Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

A slow-release compound fertilizer and tailings technology, which is applied in the form of fertilizers, fertilization devices, fertilizer mixtures, etc., can solve the problems of many production process steps, high production costs, and increased burden on agricultural practitioners, and solve the problem of stacking, The effect of low cost and loss prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

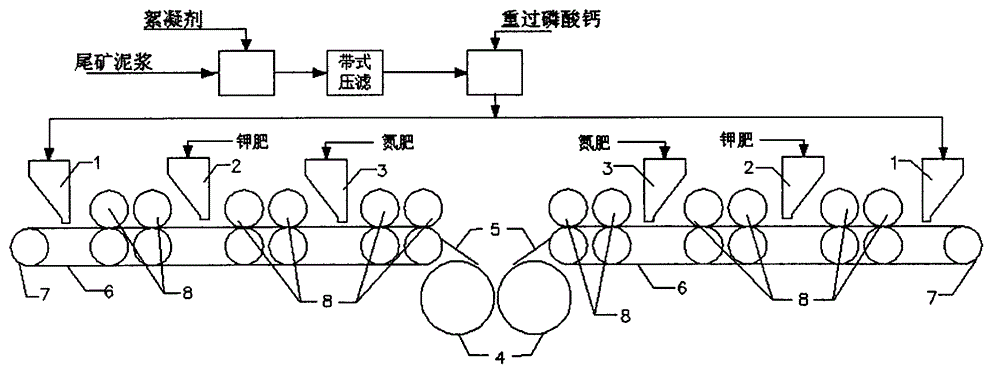

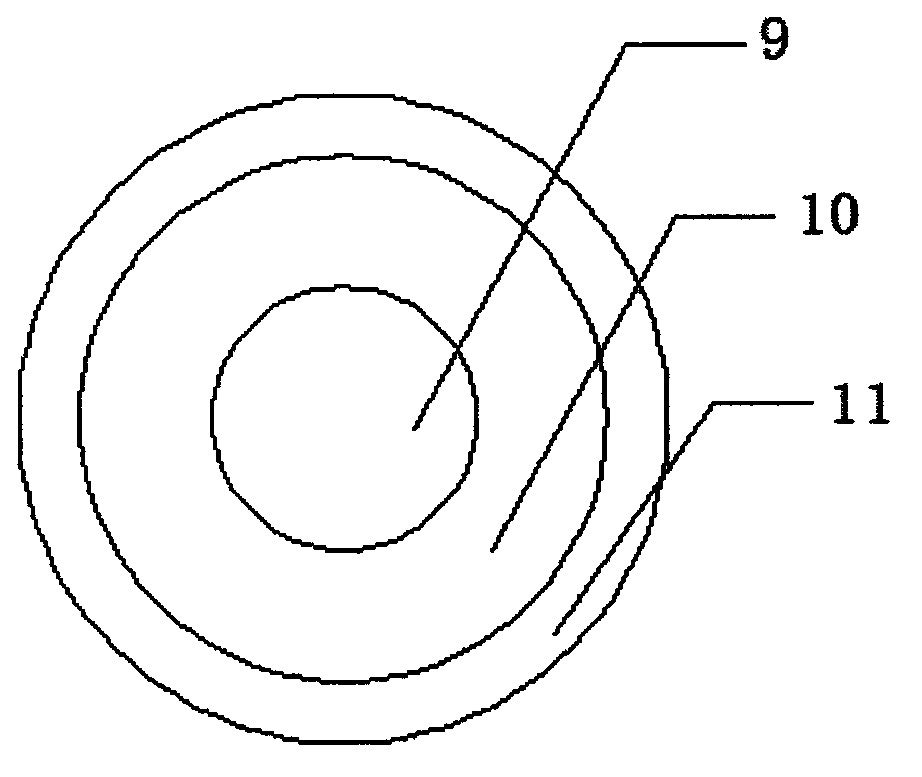

[0030] Such as figure 1 Shown, add the chitosan of tailings mud weight 0.01% in the tailings mud (chitosan is dissolved with an appropriate amount of organic acid, such as acetic acid, oxalic acid, citric acid before use), mix well, filter with belt type Machine pressure filtration, the water content of the obtained filter mud is 40%, add heavy superphosphate to the filter mud, mix it evenly, put it into the slurry hopper of the fertilizer granulator, and sprinkle it evenly on the conveyor belt from the slurry hopper, The strip-shaped phosphate fertilizer mineral layer is formed by calendering by the calender roller group; potassium chloride falls from the potassium fertilizer hopper, and is evenly sprinkled on the phosphate fertilizer mineral layer, and a certain thickness of the potassium fertilizer layer is formed by calendering by the calender roller group; then urea is evenly sprinkled on the potassium fertilizer layer , through the calendering of the calendering roller g...

Embodiment 2

[0032] Such as figure 1 As shown, add 0.015% of the tailings slime weight esterified modified starch into the tailings slime, mix evenly, press filter with a belt filter press, the water content of the obtained filter mud is 45%, and add dihydrogen phosphate to the filter mud Potassium, after mixing evenly, put it into the slurry hopper of the fertilizer granulator, sprinkle it evenly on the conveyor belt from the slurry hopper, and form a strip-shaped phosphate fertilizer mineral layer through the calendering of the calender roller group; potassium sulfate falls from the potassium fertilizer hopper, sprinkle it evenly On the phosphate fertilizer mineral layer, a potassium fertilizer layer of a certain thickness is formed by calendering rollers; then ammonium bicarbonate is evenly sprinkled on the potassium fertilizer layer, and a nitrogen fertilizer layer of a certain thickness is formed by calendering rollers, which is transported by belts and pallets , enter the hemispheric...

Embodiment 3

[0034] Such as figure 1As shown, add 0.02% sodium carboxymethyl starch of the tailings mud to the tailings mud, mix evenly, press filter with a belt filter press, the water content of the obtained filter mud is 50%, add calcium and magnesium in the filter mud Phosphate fertilizer, after mixing evenly, put it into the slurry hopper of the fertilizer granulator, sprinkle it evenly on the conveyor belt from the slurry hopper, and form a strip-shaped phosphate fertilizer mineral layer through the calendering of the calender roller group; potassium nitrate falls from the potassium fertilizer hopper, sprinkle it evenly On the phosphate fertilizer mineral layer, a potassium fertilizer layer of a certain thickness is formed by calendering of the calendering roller group; then ammonium nitrate is evenly sprinkled on the potash fertilizer layer, and a nitrogen fertilizer layer of a certain thickness is formed by calendering of the calendering roller group, which is transported by the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com