PID control parameter self-correction method based on closed-loop step response cascade loop

A step response, closed-loop technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems affecting the normal operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

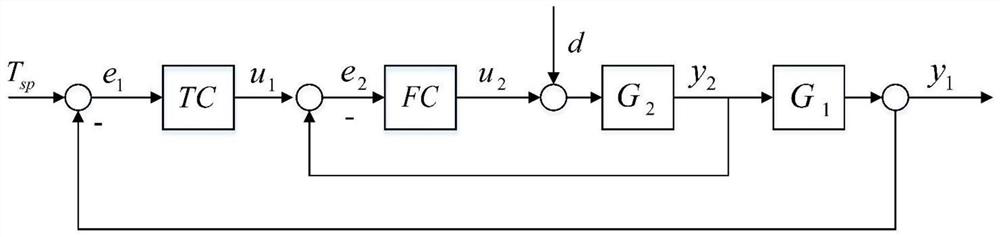

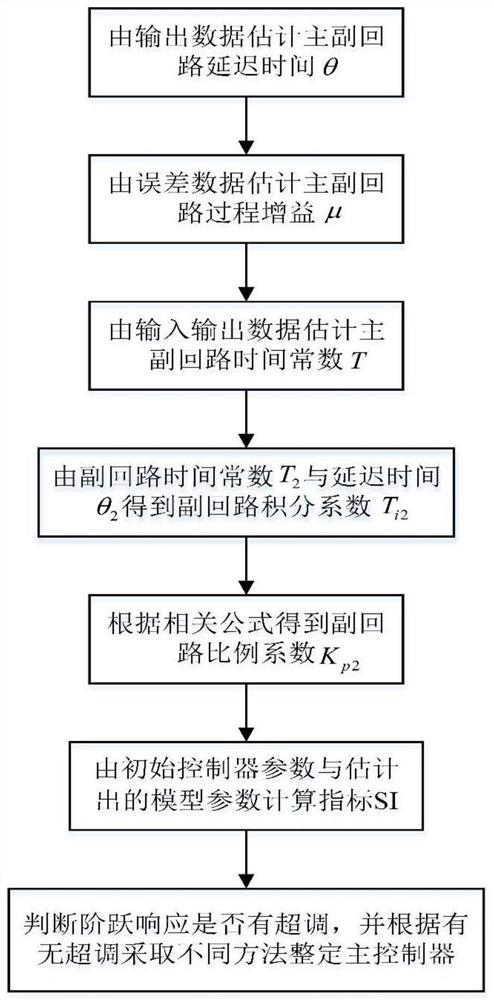

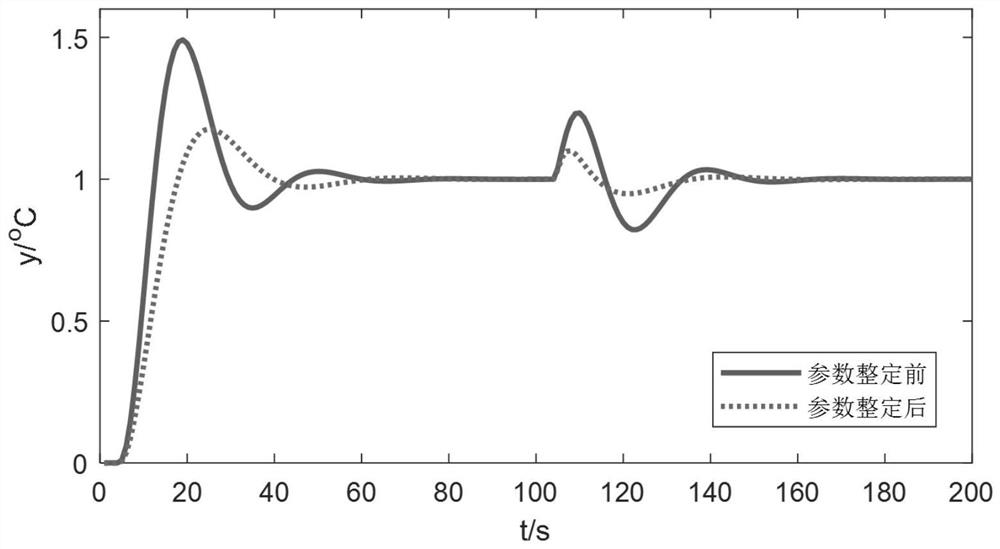

[0078] This embodiment provides a cascade loop parameter self-calibration method, the method comprising:

[0079] S1 collects the closed-loop step response data of the cascade controller applied in the controlled system, and estimates the model parameters of the controlled object of the main and secondary loops in the controlled system according to the closed-loop step response data;

[0080] The controlled object of the main loop of the cascade controller is:

[0081]

[0082] The controlled object of the secondary loop of the cascade controller is:

[0083]

[0084] where μ 1 ,μ 2 The process gains of the controlled objects of the main and secondary loops respectively, θ 1 ,θ 2 The delay time of the controlled objects of the main and secondary loops respectively, τ 1i ,τ 2 The time constants of the controlled objects of the main and secondary circuits respectively;

[0085] Under the action of the initial parameters of the cascade controller, the closed-loop ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com