Recovering and purifying device of organic solvent and method

An organic solvent and fan technology, which is applied in the field of organic solvent recovery and purification devices, can solve the problems affecting the quality of recovered materials, etc., and achieve the effects of being conducive to condensation separation, reducing the possibility of chemical changes, and reducing secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

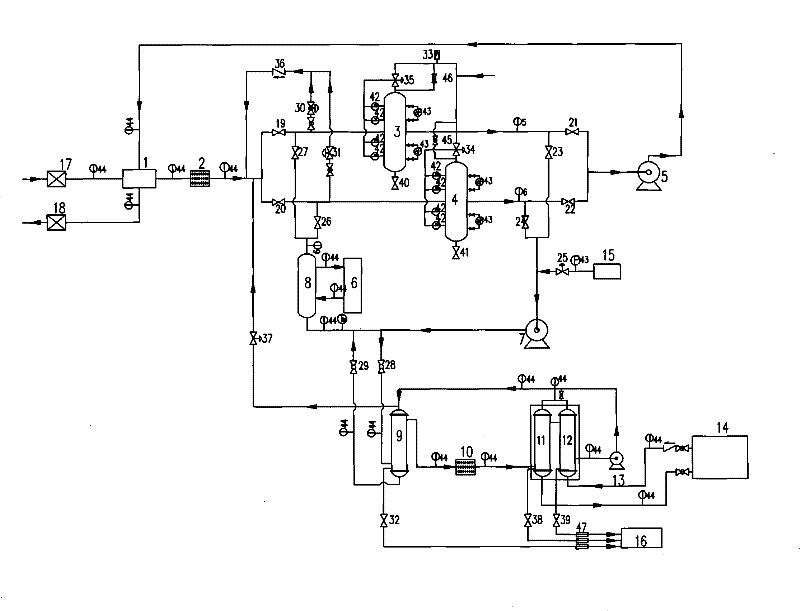

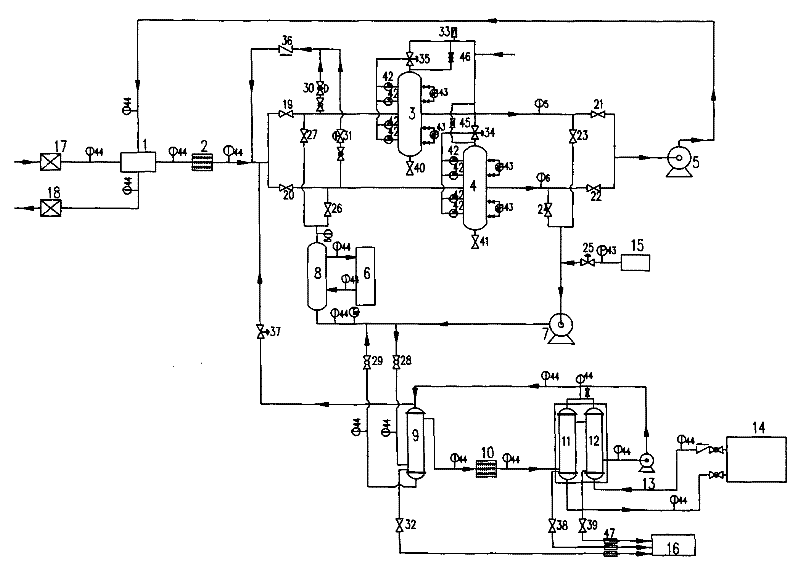

[0029]An organic solvent recovery and purification device consists of a first heat exchanger 1, a first air cooler 2, a first adsorber 3, a second adsorber 4, a first fan 5, an oil furnace 6, a second fan 7, and an oil heater 8. Second heat exchanger 9, second air cooler 10, first condenser 11, second condenser 12, third fan 13, water cooler 14, gas cylinder 15, solvent recovery tank 16, first flame arrester 17. The second flame arrester 18, the first valve 19, the fifth valve 20, the second valve 21, the seventh valve 22, the fourth valve 23, the eighth valve 24, the fourteenth valve 25, the sixth valve 26, the Three valves 27, eleventh valves 28, twelfth valves 29, ninth valves 30, tenth valves 31, thirteenth valves 32, fifteenth valves 33, sixteenth valves 34, seventeenth valves 35, Oxygen sensor 36, nineteenth valve 37, twentieth valve 38, twenty-first valve 39, twenty-third valve 40, twenty-fourth valve 41, temperature transmitter 42, pressure transmitter 43, temperature ...

Embodiment 2

[0046] Adopting the device described in embodiment 1, taking the first adsorber 3 as an example, the method for reclaiming and purifying the organic solvent by the above-mentioned device is as follows:

[0047] Pre-cool organic solvents containing xylene and petroleum hydrocarbons to 100°C, then cool to 40°C, open the first valve 19 and the second valve 21, pass the cooled waste gas into the first adsorber 3, and put the adsorbed waste gas into the first adsorber 3. The exhaust gas is preheated to 200°C and then output; when the concentration of organic solvent is 2000ppm, the adsorption time is generally 8 hours. After the adsorption time arrives, close the first valve 19 and the second valve 21, open the third valve 27 and the fourth valve 23, open the oil heater 8 and the oil furnace 6, and open the second fan 7 after 10 minutes to preheat The gas with low oxygen content up to 300°C is passed into the first adsorber 3 for desorption; when the temperature of the adsorber exc...

Embodiment 3

[0053] Adopting the device described in embodiment 1, taking the first adsorber 3 as an example, the method for reclaiming and purifying the organic solvent by the above-mentioned device is as follows:

[0054]Pre-cool organic solvents containing xylene and petroleum hydrocarbons to 60°C, then cool to 20°C, open the first valve 19 and the second valve 21, pass the cooled waste gas into the first adsorber 3, and put the adsorbed waste gas into the first adsorber 3. The exhaust gas is preheated to 150°C and then output; when the concentration of organic solvent is 2000ppm, the adsorption time is generally 8 hours. After the adsorption time arrives, close the first valve 19 and the second valve 21, open the third valve 27 and the fourth valve 23, open the oil heater 8 and the oil furnace 6, and open the second fan 7 after 10 minutes to preheat The gas with low oxygen content up to 200°C is passed into the first adsorber 3 for desorption; when the temperature of the adsorber excee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com