Low-pulsation gear flowmeter of composite gear type

A composite gear and flow meter technology, applied in the direction of volume/mass flow generated by mechanical effects, can solve the problems of difficult high-pressure dynamic flow measurement, difficult hydraulic system measurement, and many rotating parts, and achieves simple structure and rotational inertia. Reduced, small flow pulsation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

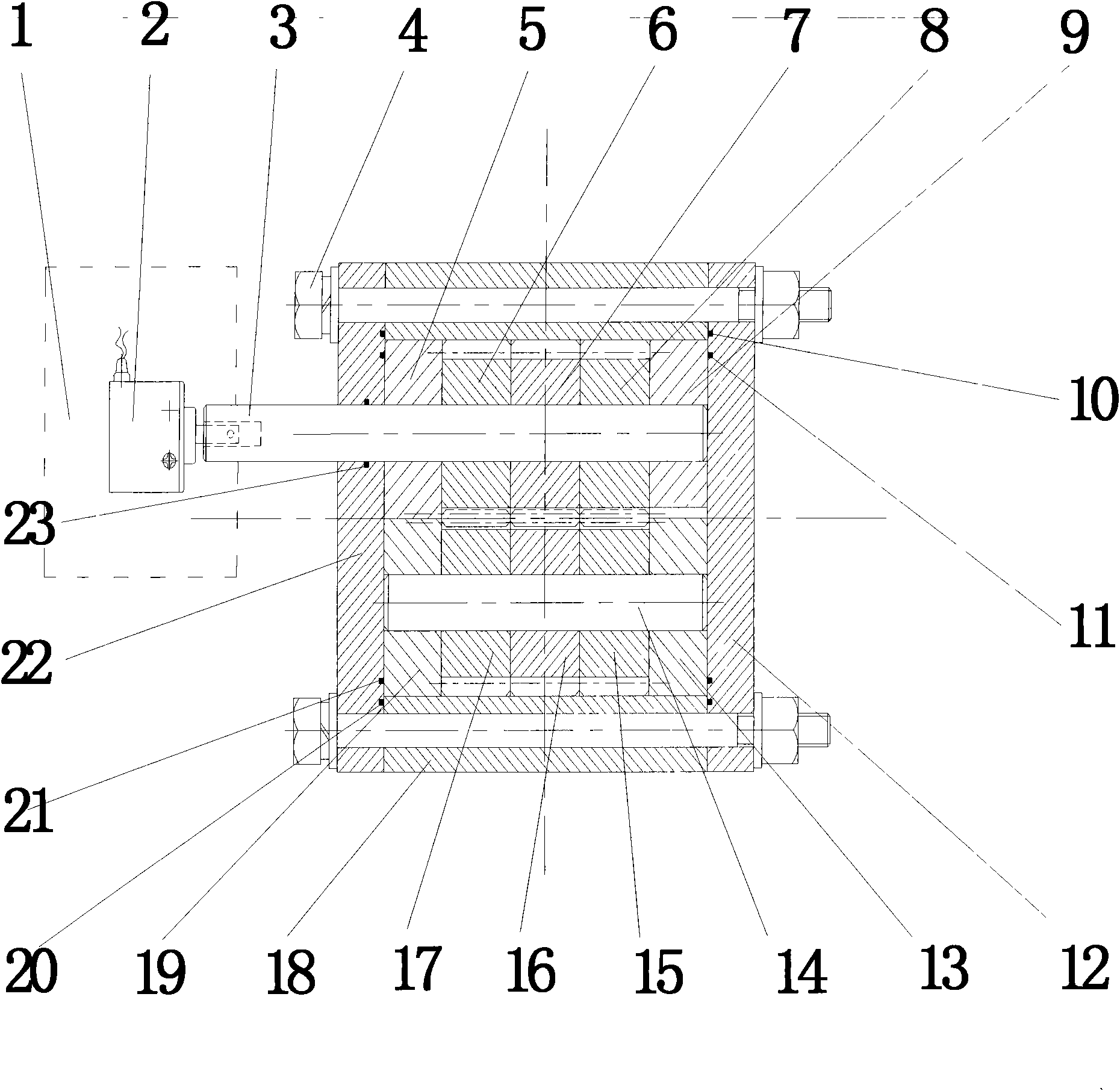

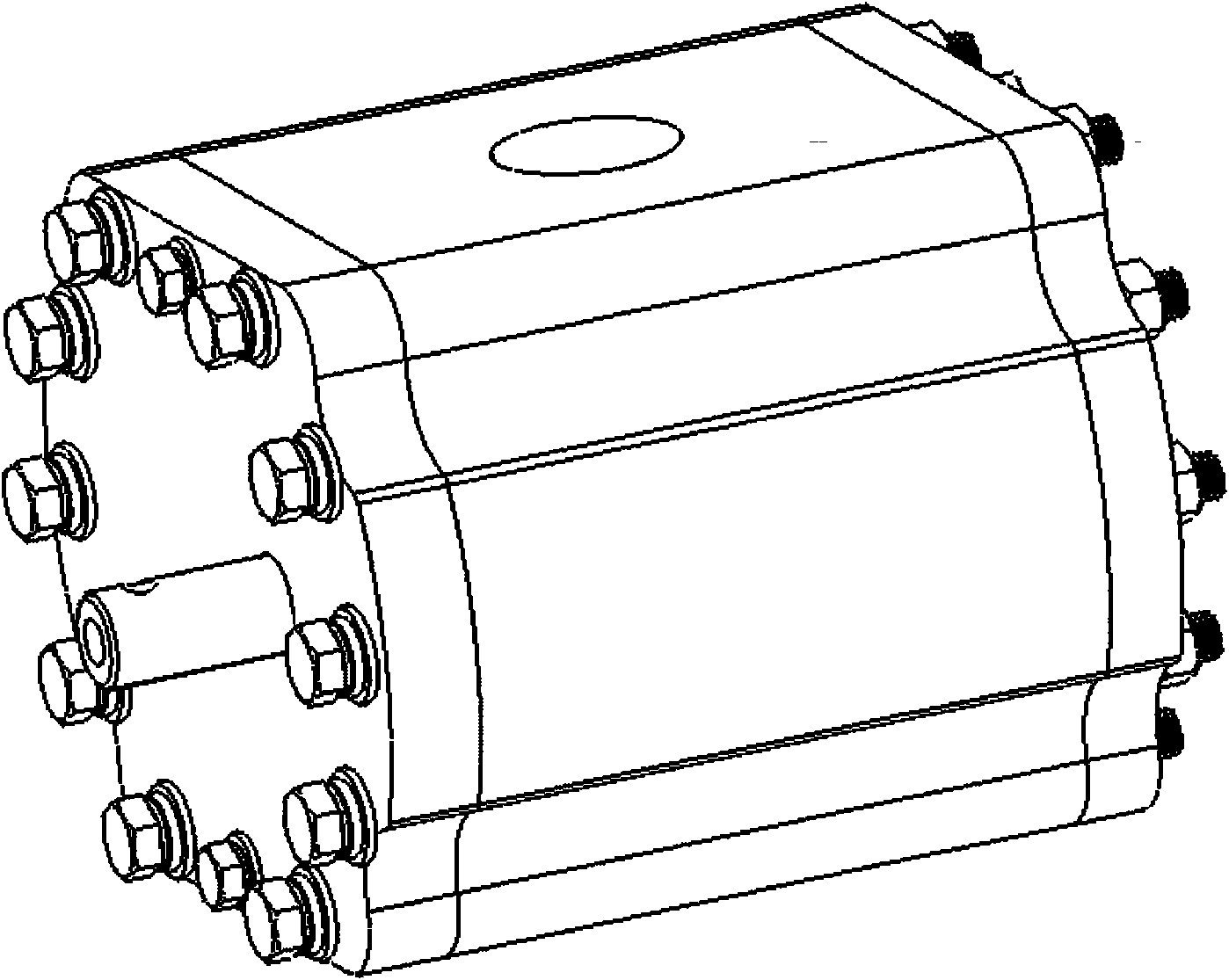

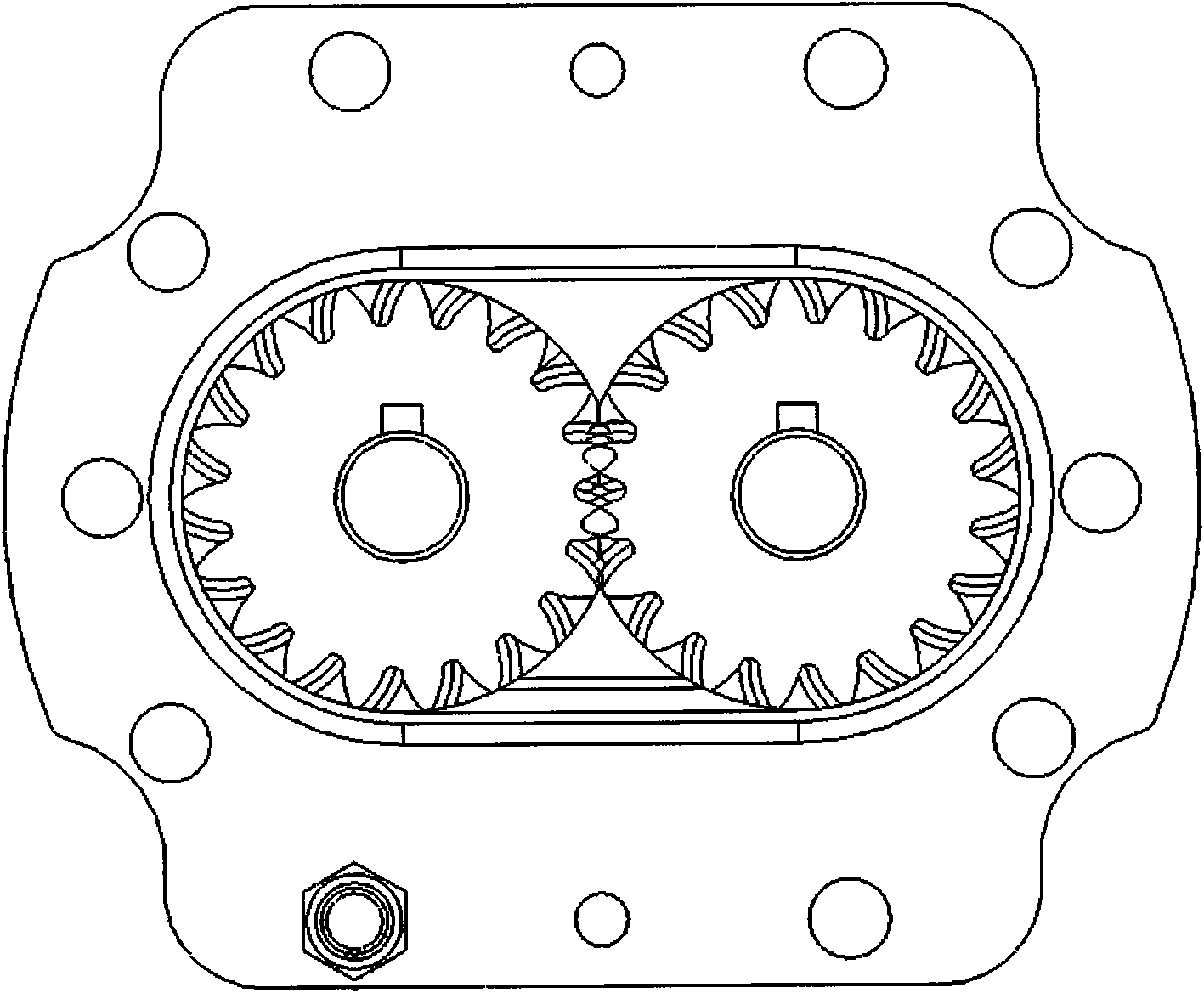

[0016] like figure 1 , 2 , 3, 4 shown, the compound gear that is made up of (6)(7)(8) gear is meshed with the compound gear that is made up of (17)(16)(15), wherein, by (6)(7)( 8) The composite gear composed of three gears is installed sequentially along the axial direction, and 1 / 3 teeth are shifted clockwise in the circumferential direction, while the composite gear composed of (17)(16)(15) is installed sequentially along the axial direction, And in the circumferential direction, they are misaligned by 1 / 3 teeth counterclockwise. The composite gear consisting of (6)(7)(8) gears and the composite gear composed of (17)(16)(15) are supported by shaft 1 (3) and shaft 2 (14) respectively. Rear cover plate (12), front cover plate (22), cylinder block (18) axle sleeve (5), (19), the compound gear that is made up of (6) (7) (8) gear, by (17) ( 16) The composite gear and axle sleeve (9) (13) formed by (15) form an oil inlet chamber and an oil outlet chamber, and an oil inlet and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com