A Safe and Clean Ventilation System Applicable to the Mining Face of the Roof Cutting and Pressure Relief 110 Method

A roof cutting pressure relief and ventilation system technology, applied in mine/tunnel ventilation, mining equipment, earthwork drilling and mining, etc., can solve the problems of personnel health impact, toxic and harmful gas concentration exceeding the limit, and high dust concentration in the operation area. To achieve the effect of eliminating the concentration of toxic and harmful gases exceeding the limit, reducing the risk of spontaneous combustion of coal residues, and preventing gas disasters and accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

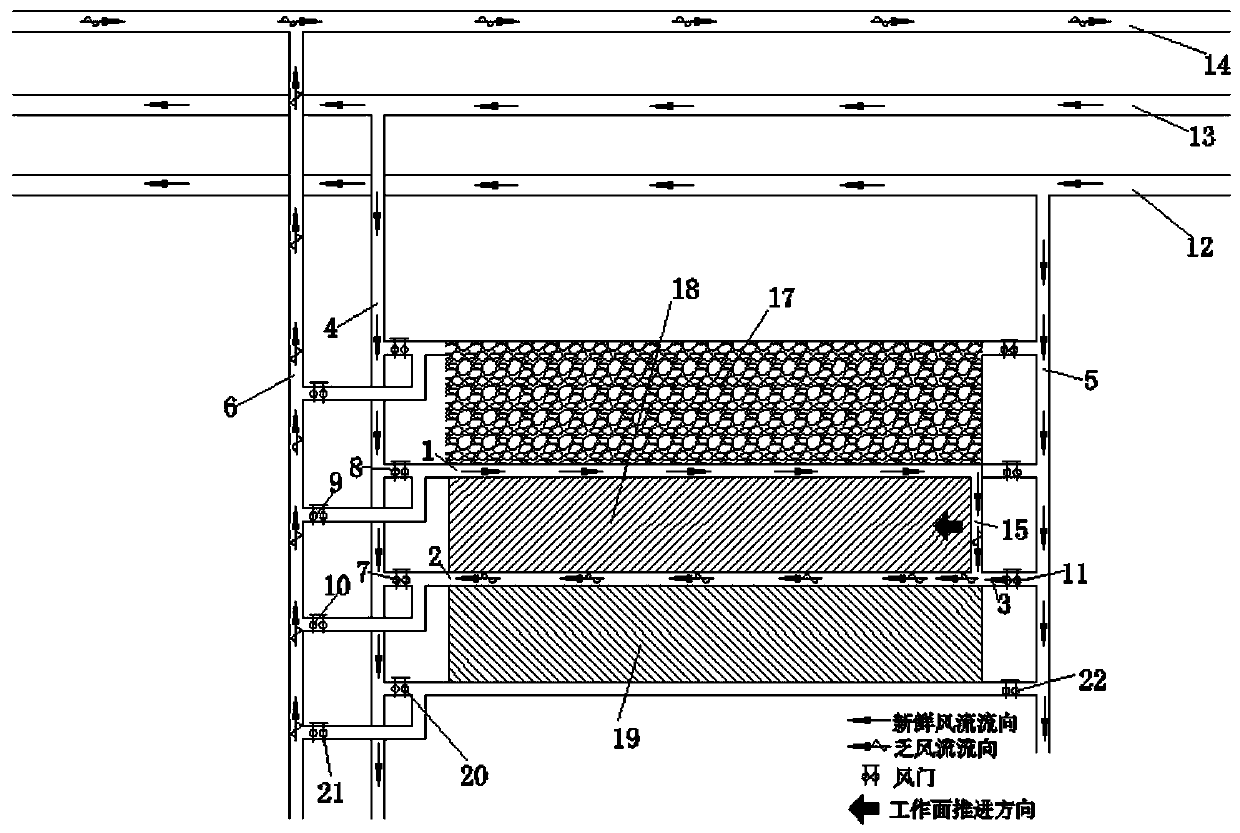

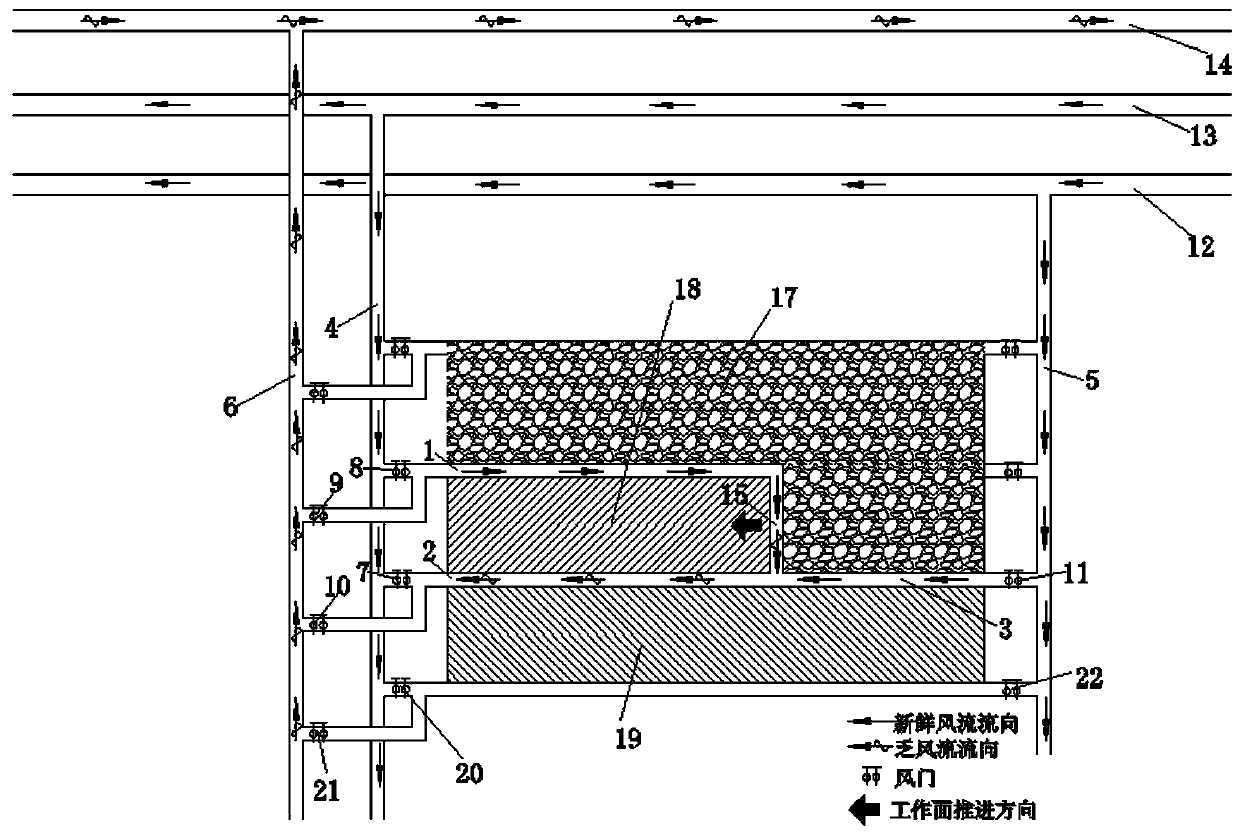

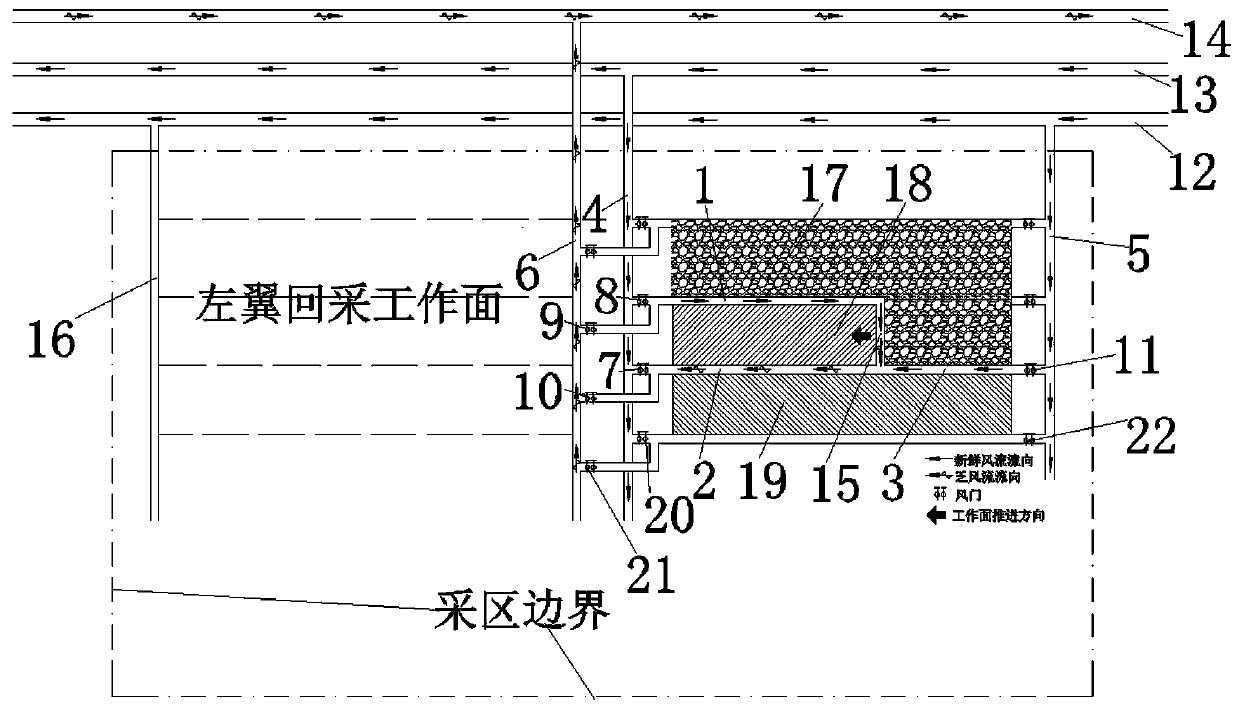

[0020] Such as image 3 As shown, a safe and clean ventilation system suitable for the mining face of the 110 method of roof cutting and pressure relief, including the return air downhill roadway 6 in the mining area and the belt downhill roadway 4 in the mining area, which are located in the center of the mining area and run through the entire mining area. The return air downhill roadway 6 is located on the left side of the tape downhill roadway 4 in the mining area, and the right side of the tape downhill roadway 4 in the mining area is the right wing recovery working face. The track downhill roadway 5 is also used as the right boundary air inlet lane, and the left side of the return air downhill roadway 6 in the mining area is the left wing recovery working face. There is a left boundary track downhill roadway 16 that runs through the entire mining area at the left boundary of the mining area. The roadway 16 is also used as the air inlet lane on the left boundary. The mine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com