Fully automatic cotton picker

A cotton picking machine, fully automatic technology, applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of cotton farmers' economic losses, reduce the competitiveness of cotton market, and expensive prices, so as to reduce subsequent processing costs and reduce The cost of picking and the effect of ensuring the quality of cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

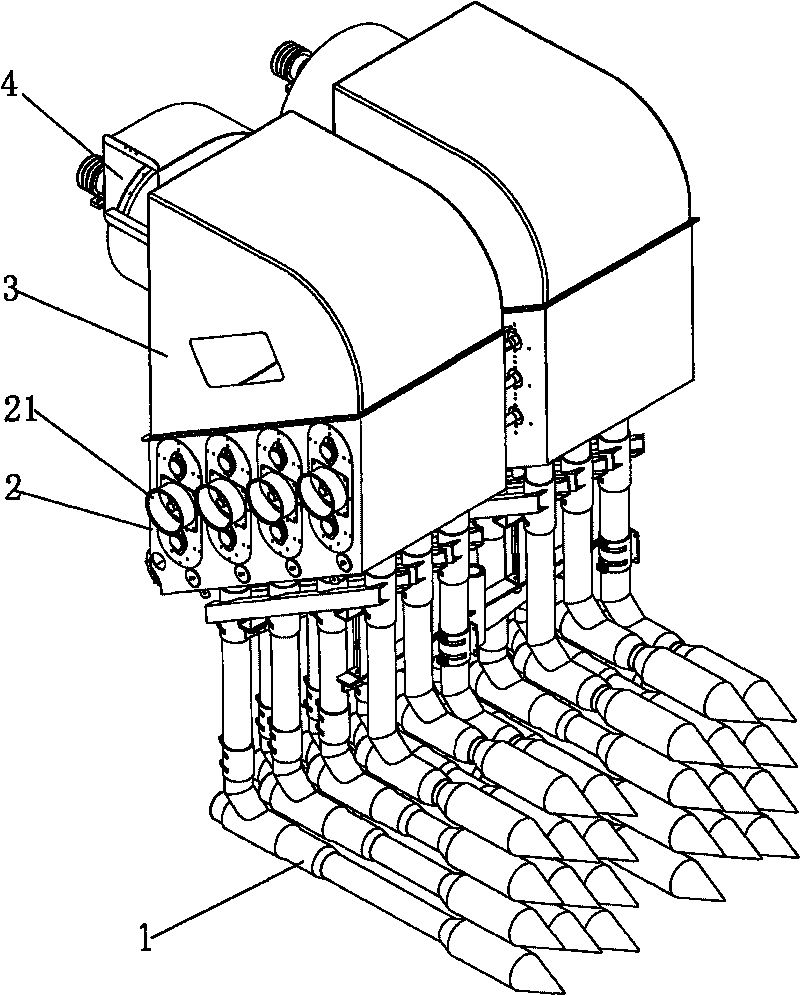

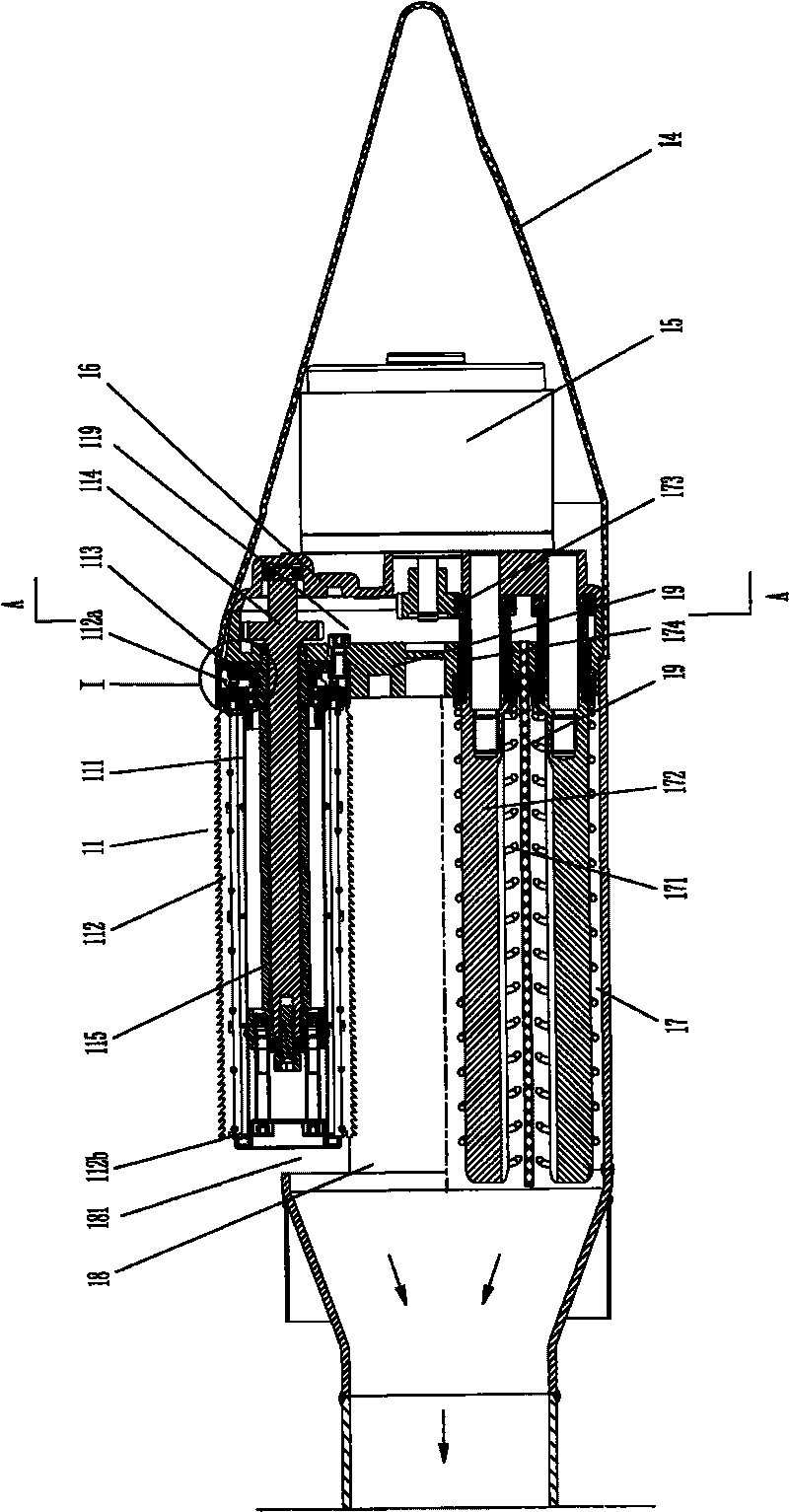

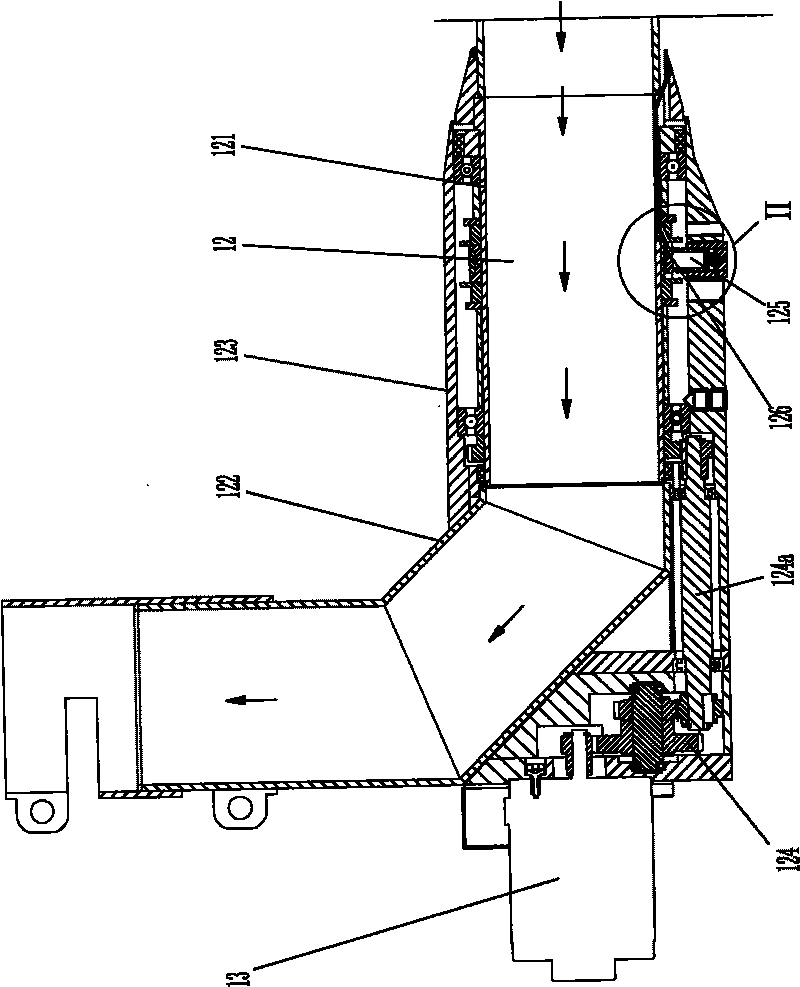

[0043] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the structure of the picking head assembly, image 3 It is a schematic diagram of the structure of the vacuum suction conveying channel, Figure 4 for figure 2 Enlarged view at I, Figure 5 for image 3 Enlarged view at II, Figure 6 is the plan view of the cam groove on the cam disc, Figure 7 for figure 2 Sectional view along A-A direction, Figure 8 A schematic diagram of the rack structure, Figure 9 Assemble a stereogram for the picking head, Figure 10 Schematic diagram of the separation mechanism assembly, Figure 11 for Figure 9 Sectional view along B-B direction, Figure 12 It is a three-dimensional diagram of the separation mechanism, as shown in the figure: the direction of the arrow in the figure is the direction of cotton flow; the fully automatic cotton picker of this embodiment includes a body, a cotton picking device 1 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com