Copper sponge preparation process by reducing copper contained acidic leachate with iron powder

A technology of acidic leaching solution and process method, which is applied in the field of chemical production and manufacturing, can solve the problems of large pollution, low degree of automation, and high labor intensity, and achieve the effects of reducing labor intensity, improving production efficiency, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

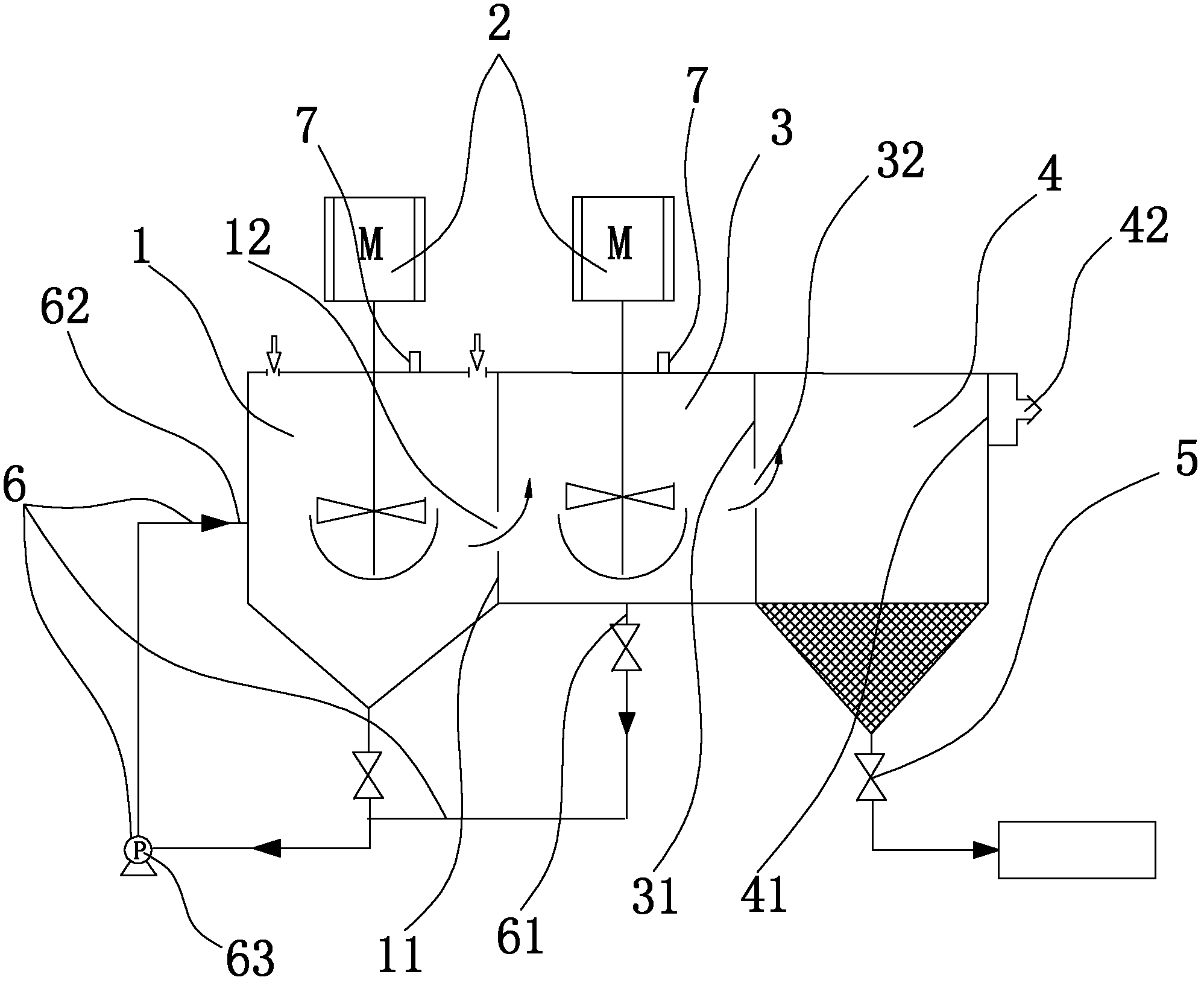

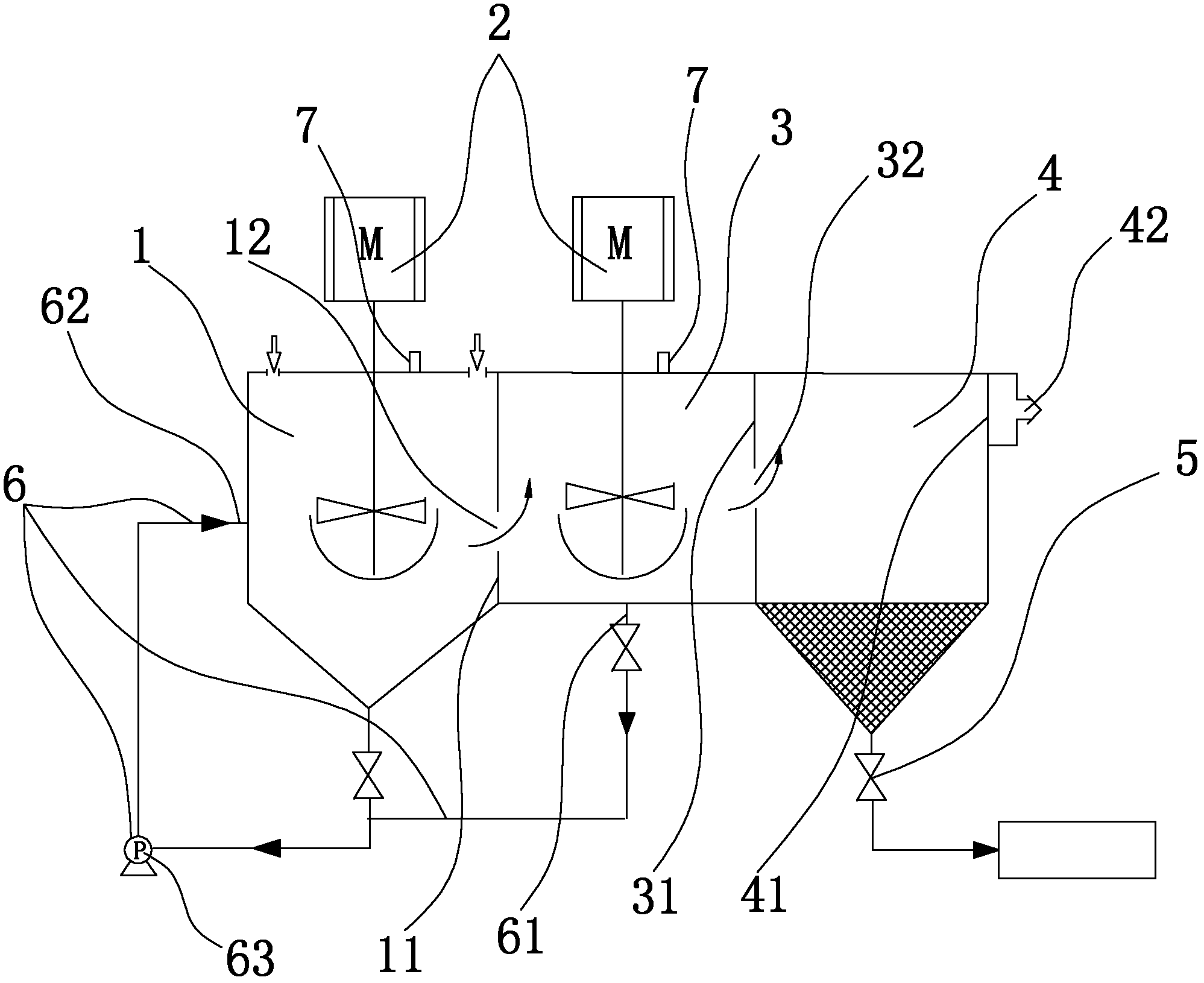

[0035] The acidic leaching solution of a resource-type copper mine with a copper content of 3g / l and a pH of 1.2, and reduced iron powder with an iron content of 96%, are controlled at a rate of 30m3 / h for the leachate flow rate and 193kg / h for the mass flow rate of the iron powder. , join in the main reaction tank 1 of continuous reactor simultaneously respectively, and open stirrer 2, wherein the rotating speed of the stirrer 2 in the main reaction tank 1 is 50rpm, the rotating speed of the stirrer 2 in the intermediate reaction tank 3 is 20rpm, And control the reaction time from entering the main reaction tank 1 to collecting the sponge copper in the settling tank 4 for copper-containing acidic leaching solution and iron powder to be 5 hours, continuous operation for 48 hours, and sampling and analysis at regular intervals to obtain the copper content of the continuous reduction process. The yields are all higher than 95%, and the average yield is 97.2%.

Embodiment 2

[0037] The acidic leaching solution of a resource-type copper mine with a copper content of 8g / l and a pH of 0.8, and reduced iron powder with an iron content of 96%, are controlled at a rate of 50m3 / h for the leachate flow rate and 420kg / h for the mass flow rate of the iron powder. , respectively join in the main reaction tank 1 of continuous reactor simultaneously, and open stirrer 2, wherein the rotating speed of the stirrer 2 in the main reaction tank 1 is 80rpm, the rotating speed of the stirrer 2 in the intermediate reaction tank 3 is 20rpm, And control the reaction time from entering the main reaction tank 1 to collecting the sponge copper in the settling tank 4 for copper-containing acidic leaching solution and iron powder to be 4 hours, continuous operation for 36 hours, and sampling and analysis at regular intervals to obtain the copper content of the continuous reduction process. The yields are all higher than 95%, and the average yield is 96.7%.

Embodiment 3

[0039] The acidic leaching solution of a resource-type copper mine with a copper content of 14g / l and a pH of 0.5, and reduced iron powder with an iron content of 96%, are controlled at a rate of 60m3 / h for the flow rate of the leaching solution and a mass flow rate of 880kg / h for the iron powder. Join respectively in the main reactor 1 of continuous reactor simultaneously, and open agitator 2, wherein the rotating speed of agitator 2 in main reaction tank 1 is 100rpm, the rotating speed of agitator 2 in intermediate reaction tank 3 is 20rpm, and Control the reaction time of copper-containing acidic leaching solution and iron powder from entering the main reaction tank 1 to collecting sponge copper in the settling tank 4 as 3 hours, continuous operation for 36 hours, and sampling and analysis at regular intervals to obtain the copper recovery of the continuous reduction process. The yields are all higher than 94.5%, and the average yield is 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com