''U-and-U plus upper corner pump drainage'' stoping surface gas control method

A corner and gas technology, applied in the field of gas control in the "U and U + upper corner extraction" mining face, can solve the problems of large gas emission in the goaf, restricting safe production of the mining face, abnormal gas emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be clearly described below in conjunction with the drawings and specific embodiments in the embodiments of the present invention. The description here is only used to explain the present invention, but not as a limitation to the present invention. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without creative work, any modifications, equivalent replacements, improvements, etc., shall be included in the protection scope of the present invention Inside.

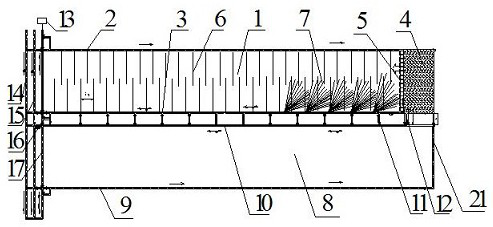

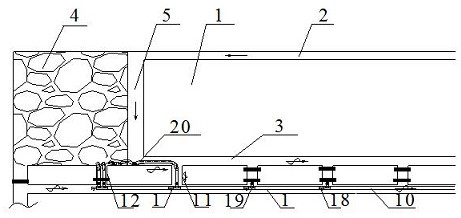

[0024] Such as Figure 1-2 As shown, the present invention proposes a "U and U + upper corner drainage" gas control method for the mining face, including the "U and U" roadway layout, the construction of the underground fixed drainage pumping station system, and the common air inlet lane of the mining face. Bedding drilling construction, ordinary bedding drilling construction in the return airway of the mining face, high-level dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com