Horizontal moderately thick mine body compartment type filling mining method

A mining method and box filling technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of gob subsidence and low recovery rate, reduce the difficulty of management, improve environmental protection, and reduce unit costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

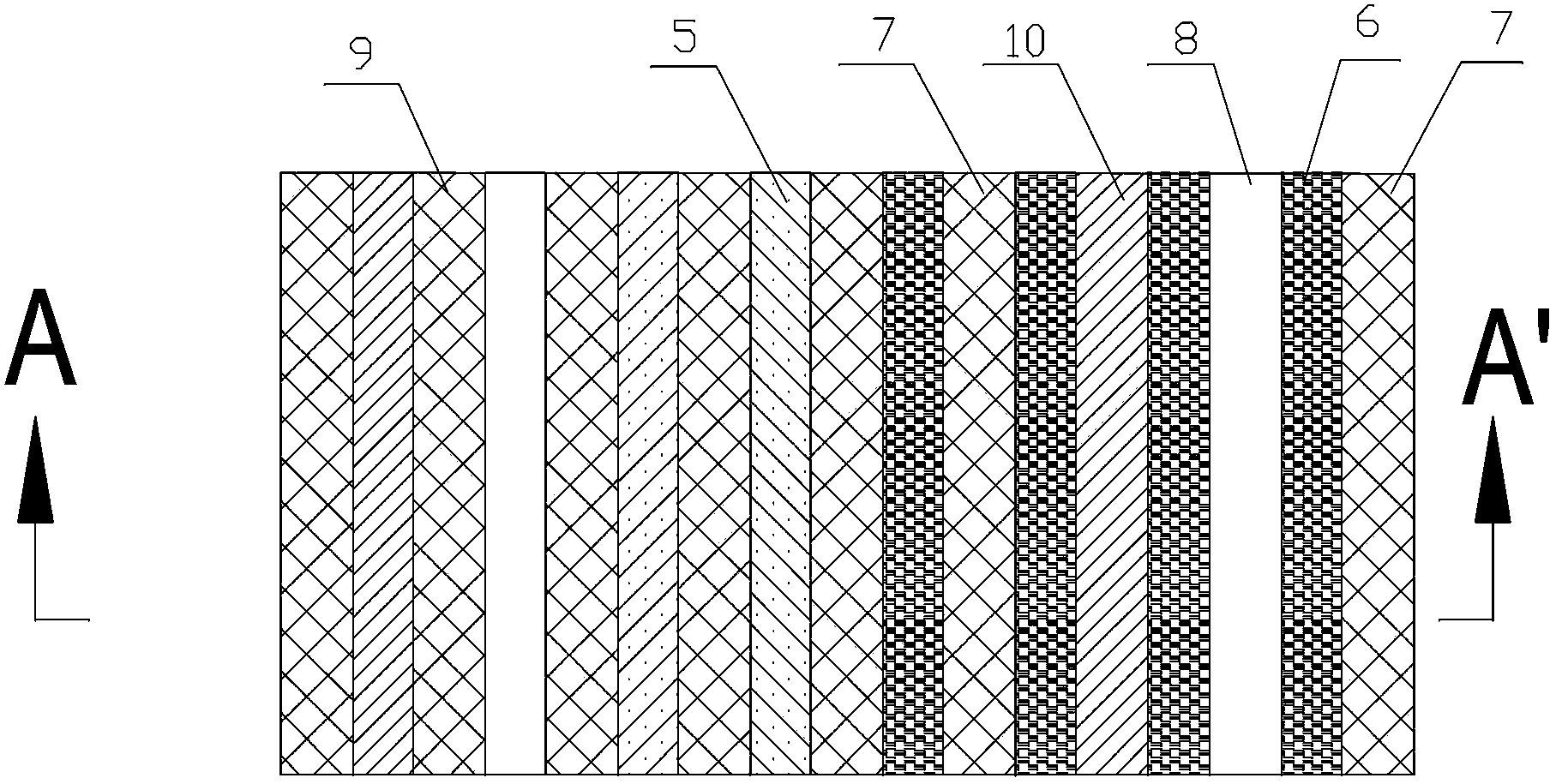

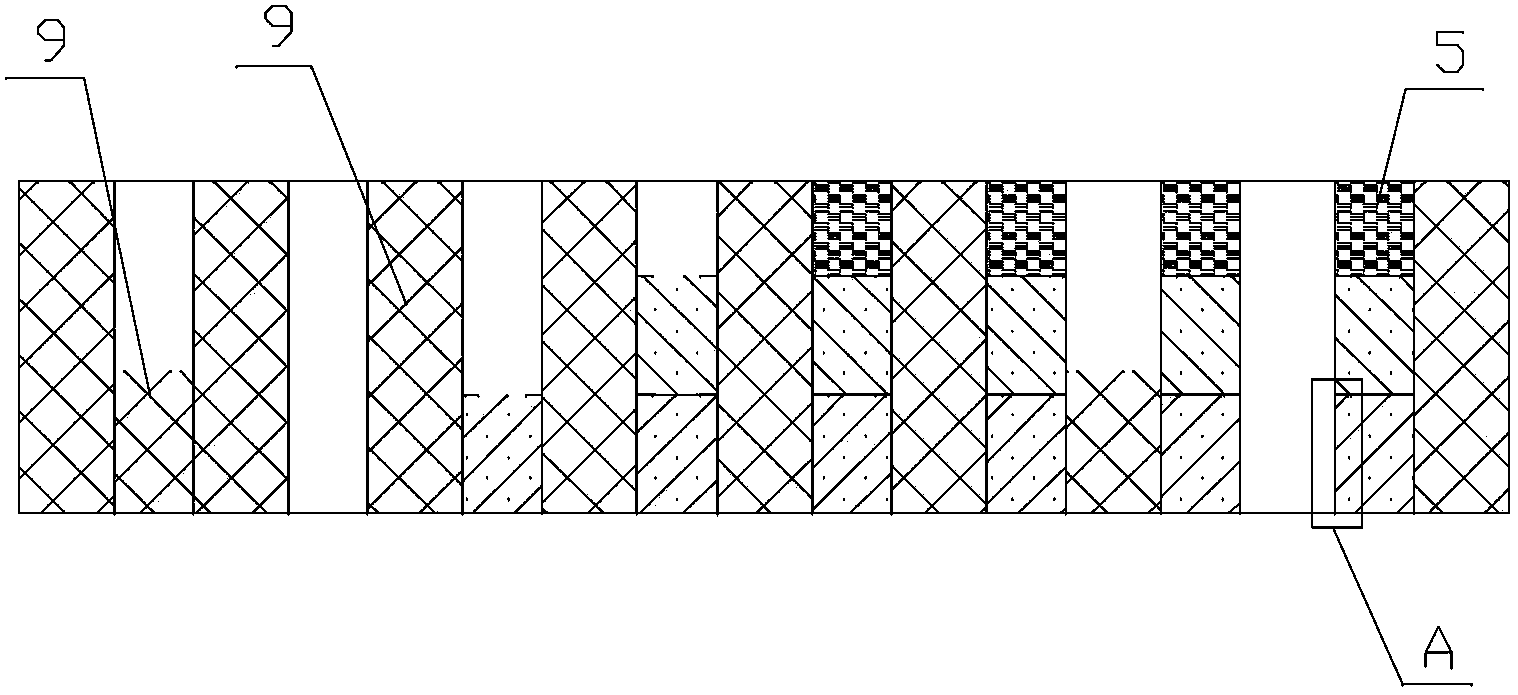

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as Figure 4 As shown, the mining method of this embodiment is as follows:

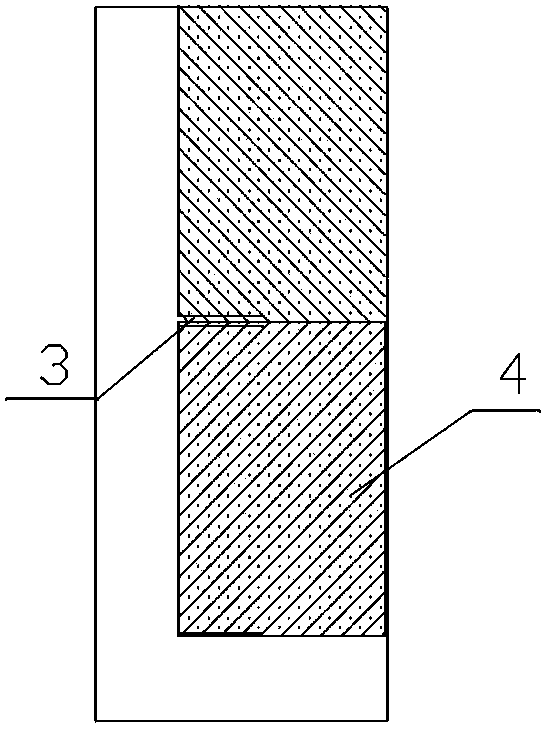

[0026] Step (1) Roof cutting: Excavate the upper channel along the roof of the mine. It is required that the upper channel must be constructed along the roof of the mine. The ore in the upper channel should be removed at one time. The height of the roof cutting can be 3-5m, and the width of the upper channel and the bottom road 4.5---6m.

[0027] Step (2) Roof protection: It is required that the progress of the roof protection must be close to the roof cutting working face, and the bolt connection bars or the bolt connection bars are used for spraying support. Figure 4 (a) shows step (1) and step (2). First, excavate 2 upper passages along the roof of the ore seam. Passage 1 and passage 2 reach the boundary of the mine house, which is the roof cutting. No top and bottom pillar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com