0024] A new type of high-precision turbine volumetric flowmeter, its structure is as follows figure 1 As shown, the flowmeter includes a housing 1, a lock nut 2, a guide tube 3, a sensor 4, a bearing 5, a turbine rotor body 6, a magnetic steel 7, a large lead deep groove 8 and a large spiral turbine blade 9. The end face of the new high-precision turbine volumetric flowmeter is turbine-shaped and there is no requirement for straight pipe sections before and after installation. The housing 1 is "H"-shaped, and the lock nut 2 connects the guide tube 3 to the housing 1. There are two flow tubes 3, one end of the flow guide tube 3 is connected to the lock nut 2, and the other end is connected to the bearing 5, the sensor 4 is set in the middle of the housing 1, the bearing 5 is set at both ends of the large lead deep groove 8, and the turbine The rotor body 6 is set on the outside of the large lead deep groove 8, the magnetic steel 7 is set on the turbine rotor body 6, the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com