Volume type high order elliptic gear flowmeter

A technology of oval gear and flowmeter, which is applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc. It can solve the problems of less sealing, large pulsation, and increased noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

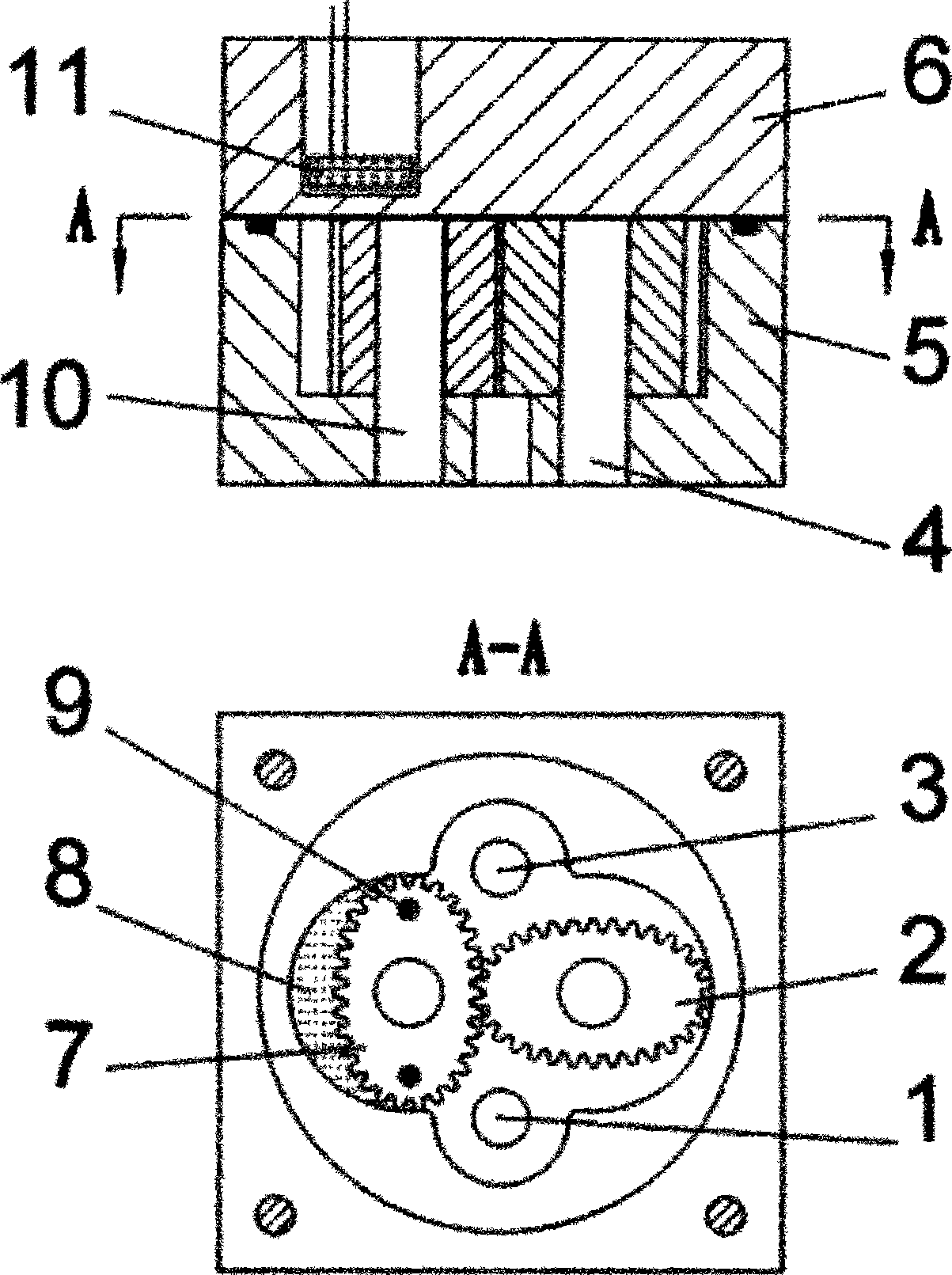

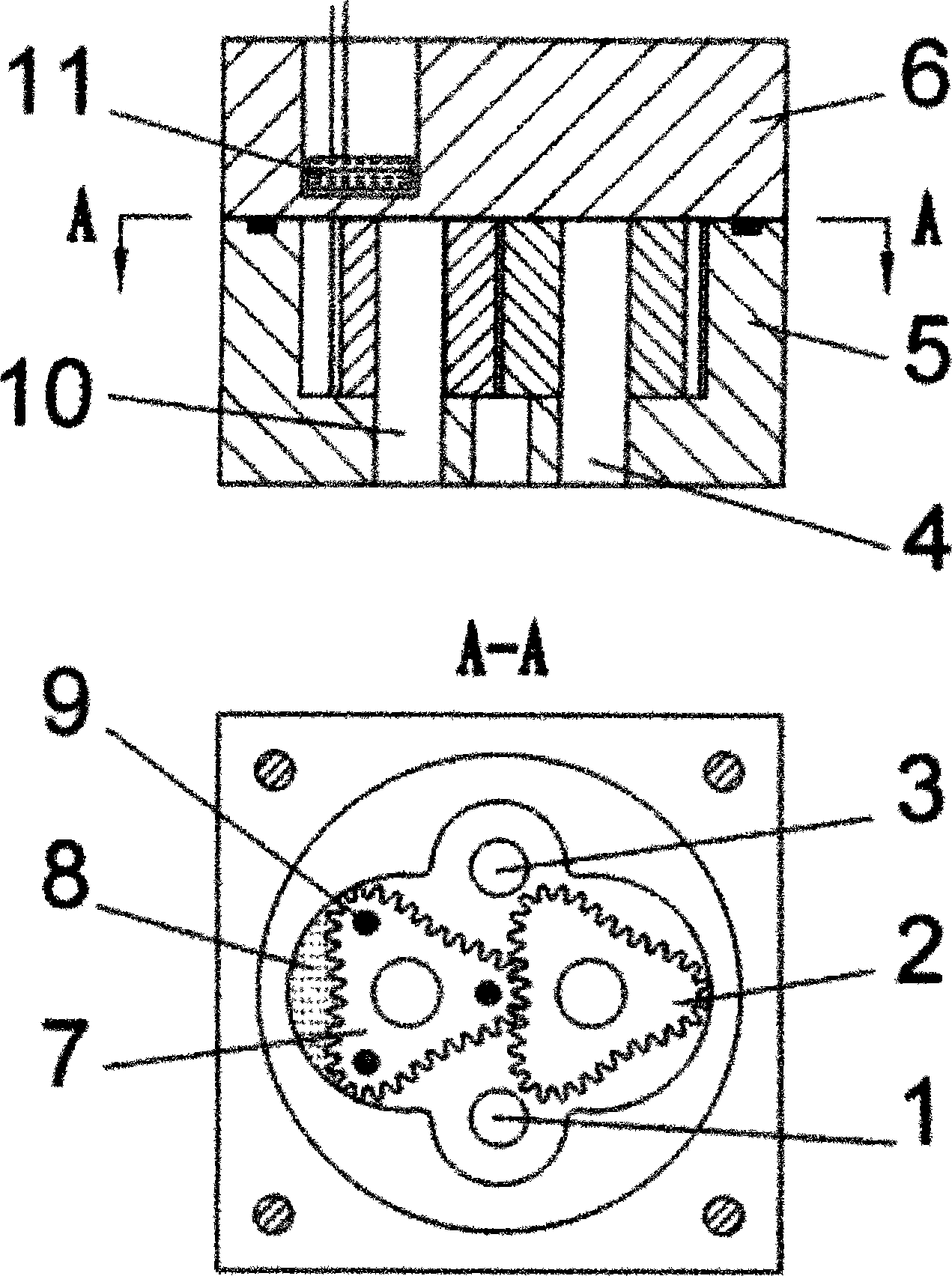

[0013] Such as figure 2 As shown, the high-order oval gear rotor (7) is installed on the shaft (10), the magnetic steel (9) is embedded on the high-order oval gear rotor (7); the high-order oval gear rotor (2) is installed on the shaft (4) Upper: The upper cover plate (6) forms a closed metering space (8) with the high-order oval gear rotor (7) and the housing (5).

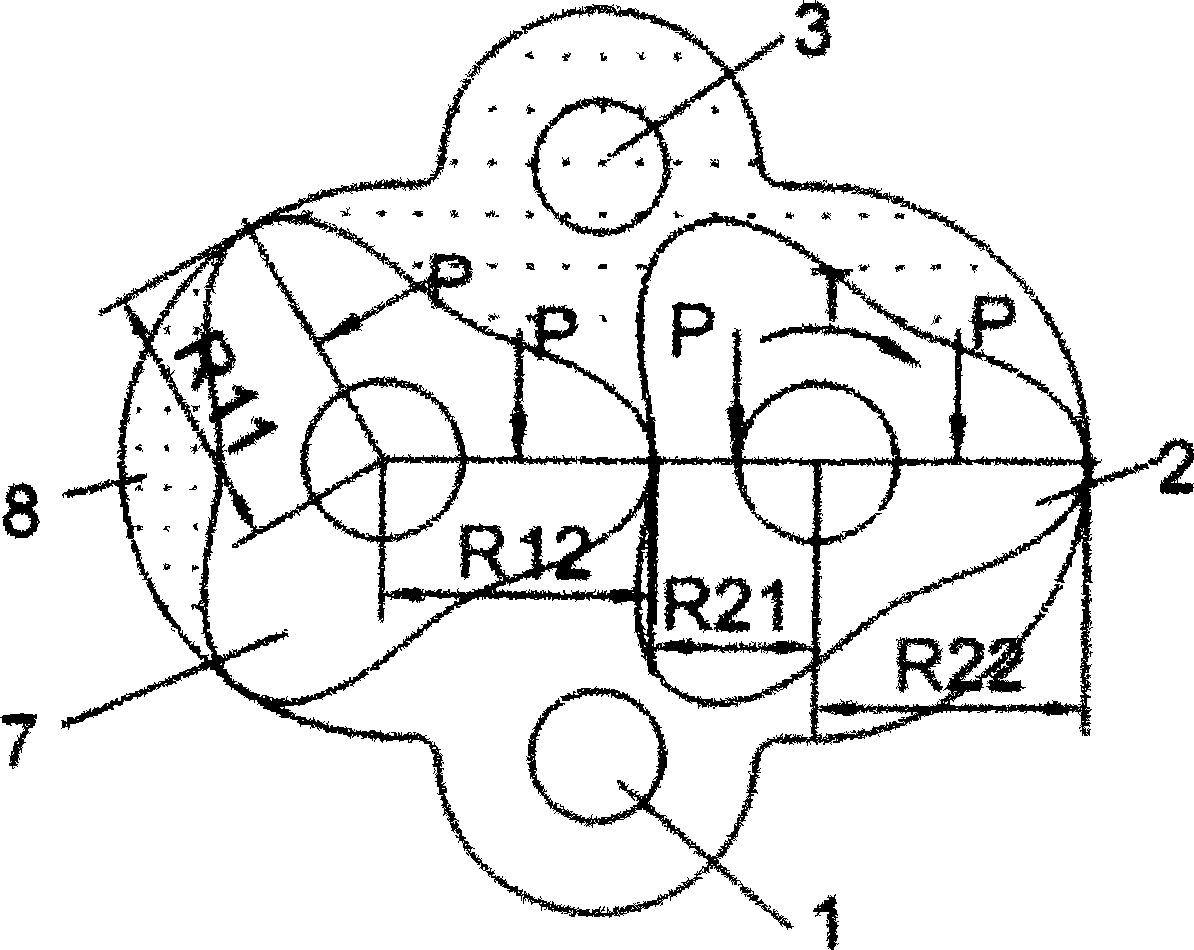

[0014] exist image 3 At the moment shown, the fluid pressure at the inlet (3) is higher than the pressure at the outlet (1), because R11=R12, which means that the torque acting on the high-order oval gear rotor (7) is equal; while R22>R21, the acting The torque T on the high-order elliptical gear rotor (2) is=P*(R22-R21), and P is the pressure of the inlet fluid; at this time, the high-order elliptical gear rotor (2) is the driving wheel, and it rotates clockwise And push the high-order oval gear rotor (7) to rotate counterclockwise, and then discharge the fluid in the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com