Two-phase flow and dual parameter measurement with bent tube and flowmeter combination and system thereof

A flowmeter and dual-parameter technology, applied in the field of dual-parameter measurement methods and systems, can solve the problems of high instrument cost of imaging content rate analyzer, inapplicability of capacitance analyzer, unsatisfactory use effect, etc., and achieve low cost and system Small pressure loss and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

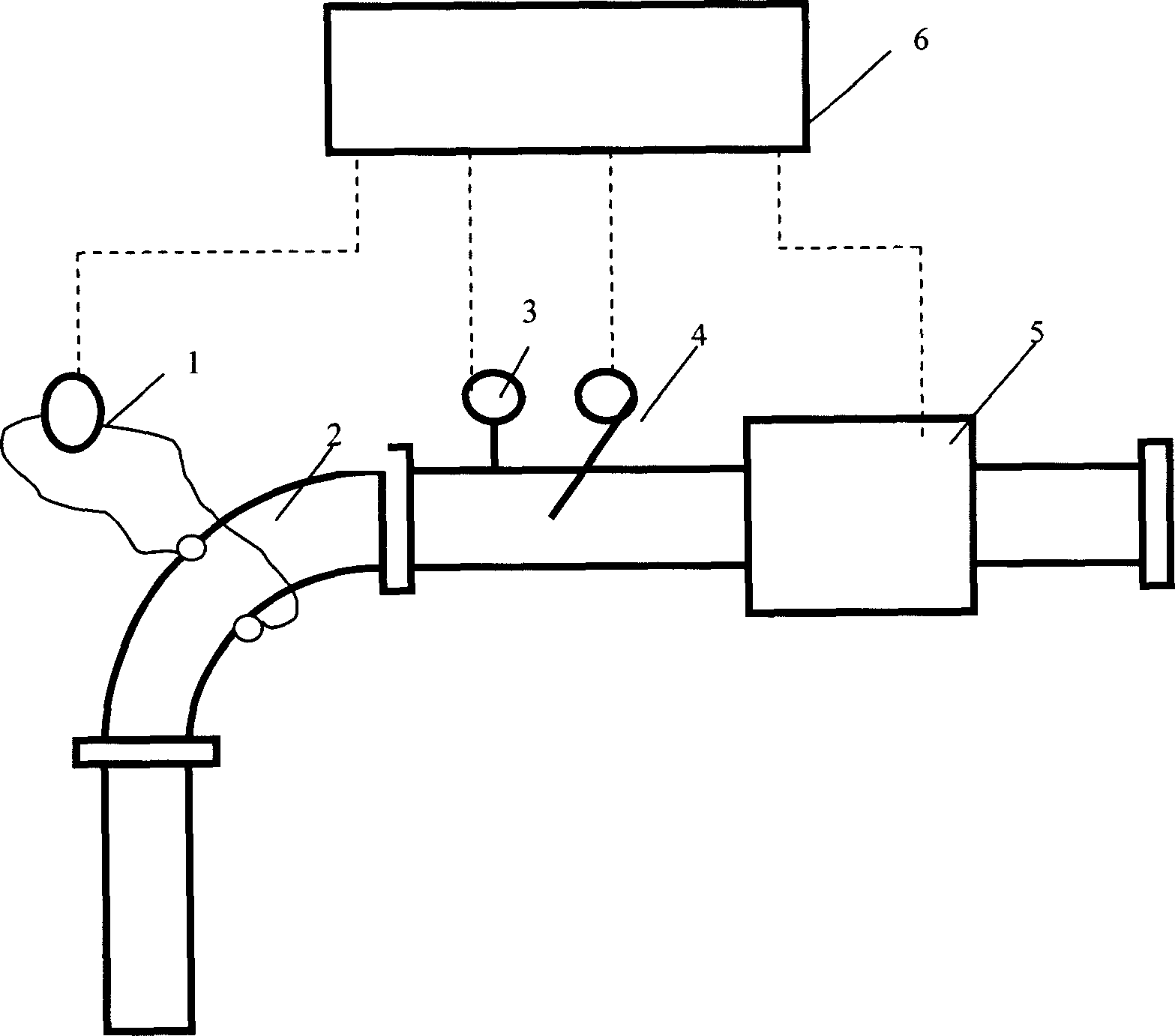

[0008] As shown in the figure, the measurement system includes a differential pressure transmitter 1 , an elbow sensor 2 , a pressure transmitter 3 , a temperature transmitter 4 , a flow meter 5 , and a computer 6 .

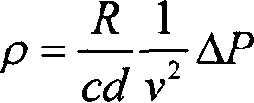

[0009] When the fluid flows through the elbow 2 at a certain flow rate, a pressure difference is generated between the inside and outside of the elbow under the action of centrifugal force, and the differential pressure transmitter 1 detects the differential pressure value of the symmetrical part inside and outside the elbow, and the differential pressure is related to the flow velocity, fluid density, The functional relationship of the elbow structure size parameters is

[0010] ΔP = cρd v 2 R . . . ( 1 )

[0011] In the formula: ΔP-the pressure difference between the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com