Non round gear and volumetric flowmeter using same

A technology of non-circular gears and flowmeters, which is applied in liquid/fluid solid measurement, measurement flow/mass flow, measurement devices, etc., and can solve the problems of undurable, short-sealed gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

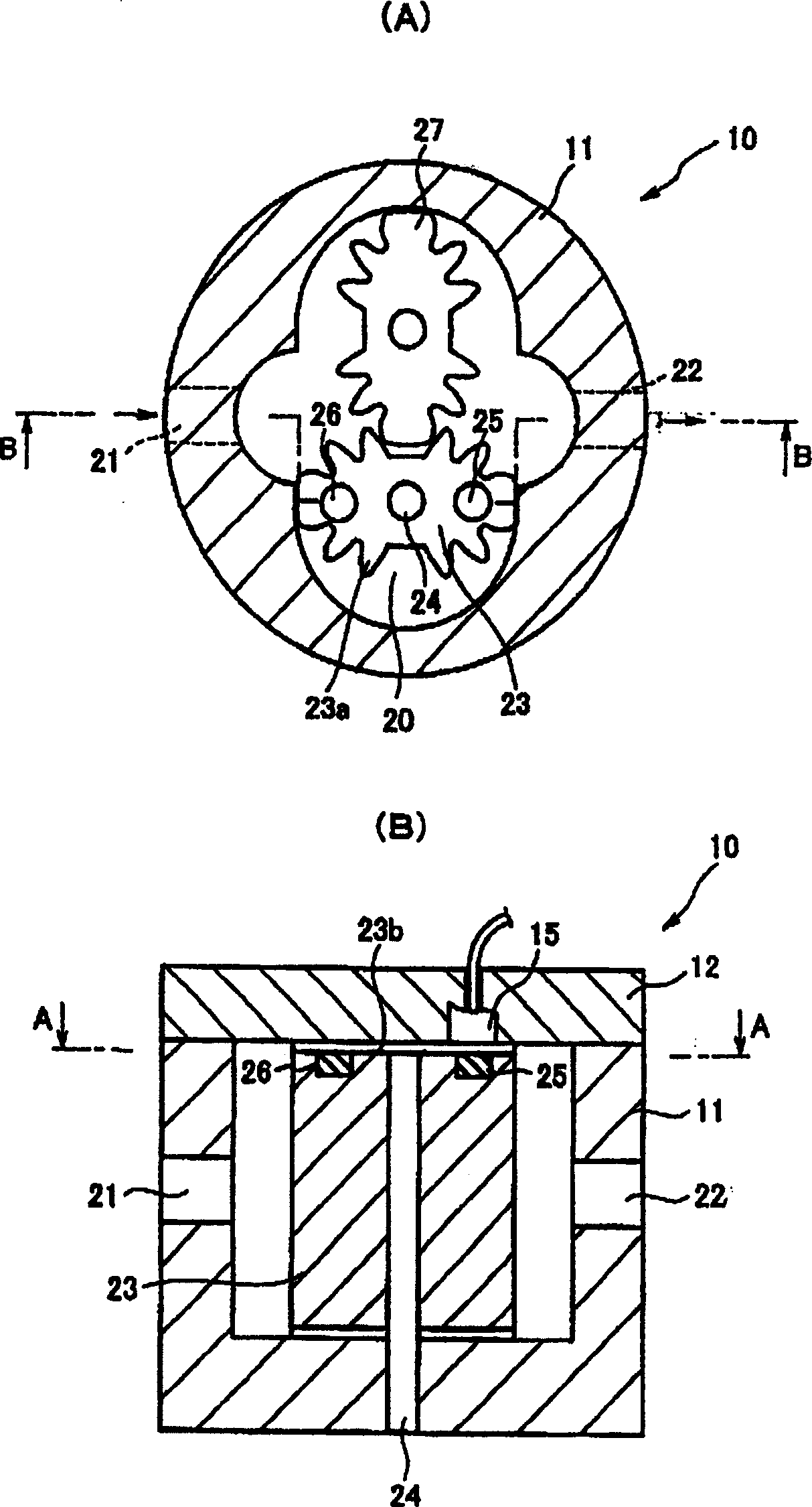

[0033] figure 1 It is a diagram showing a configuration example of a positive displacement flowmeter having a non-circular gear according to an embodiment of the present invention, figure 1 (A) is figure 1 (B) A-A line view sectional view, figure 1 (B) is figure 1 (A) B-B line view section view. In the figure, symbol 10 is a positive displacement flowmeter, symbol 11 is a casing (outer basket), symbol 12 is an end plate, symbol 15 is a magnetic sensor, symbol 20 is a measuring chamber, symbol 21 is an inlet, and symbol 22 is an outlet. , Symbols 23 and 27 are rotors, symbol 23a is the gear part (engagement part) of the rotor 23, symbol 23b is the end surface of the rotor 23, symbol 24 is the rotating shaft of the rotor 23, and symbols 25 and 26 are magnets.

[0034] The main components of the positive displacement flowmeter 10 are: the outer basket 11, the cover (end panel) 12, and the measuring chamber 20 corresponding to the space formed by the outer basket 11 and the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com