Servo type volumetric flowmeter

A flowmeter and volumetric technology, applied in the field of servo-type volumetric flowmeters, can solve problems such as increased instrument error density and fluid leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

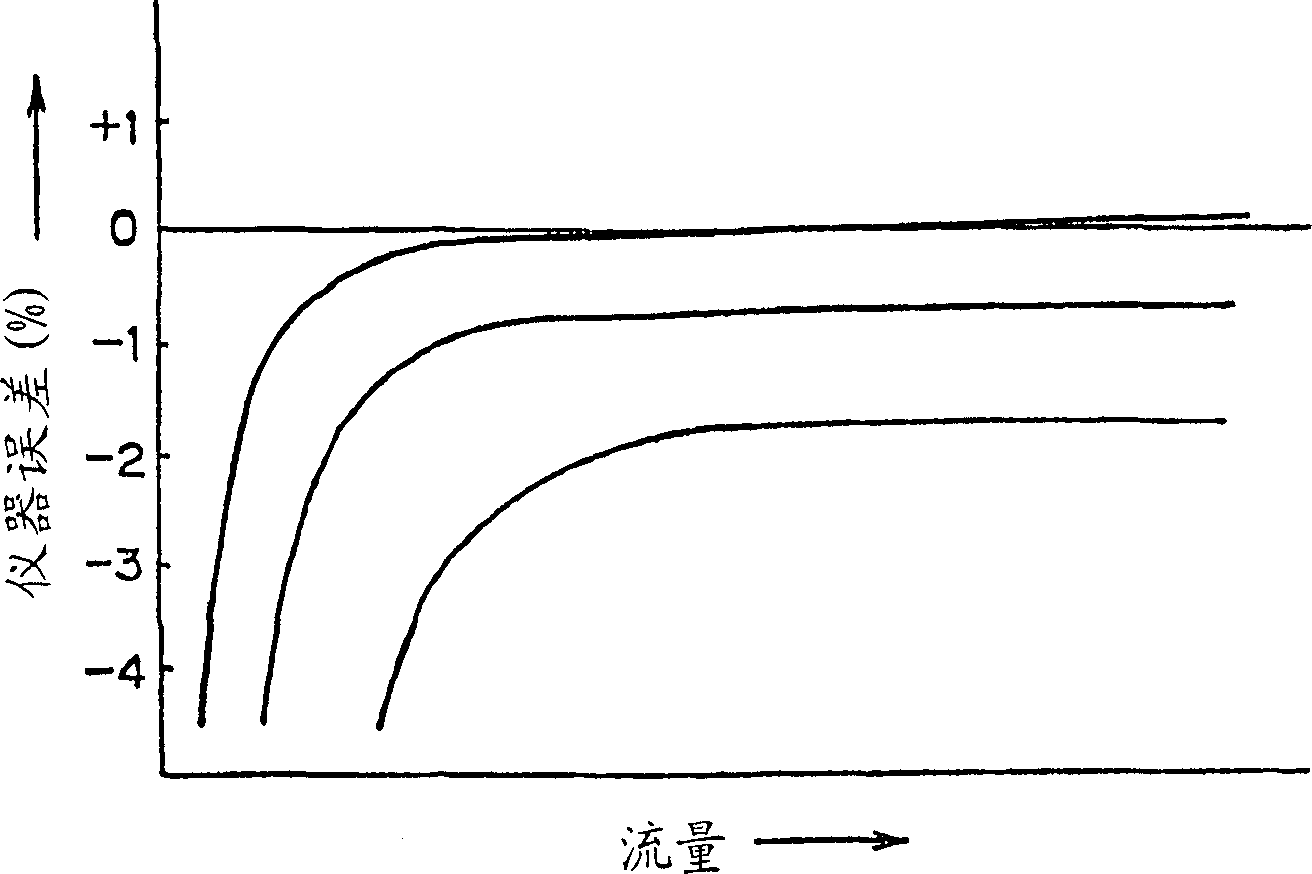

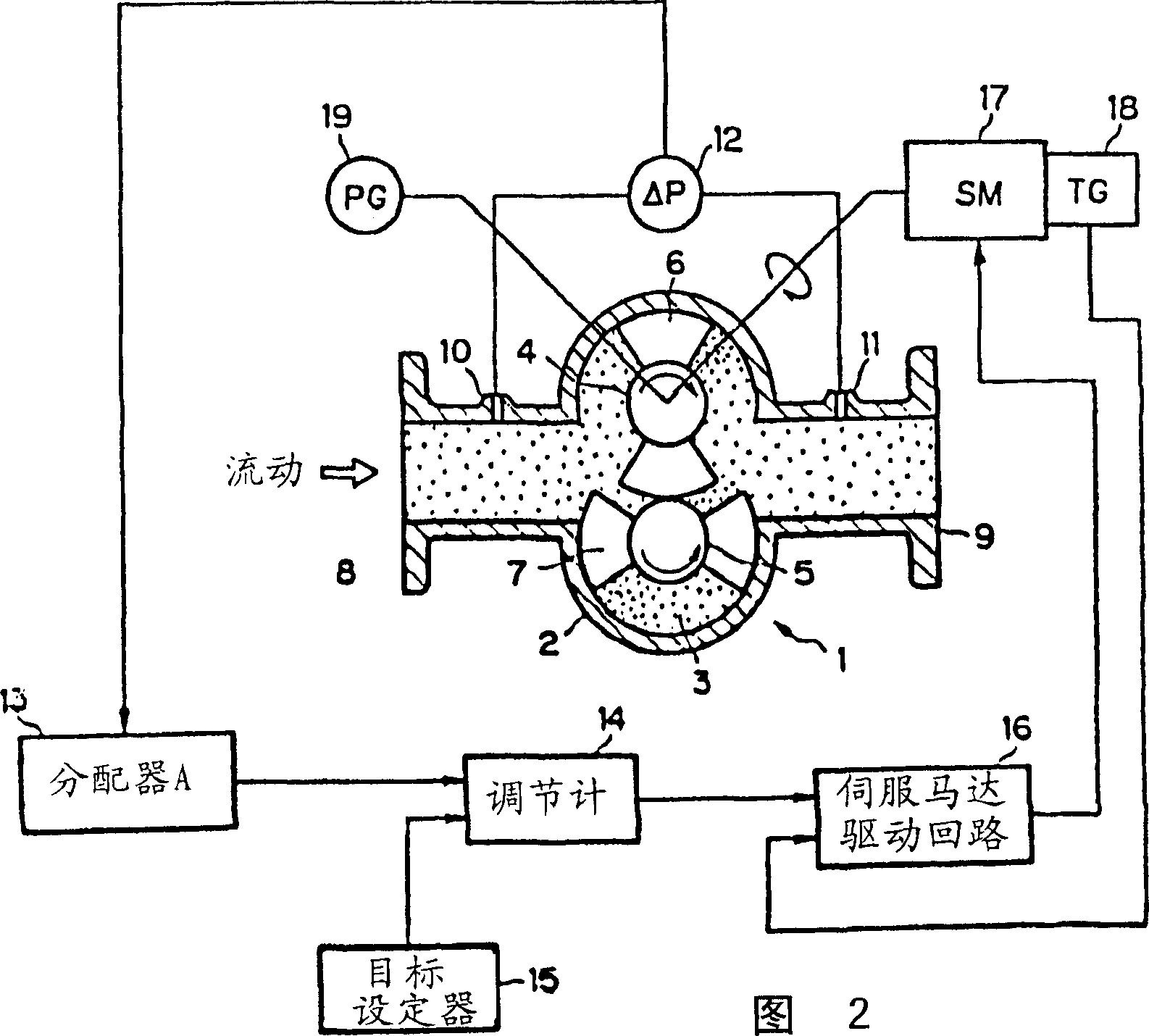

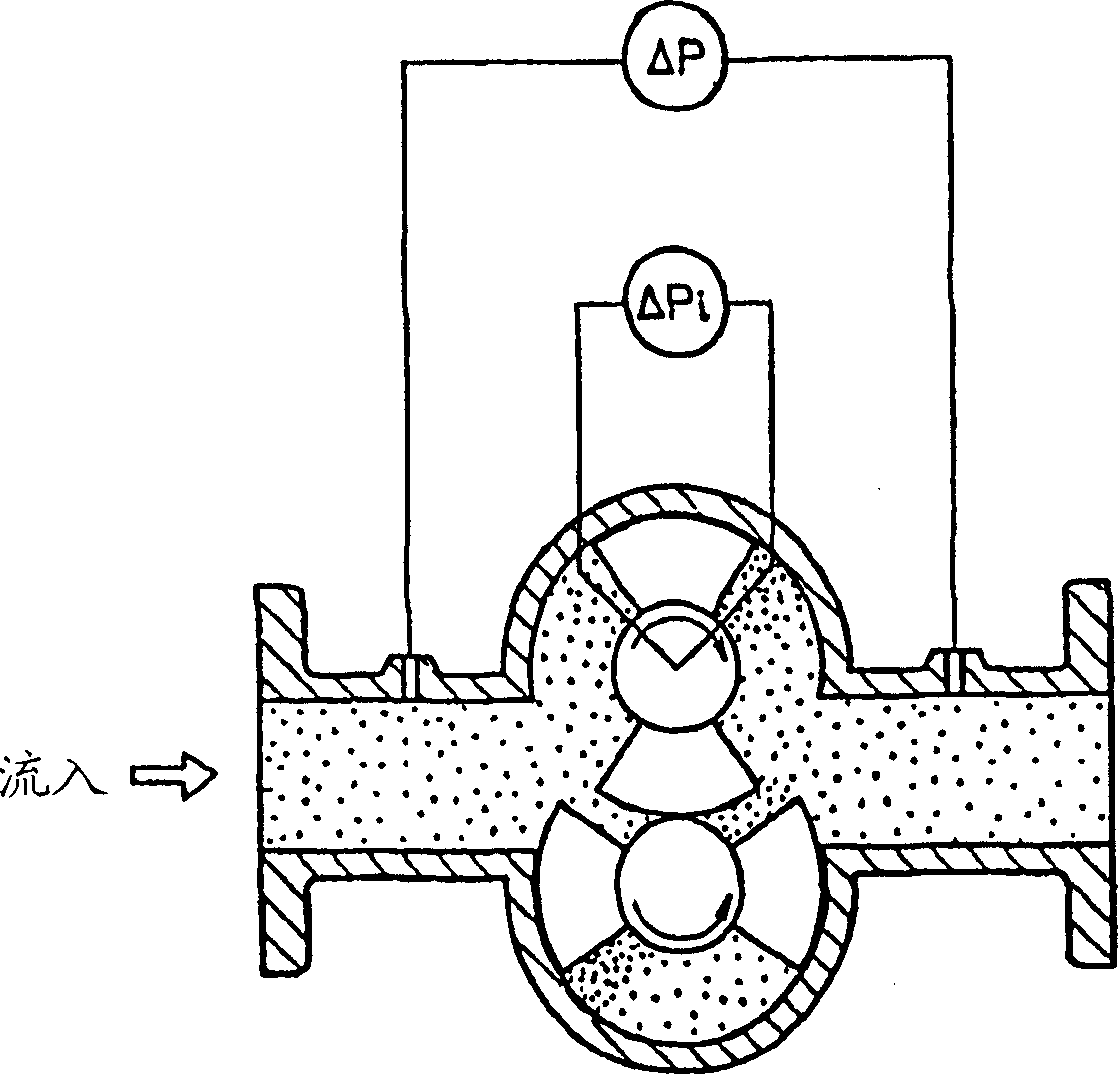

[0036] Generally, when the fluid flows through the positive displacement flowmeter, when a pressure loss of ΔP occurs at the pressure difference detection position sufficiently away from the rotor, the formula

[0037] ΔP=ΔP1+ΔP2

[0038] established. Here, ΔP1 is the pressure loss required to rotate the rotor. Since it is directly related to the leakage inside the flowmeter, it is called the internal pressure loss. In addition, ΔP2 is the pressure loss consumed by the fluid flowing through the flowmeter. Since it is not directly related to leakage, it is called external pressure loss.

[0039] In a positive displacement flowmeter with a pair of built-in rotors, relative to the pressure difference ΔPi before and after the rotor related to the leakage inside the flowmeter, the leakage inside the flowmeter per unit time is Δq, when the viscosity of the fluid is μ, the flow rate is When Q is expressed by the following formula,

[0040] Δq=ka·(ΔPi / μ)+kb·Q...(1)

[0041] Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com