Dynamic compensation method of attemperation water impact leading steam temperature measuring point in boiler steam temperature control system

A technology of steam temperature control and dynamic compensation, applied in the field of boilers, can solve the problems of large object inertia and delay in the inert zone, affecting the control quality of the system, and instability of the control system, so as to improve the control quality, safety and economy, Easy to debug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

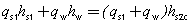

[0033] The invention is based on the cascade control system, adopts model reference self-adaptive control in the inner loop, and at the same time automatically adapts to the change of the object gain in the leading area, calculates the change of the object gain in the inert area according to the energy balance relationship in the water spraying and cooling process and obtains a correction factor. Then, the correction coefficient is introduced into the outer loop PID controller to correct the steam temperature deviation signal to realize the dynamic compensation function. Since the inertia of the controlled object in the inner loop in the cascade control system is very small, the calculated gain of the object in the inertia zone has good accuracy and real-time performance. The steam temperature control system after dynamic compensation is added. The original control quality of the system can be guaranteed when the desuperheating water hits the steam temperature measuring point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com