Tension stability control system for film winding conveyance

A stable control and film winding technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., to achieve the effect of high control precision and small tension fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

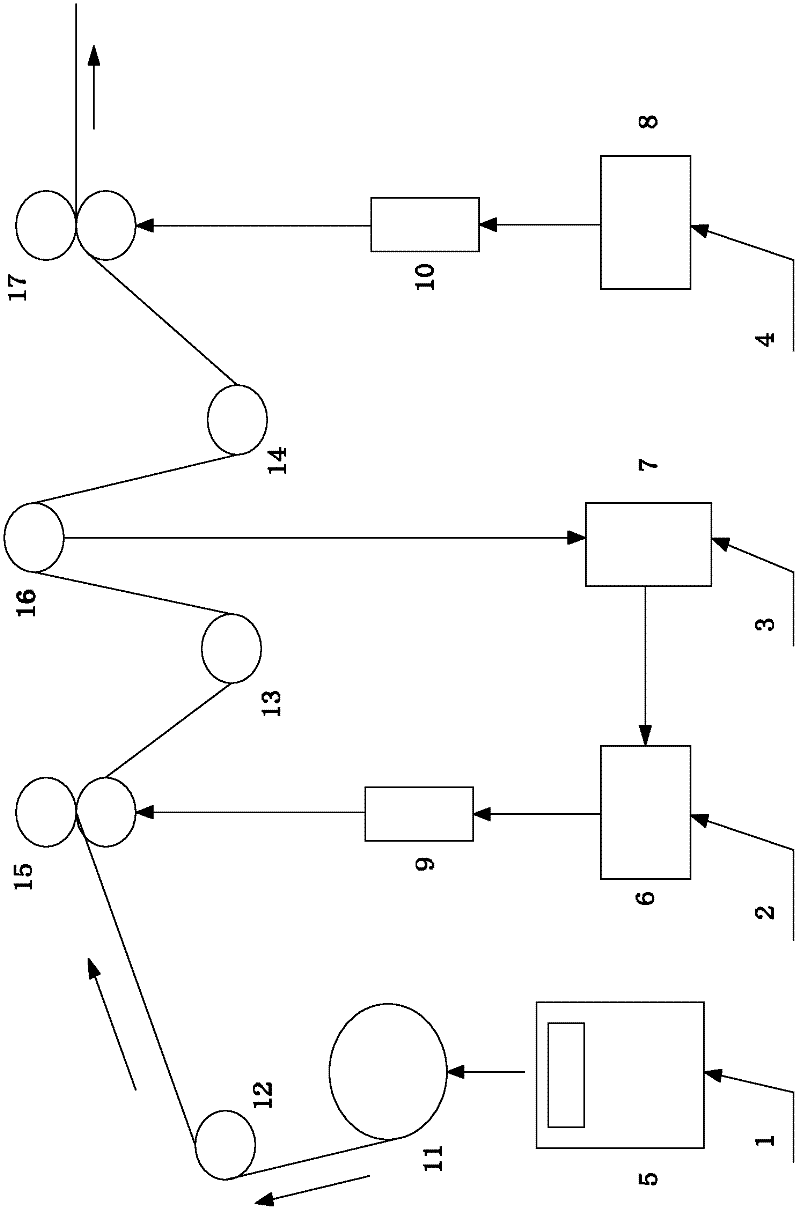

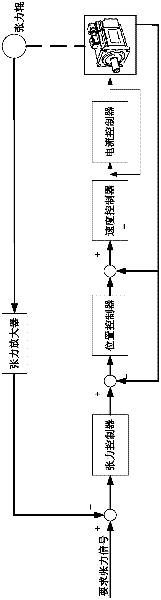

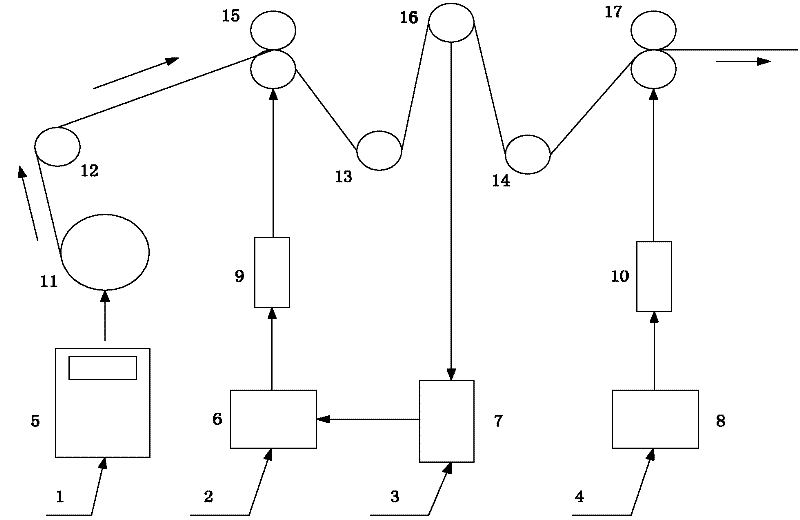

[0020] refer to figure 1 , a film winding and conveying tension stabilization control system, mainly includes a discharge roller 11, a driving pair of rollers 17, a driven pair of rollers 15, a tension roller 16 and a tension controller 7. The discharge roller 11 is composed of a material roll, an air shaft, and a magnetic powder brake 5. The material roll is fixed on the air shaft, and the end of the air shaft is connected to a magnetic powder brake. The magnetic powder brake is controlled by a magnetic powder controller 5, and the required discharge tension command is 1 As the input of the magnetic powder controller 5, the tension control of the discharging module adopts an open-loop control method. The active counter-roller 17 and the driven counter-roller 15 are driven by servo motors with 13-bit encoders. The amplifiers 9 and 10 are respectively configured by servo motors. The upper device of the amplifiers is realized by motion control card channels 6 and 8. Send the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com