Method for producing absolute zero-position alignment marks by semi-reflective zero-position grating

A zero grating and alignment mark technology, applied in the field of measurement and metrology, can solve the problem that the transmission zero grating cannot be applied to the equipment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Generating an absolute zero alignment mark through a transflective zero grating

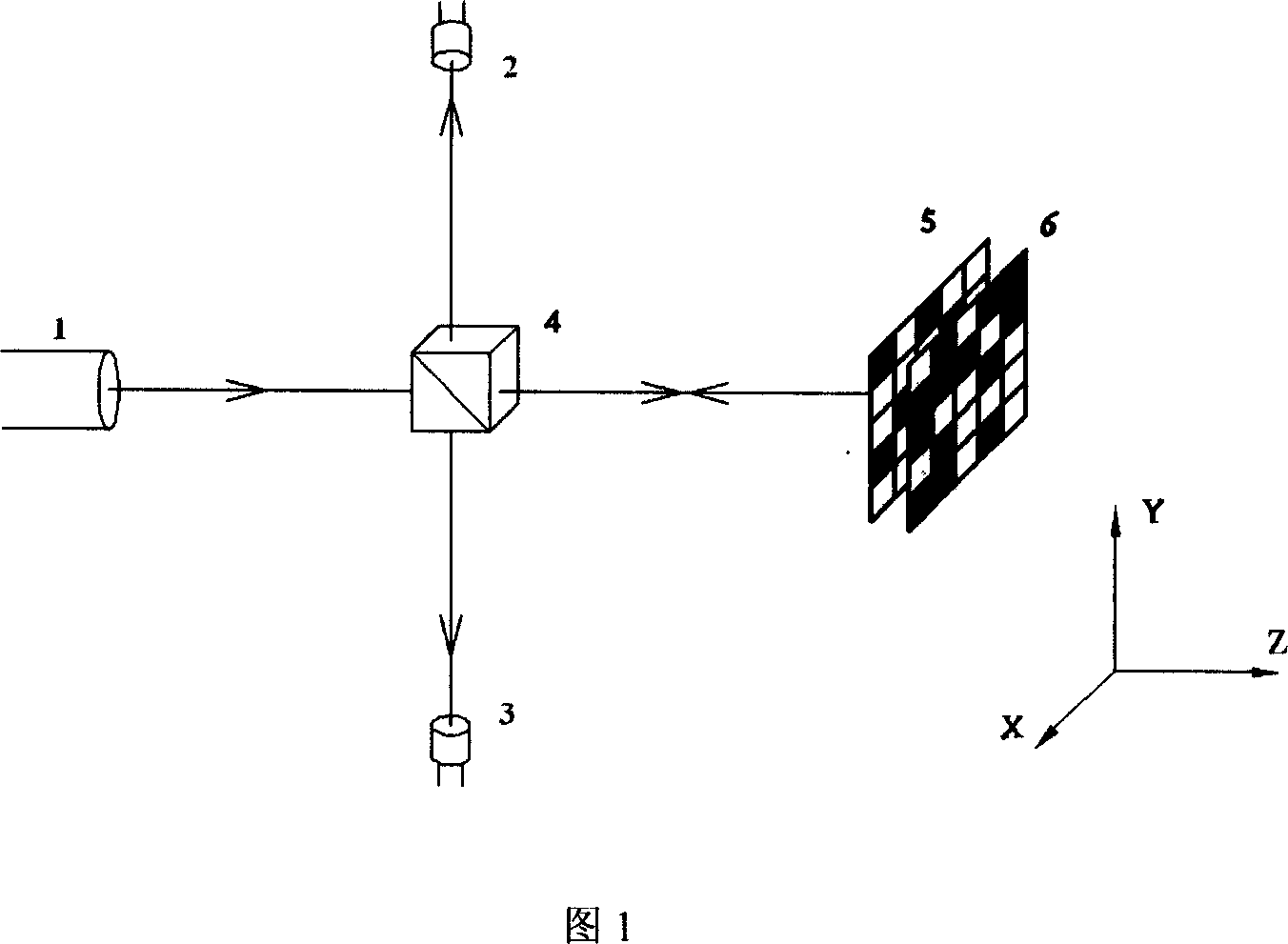

[0019] Figure 1 shows a schematic diagram of the structure of a transflective two-dimensional zero grating system: the coordinates Y and Z are perpendicular to each other. The parallel light source 1 passes through the beam-splitting prism 4 vertically, and the working surface of the beam-splitting prism 4 is parallel to the X-Y plane. After beam-splitting, the first optical axis passes through the beam-splitting prism 4 and propagates along the Z direction, and the second optical axis passes through the beam-splitting prism 4 The reflection propagates along the negative direction of the coordinate Y; a photoelectric receiver 3 is placed on the second optical axis, which is used to judge the intensity change of the light source and compensate the final result; the transmission grating 5 is installed behind the beam splitting prism 4, and the first The optical axis is perpendicul...

Embodiment 2

[0025] Example 2: Application of transflective alignment technology in photolithography machine

[0026] The transflective method can be used as a lithography alignment technology for the alignment of the mask and the silicon wafer in the lithography machine.

[0027] Select the grating with the corresponding grid constant according to the alignment accuracy requirements, make the transmission grating on the mask, and make the reflective grating on the silicon wafer. To align the mask with the silicon wafer in the lithography machine, the mask must be aligned. Combine with the silicon chip as follows: first place the mask perpendicular to the incident light path, then install the silicon chip on a plane parallel to the plane where the mask is located, and perpendicular to the incident light path; adjust the relative position of the mask and the silicon chip so that The two gratings made on them are completely aligned, and then the distance between the two is adjusted to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com