Intelligent cable automatic manufacturing machine based on fuzzy support vector machine

A technology of fuzzy support vector and manufacturing machine, which is applied in the direction of electronic commutation motor control, adaptive control, vector control system, etc. It can solve the problems of poor speed accuracy of the pulley drum, safety accidents, low degree of automation, etc., and achieve robustness Strong, strong generalization ability, improve the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

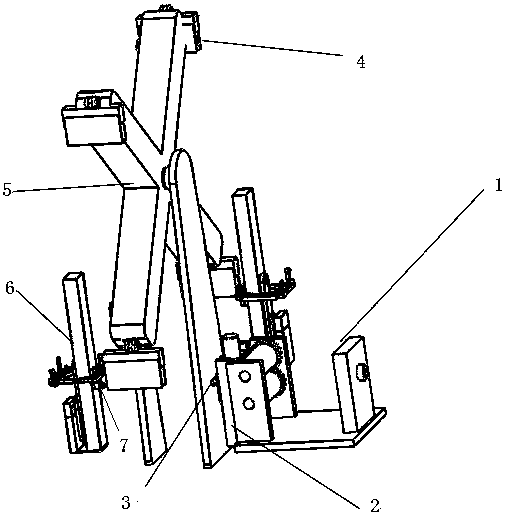

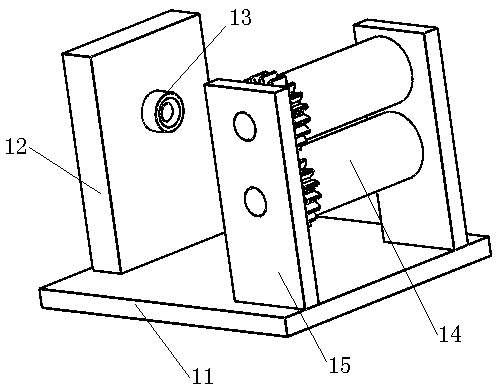

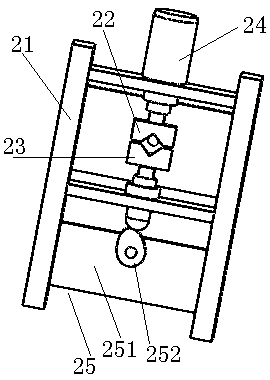

[0053] Attached below figure 1 -15 illustrates the technical solution of the present invention.

[0054] The present invention includes a wire inlet device 1, a peeling and thread cutting device 2, a skin twisting device 3, a wire clamping mechanism 4, a rotating conveying device 5, a needle pressing device 6, and a wire collection box 7. The wire inlet device 1 transports long cables to The stripping and cutting device 2, the stripping and cutting device 2 cuts the long cable into short cables of the required length, and performs ring cutting for the insulation at both ends of the short cable, and the insulation at both ends of the ring-cut short cable is twisted by rubbing The thread device 3 is stripped off, and the thread clamping mechanism 4 provided on the rotary conveying device 5 is sent to the needle pressing device 6 for needle pressing. The needle pressing device 6 is located on both sides of the rotating conveying device 5. Press the needle at both ends, set its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com