Temperature cascade control system of casting holding furnace and control method of temperature cascade control system

A cascade control and holding furnace technology, applied in the field of automatic control system, can solve the problems of increased production cost and large fluctuation of furnace gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

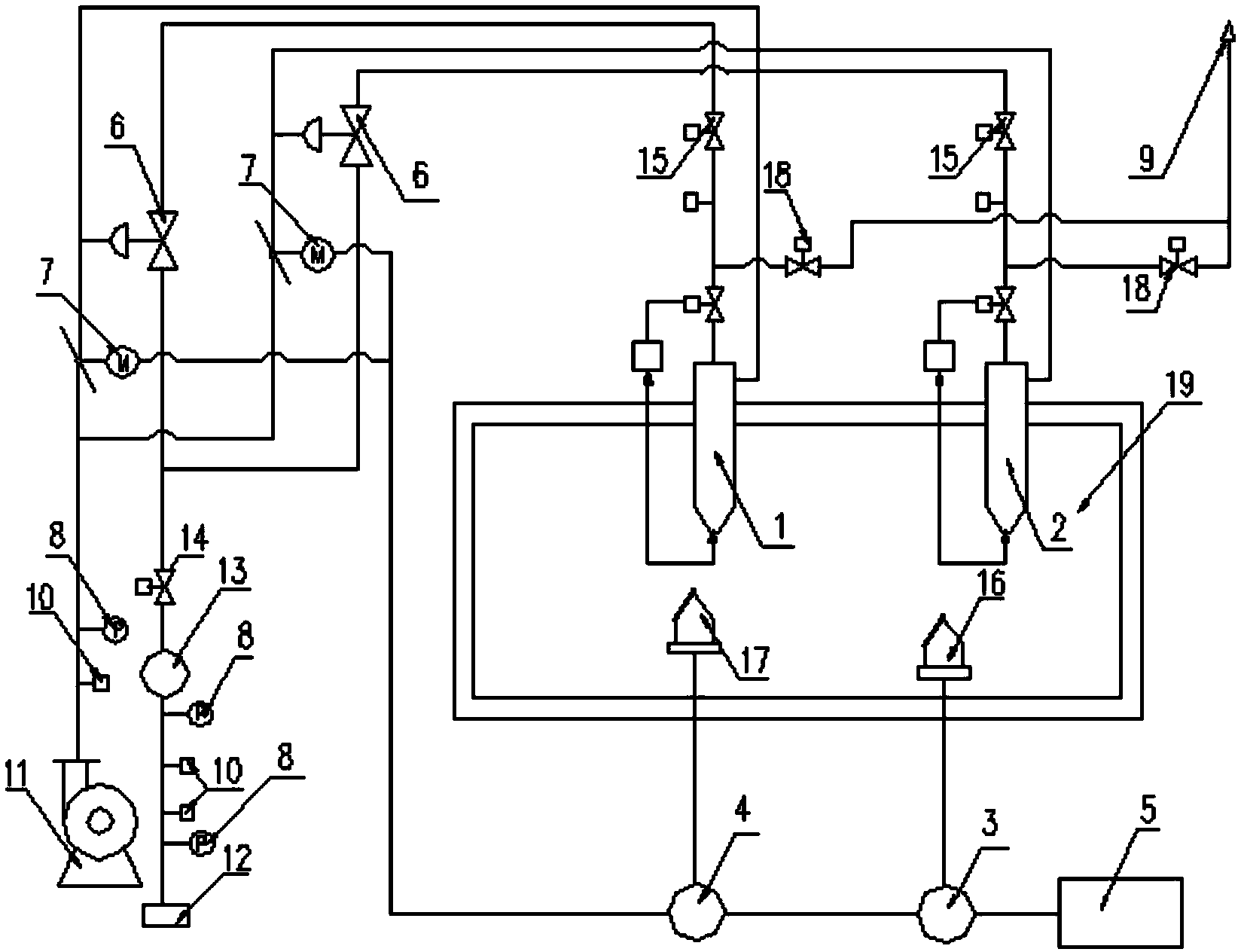

[0020] Such as figure 1 As shown, the temperature cascade control system of the melting and casting holding furnace of the present invention includes a holding furnace 19, a furnace gas temperature thermocouple 16, a molten metal temperature thermocouple 17, an air control gas proportional valve 6, a combustion air regulating valve 7, a first burner Nozzle 1, second burner 2, first PLC controller 3, second PLC controller 4, combustion fan 11, natural gas output port 12 and man-machine interface 5. The first burner 1 and the second burner 2 are installed on the holding furnace 19, and the burner openings of the two burners are located inside the holding furnace 19, and the first burner 1 is connected to the combustion-supporting fan 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com