Method and device for measuring refractive index of rear spectrophotometric pupil laser differential confocal lens

A technology of differential confocal and measurement methods, which is applied in the directions of measuring devices, phase influence characteristic measurement, and material analysis, etc., which can solve problems such as system structure, complex assembly and adjustment process, and large errors, so as to reduce the impact and reduce measurement errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

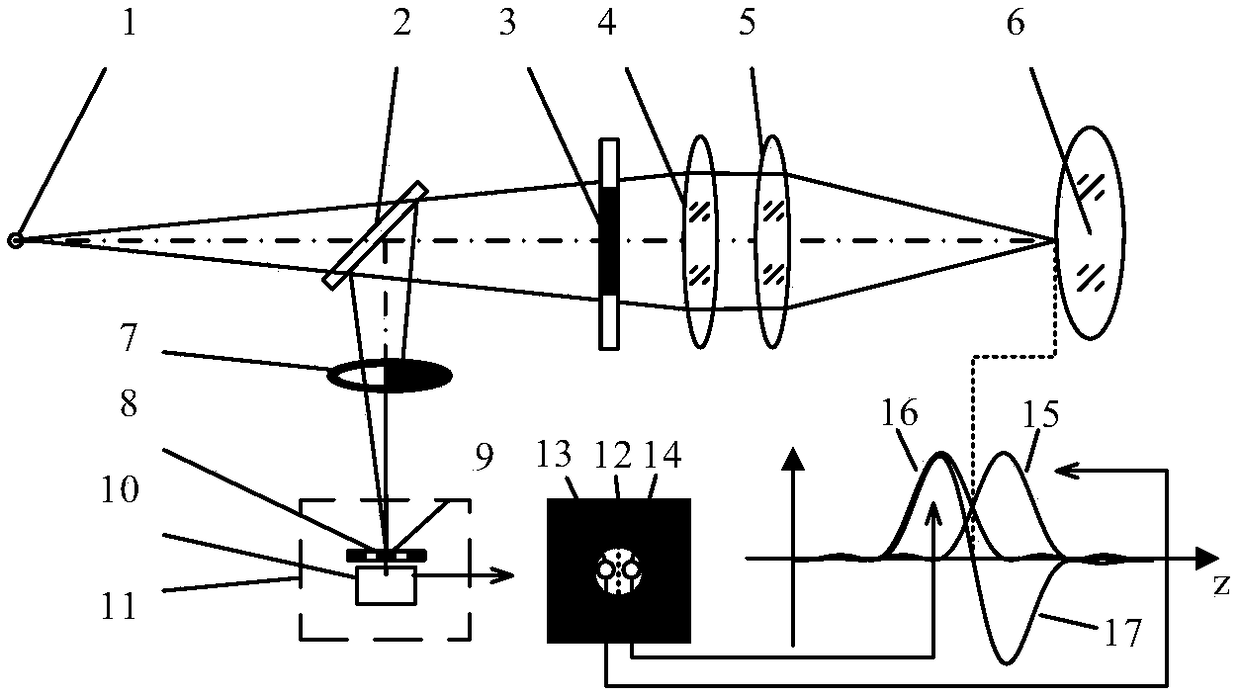

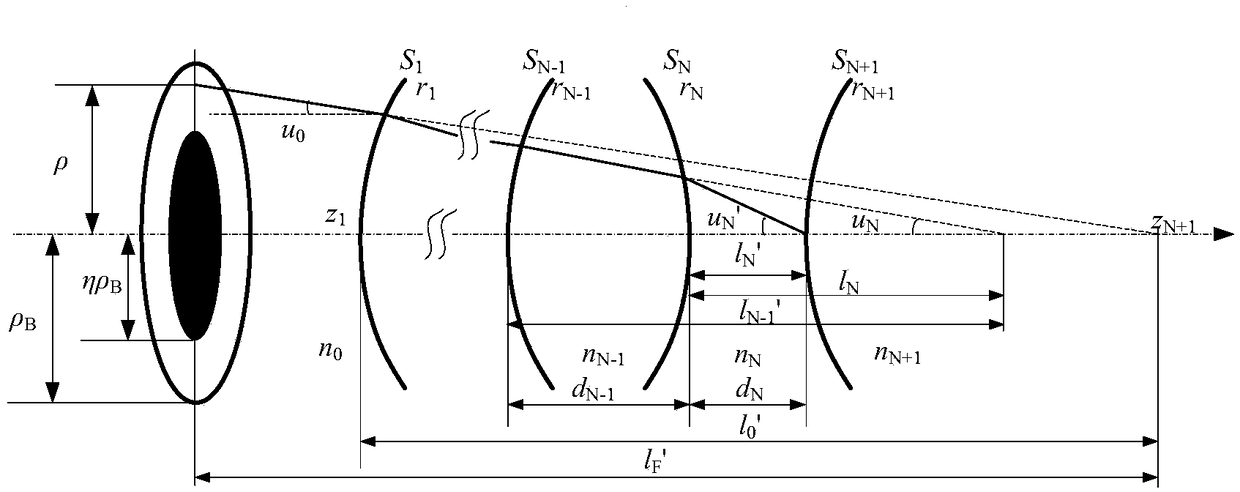

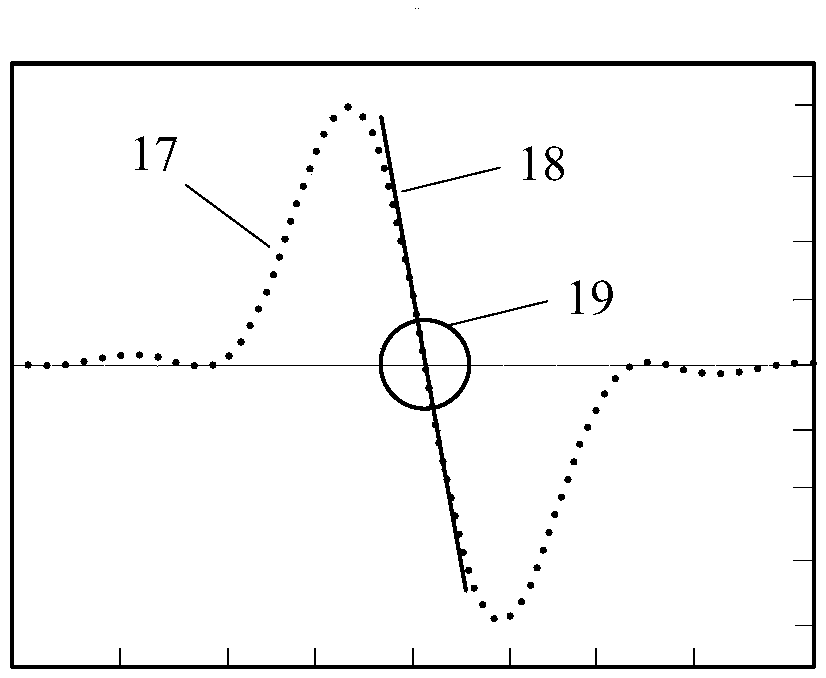

[0047] Such as Figure 4 As shown, the post-pupil laser differential confocal lens refractive index measurement device includes a laser 22, an optical fiber 23 and a point light source 1, which are sequentially placed in the beam splitter 2, collimating lens 4 and converging The lens 5 also includes a D-shaped rear pupil 7 placed in the reflection direction of the beam splitter 2 and a split-pupil differential confocal detection system 11 composed of a microscope objective lens 20 and a CCD 21; a main control computer 24 and a motor drive system 25 connected so that it drives the lens under test 6 to scan along the optical axis on the linear guide rail 26 .

[0048] When using the device to measure the refractive index of the lens, use the split-pupil differential confocal detection system 11 in the system to locate the vertex position of the front surface and the vertex position of the rear surface of the measured lens 6 with high precision, and then measure its refractive in...

Embodiment 2

[0059] The measurement steps in this embodiment are the same as in Embodiment 1, as Figure 5 Shown is the center measurement device diagram of the rear split-pupil laser differential confocal lens in this embodiment, Figure 4 The D-type rear pupil 7 in is replaced by the circular rear pupil 30 here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com