Method for extracting purified Tth DNA polymerases

A technology of polymerase and engineering bacteria, applied in the biological field, can solve the problems of affecting enzyme amplification and reverse transcription activity, difficulty in large-scale cultivation, expensive equipment, etc., to ensure the effect of reverse transcription and gene amplification, and reduce non-specific adsorption Opportunities, effects on product yield and purity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

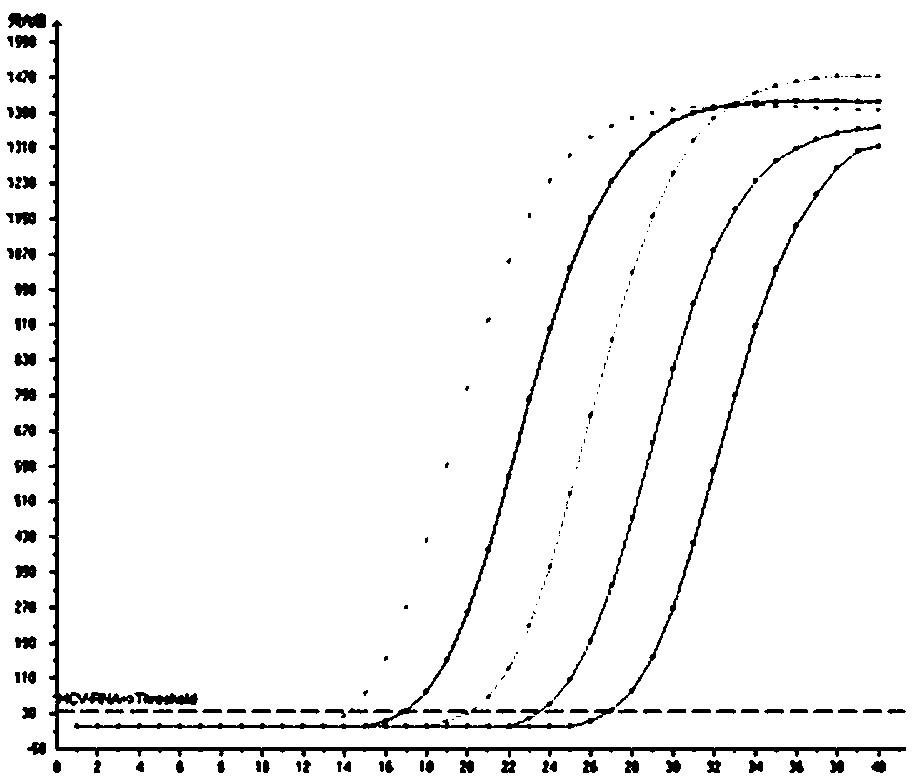

Image

Examples

Embodiment 1

[0052] 1. Preparation of main reagents

[0053] 1. LB liquid medium (1000 mL)

[0054] NaCl: 10g

[0055] Peptone: 10g

[0057] 2. Buffer A (20mM Tris-HCl, 0.2M NaCl, pH 8.0) (1000 mL)

[0058] Trizma-HCl: 1.7651g

[0059] Trizma-Base: 1.066g

[0060] NaCl: 11.688g

[0061] 3. Buffer B (20mM Tris-HCl, 0.5M NaCl, pH 8.0) (1000 mL)

[0062] Trizma-HCl: 1.7651g

[0063] Trizma-Base: 1.066g

[0064] NaCl: 29.22g

[0065] 4. Wash buffer C: (20mM Tris-HCl, 0.5M NaCl, 5mM imidazole, 0.5% Tween-20, pH 8.0) (100 mL)

[0066] Buffer B: 100mL

[0067] 3M imidazole: 167uL

[0068] Tween-20: 500uL

[0069] 5. Wash buffer D: (20mM Tris-HCl, 0.5M NaCl, 5mM imidazole, pH 8.0) (100 mL)

[0070] Buffer B: 100mL

[0071] 3M imidazole: 167uL

[0072] 2. Construction and expression of Tth DNA polymerase engineering bacteria

[0073] 1. Construction of Tth DNA polymerase engineering bacteria

[0074] The template is a plasmid containing the gene of Thermu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com