Device and method for adding liquid additive

A liquid additive and adding equipment technology, applied in feed, food science, application and other directions, can solve the problems of large fluctuation of adding accuracy, product quality impact, labor waste, etc., to reduce labor costs, accurate and stable adding accuracy, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

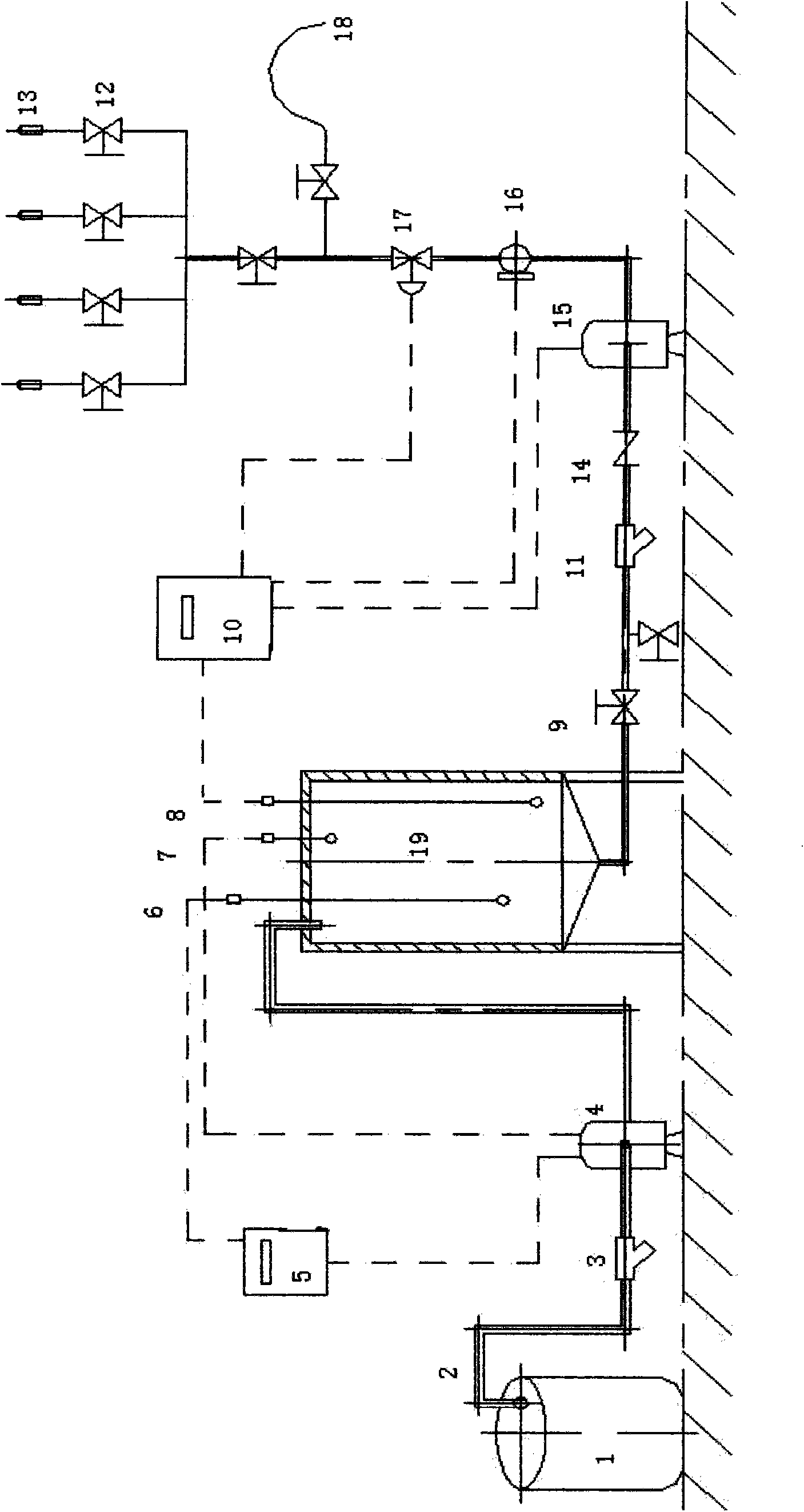

[0033] Such as figure 1 Shown is a structural diagram of the liquid additive adding equipment described in the embodiment of the present invention.

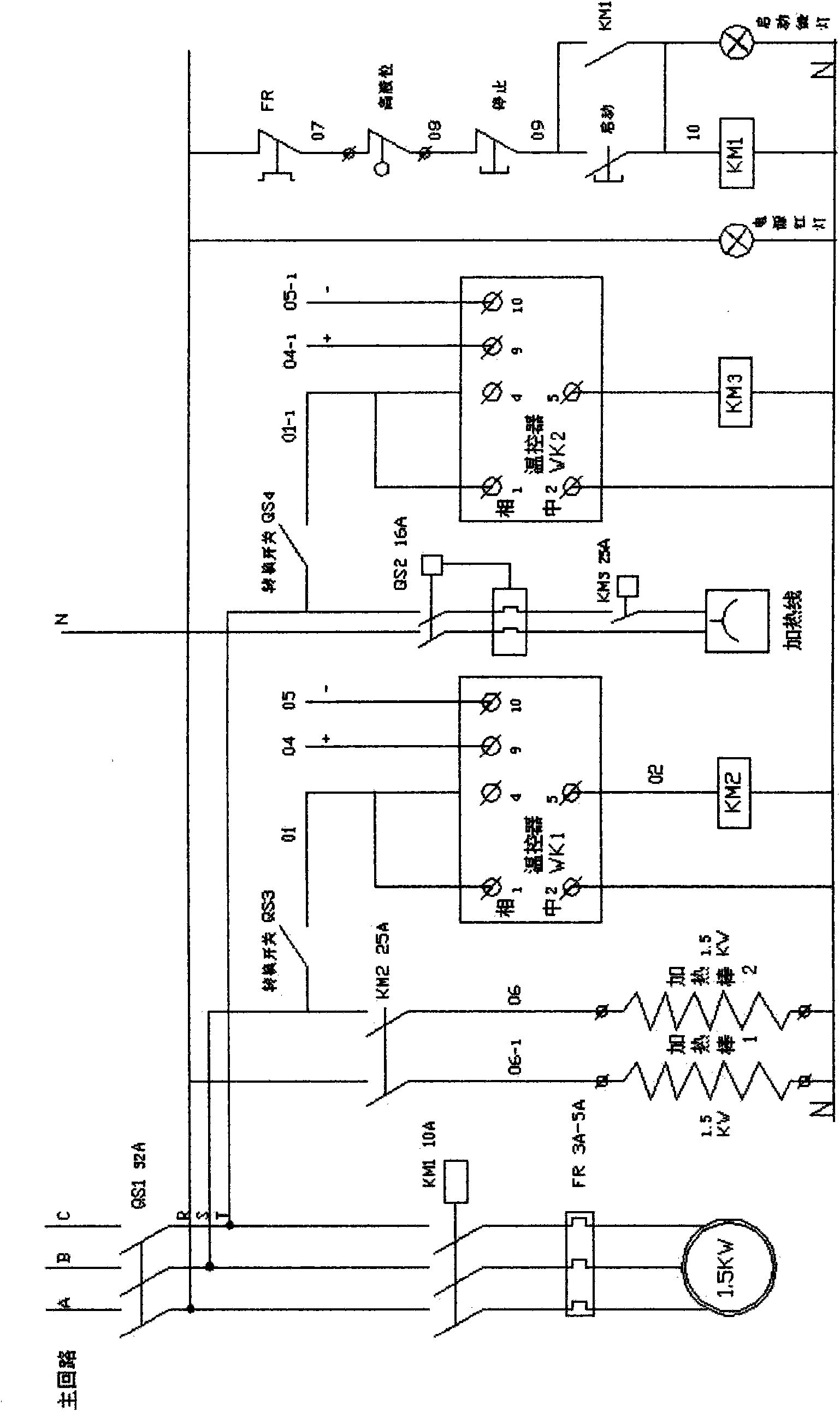

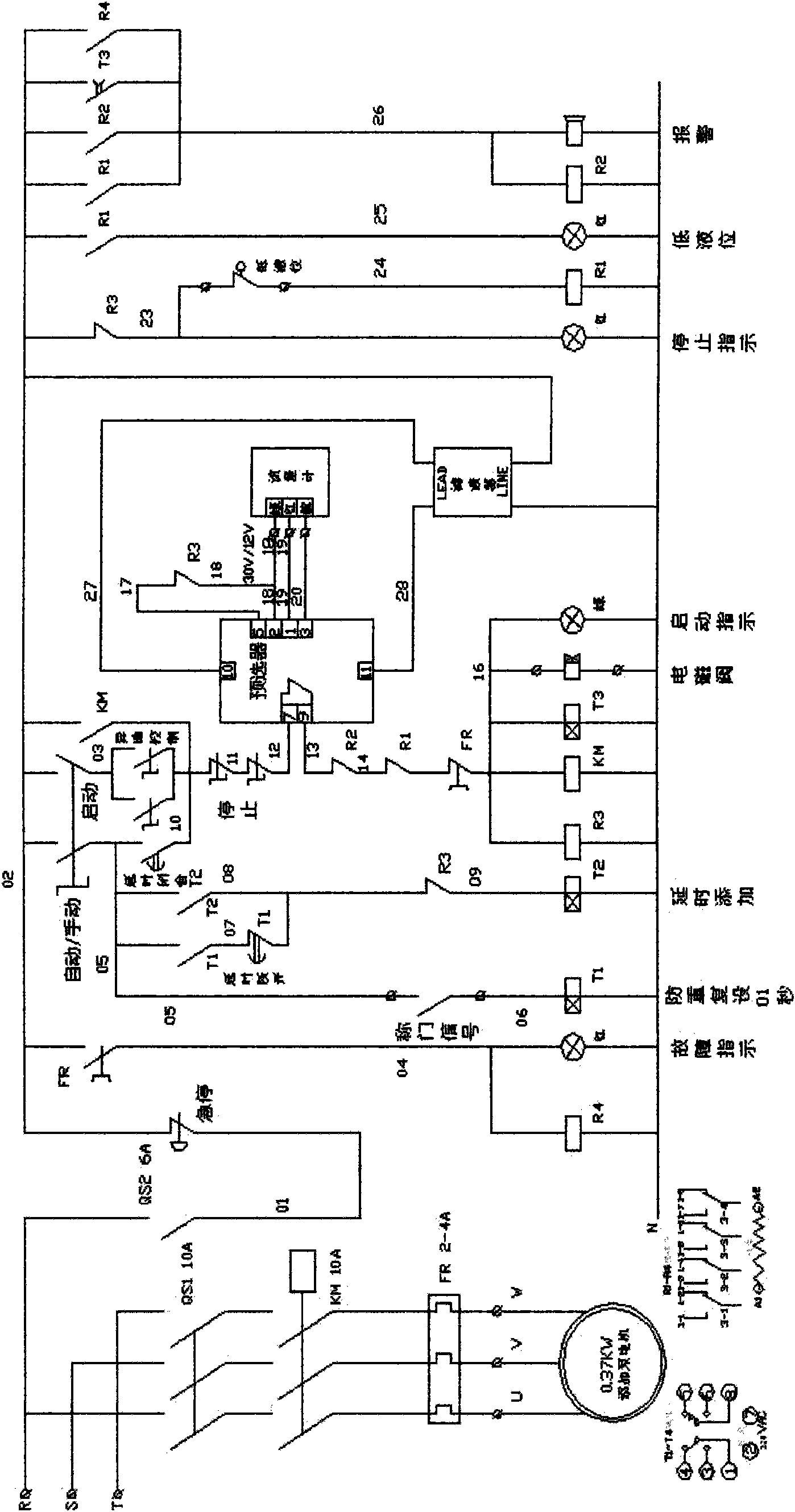

[0034] The various parts of the liquid additive adding equipment of the present invention are respectively: 1. material barrel, 2. connecting pipe, 3. the first filter, 4. input pump, 5. the first control box, 6. temperature controller, 7. high Liquid level device, 8, low liquid level device, 9, ball valve, 10, second control box, 11, second filter, 12, nozzle ball valve, 13, nozzle, 14, one-way valve, 15, adding pump, 16 , flow meter, 17, control valve, 18, test tube, 19, storage tank.

[0035] The liquid is added into the storage tank 19 from the material barrel 1 through the input pump 4, and the state of the liquid in the storage tank 19 is controlled by the high liquid level device 7, the low liquid level device 8, and the temperature controller 6 (the temperature of the liquid is controlled at a certain level all the year ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com