Patents

Literature

40results about How to "Solve the overrun problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

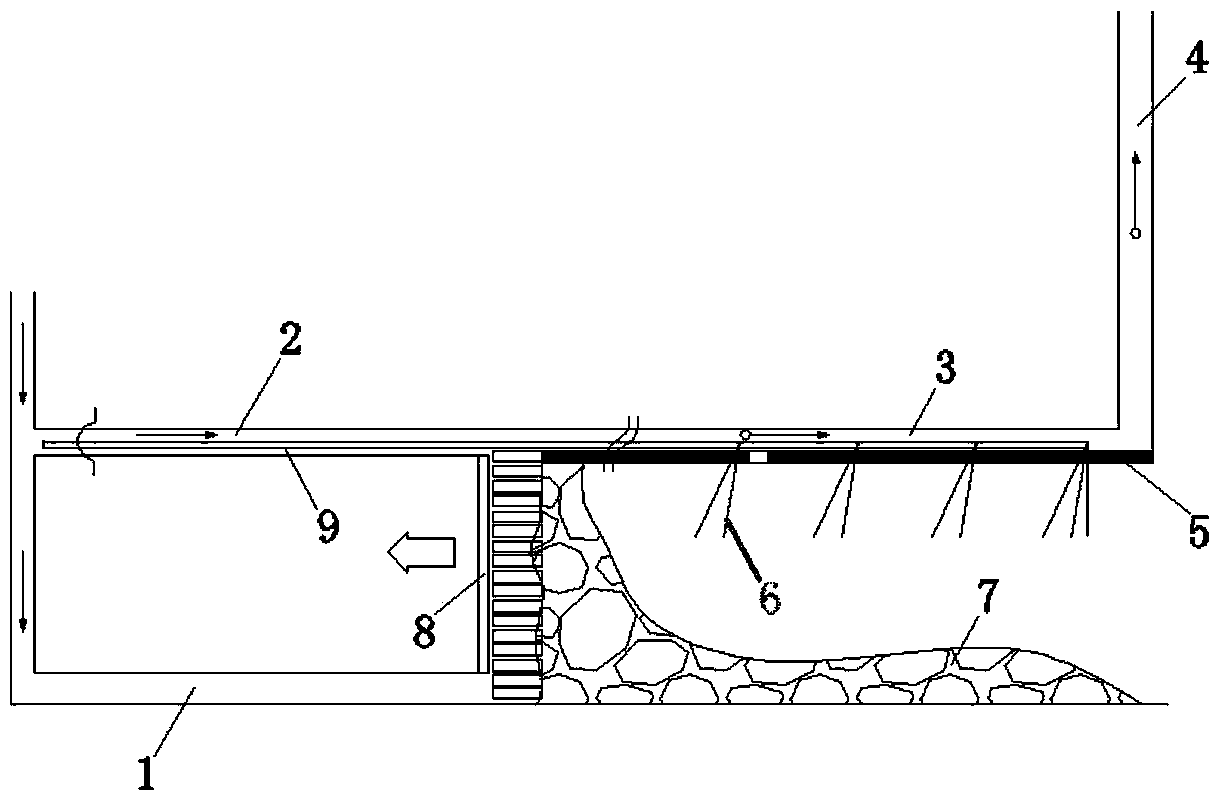

Method for arranging roadways on coal-pillar-free stope

InactiveCN102392642ASolve the overrun problemAlleviate mining tensionsUnderground miningSurface miningDual purposeEngineering

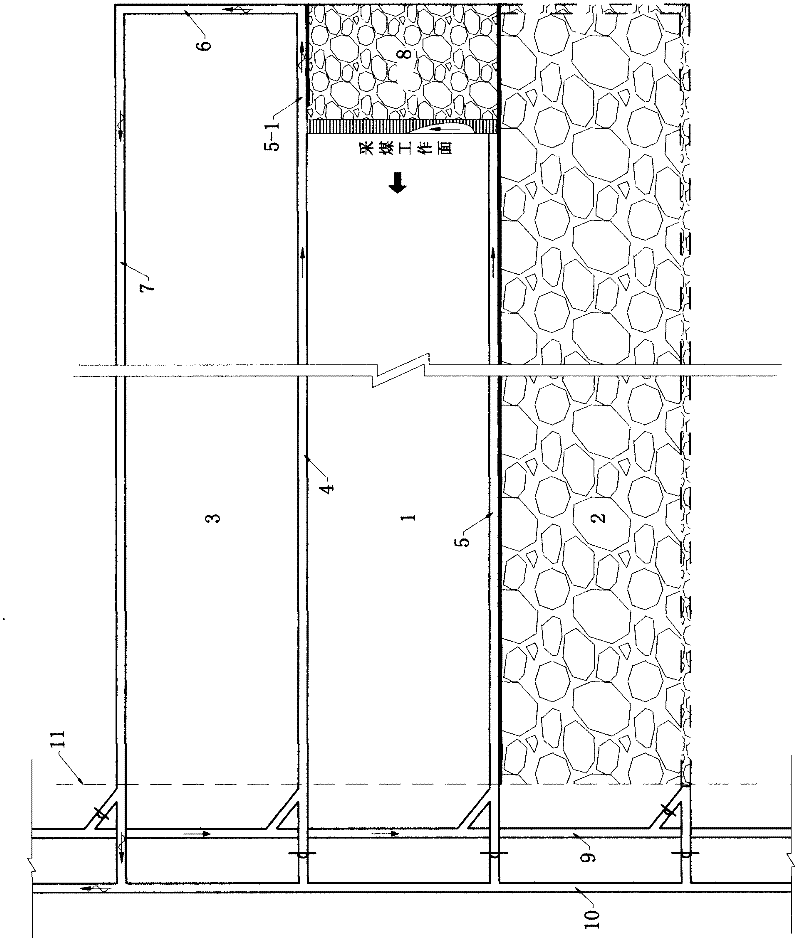

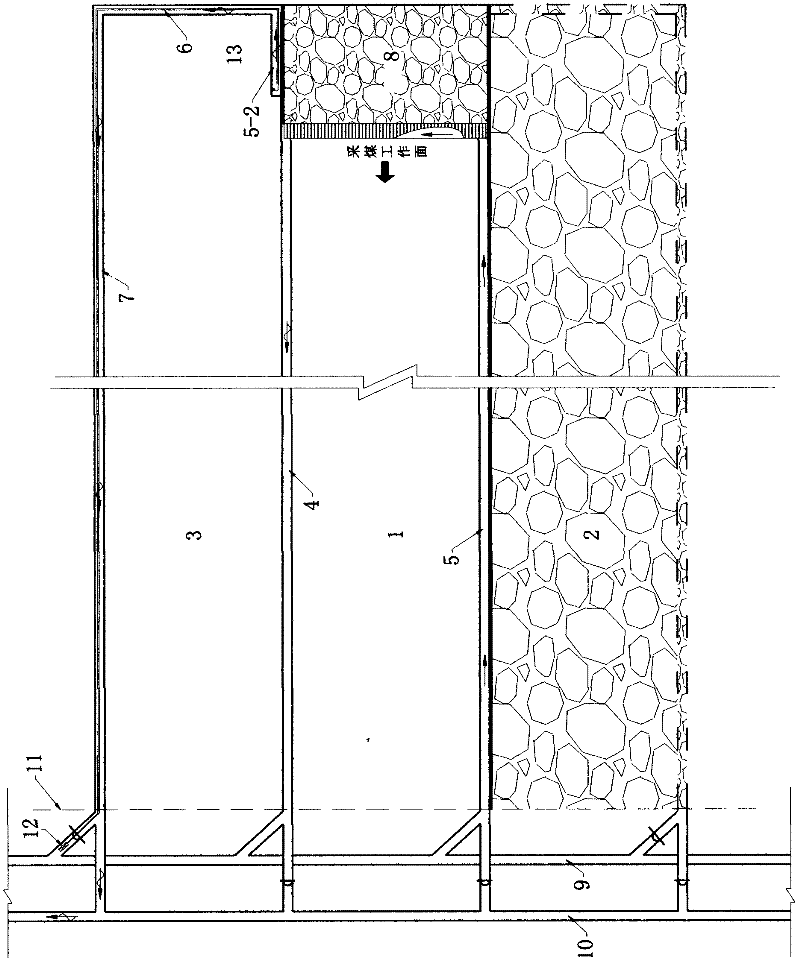

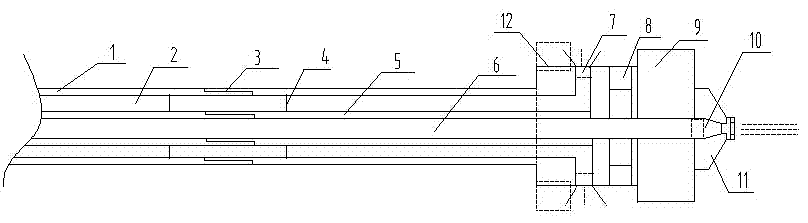

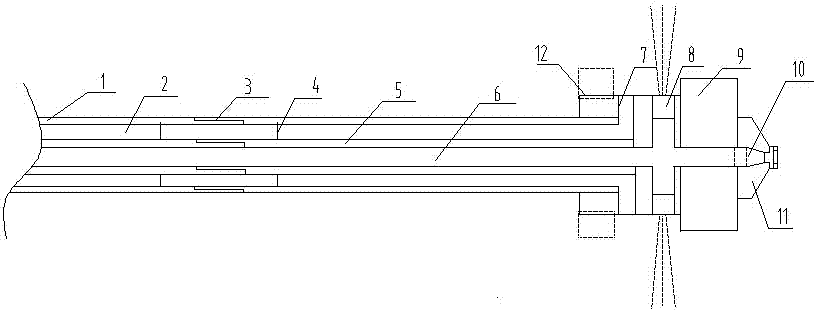

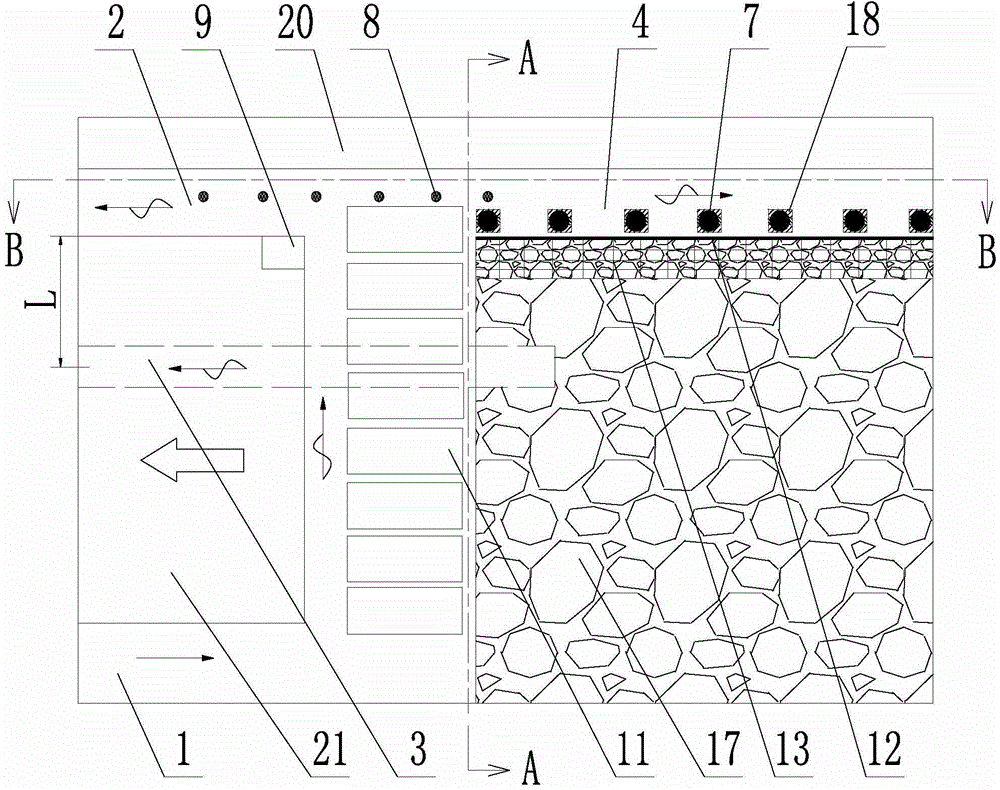

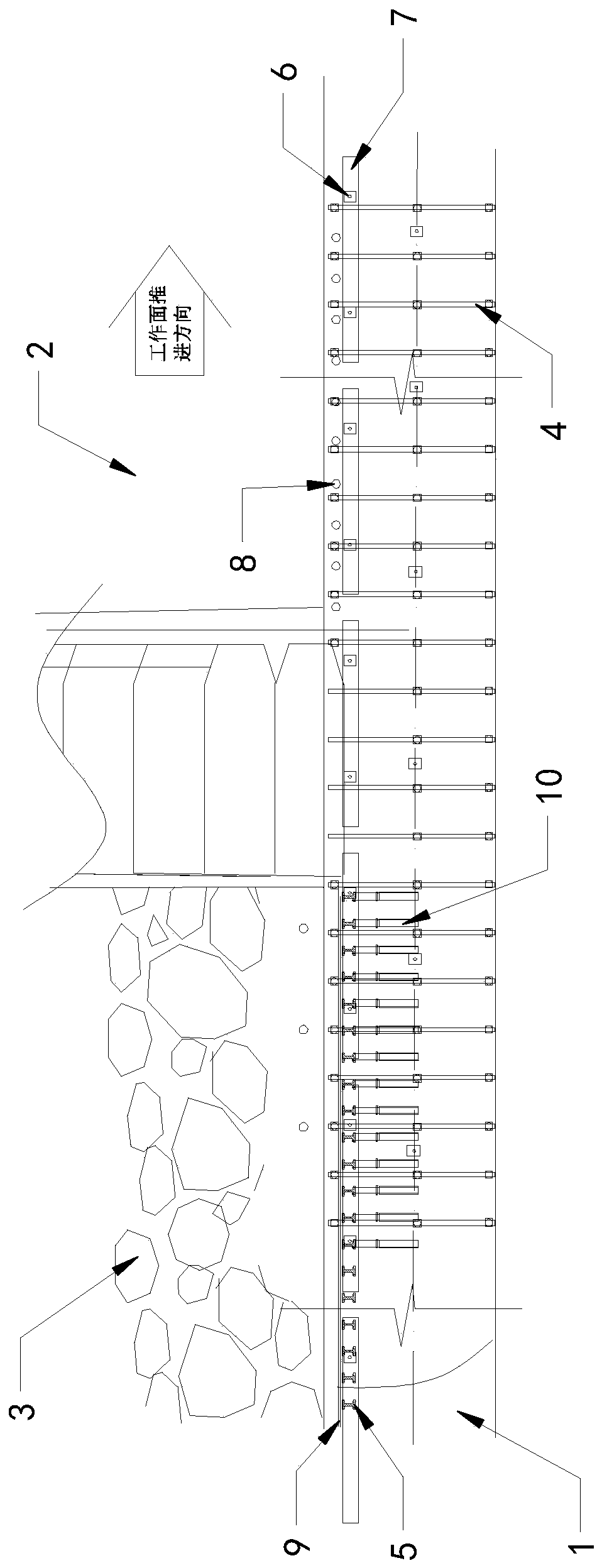

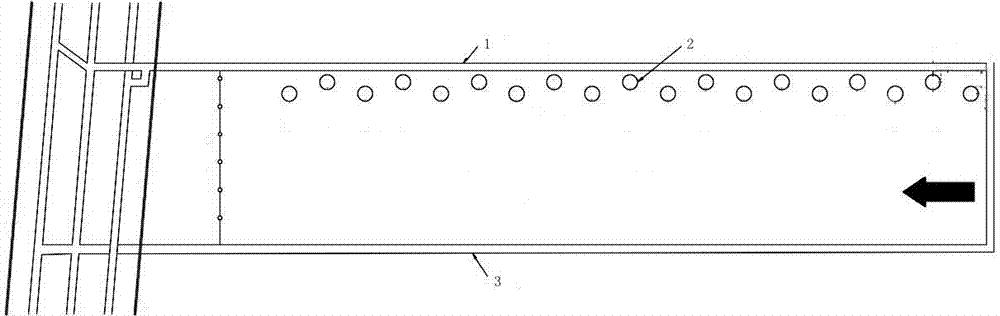

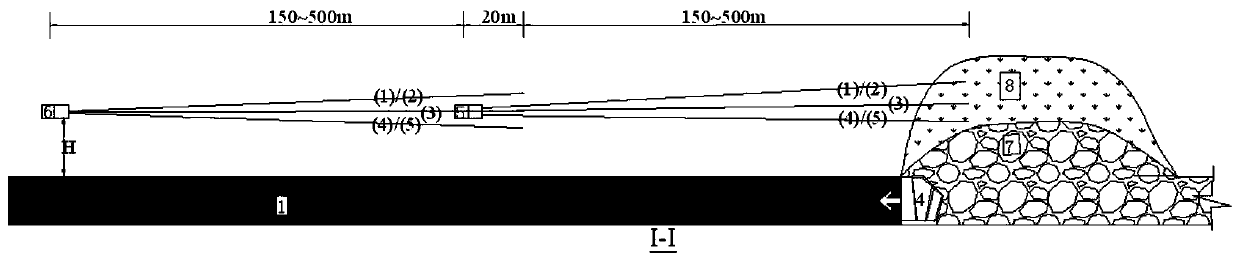

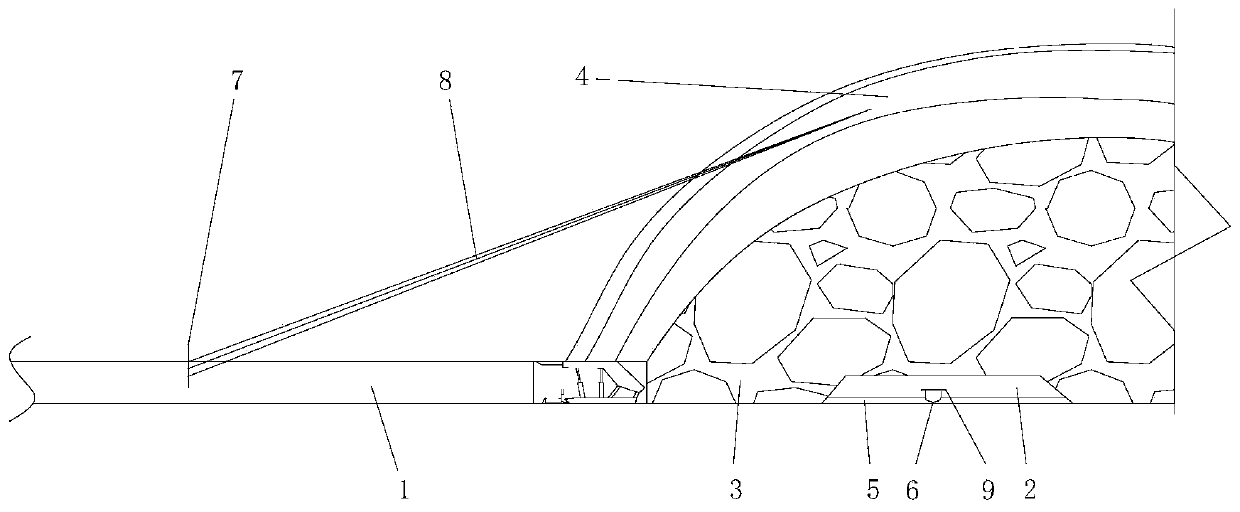

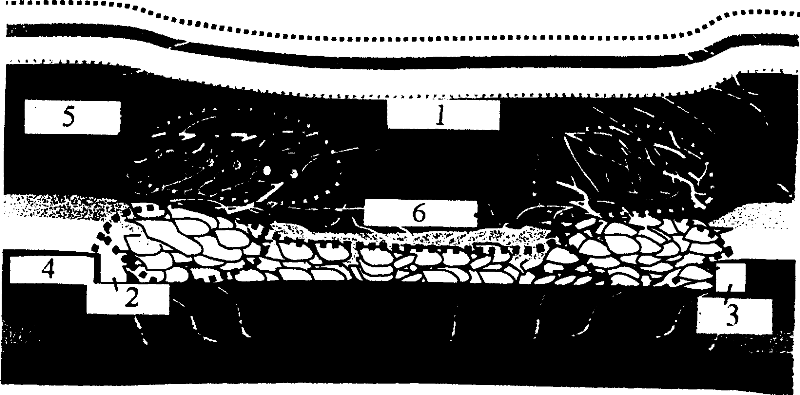

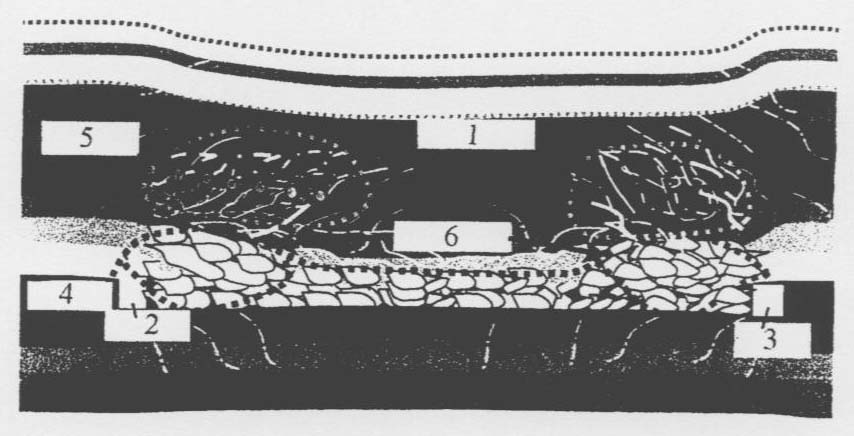

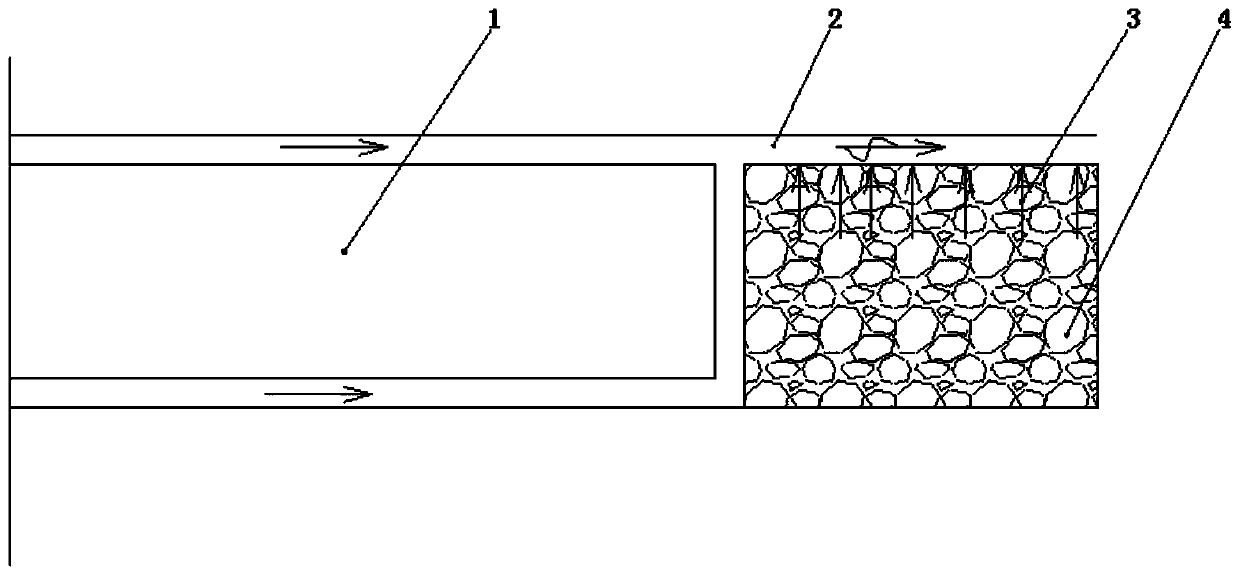

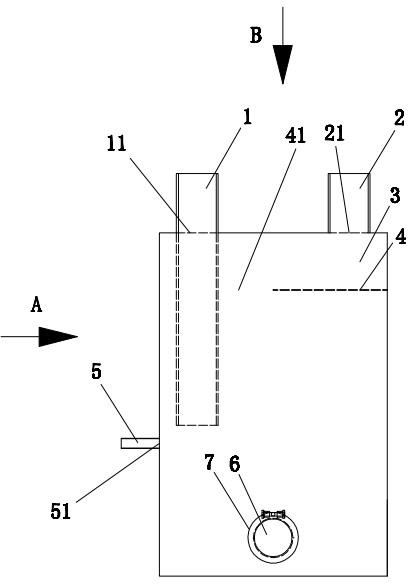

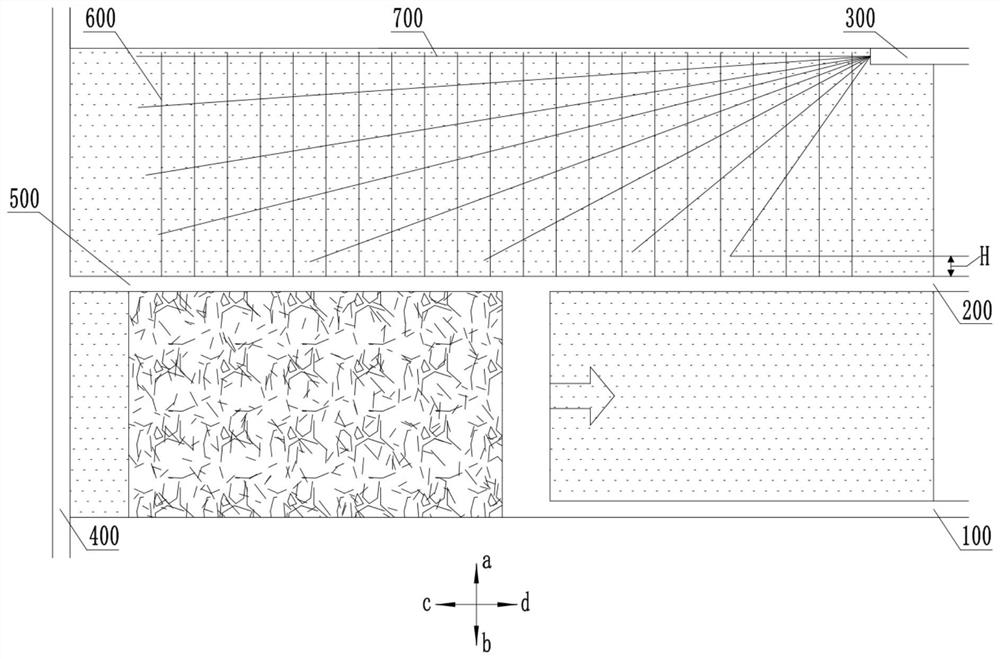

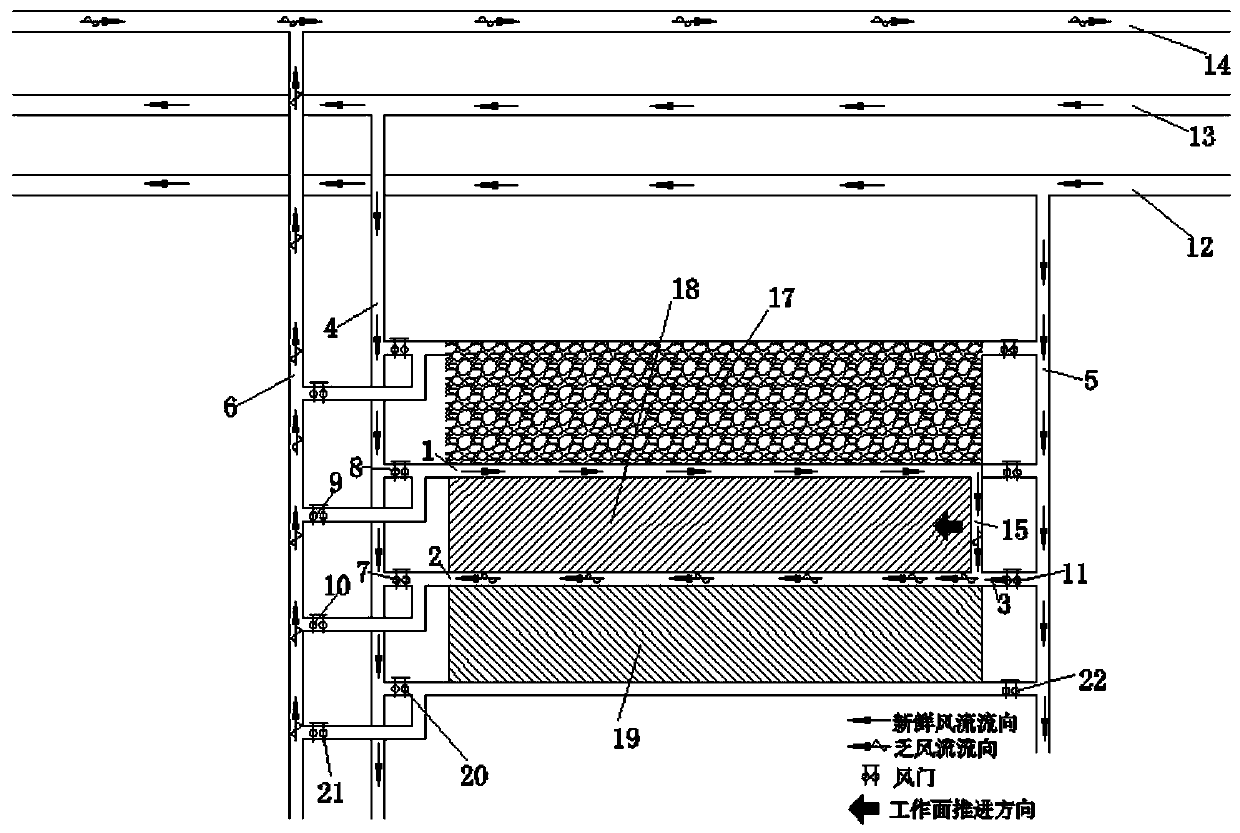

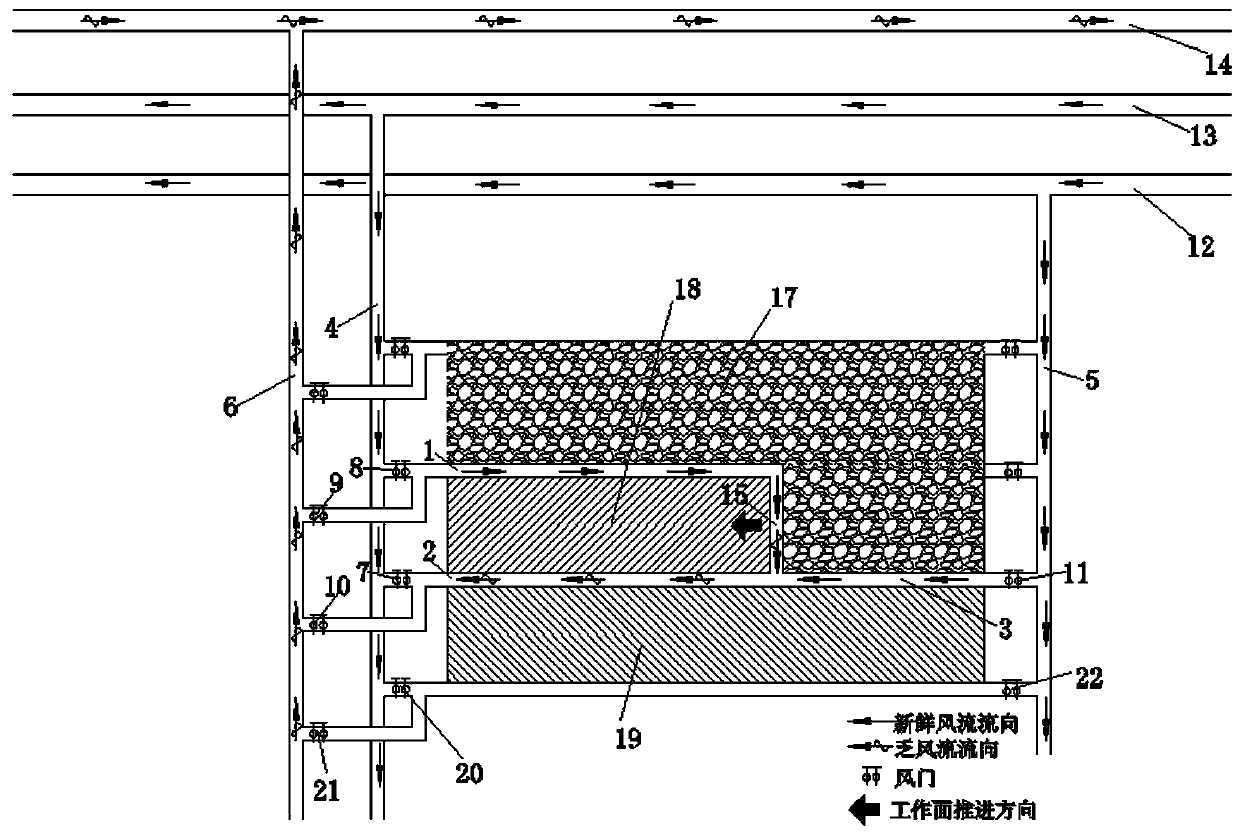

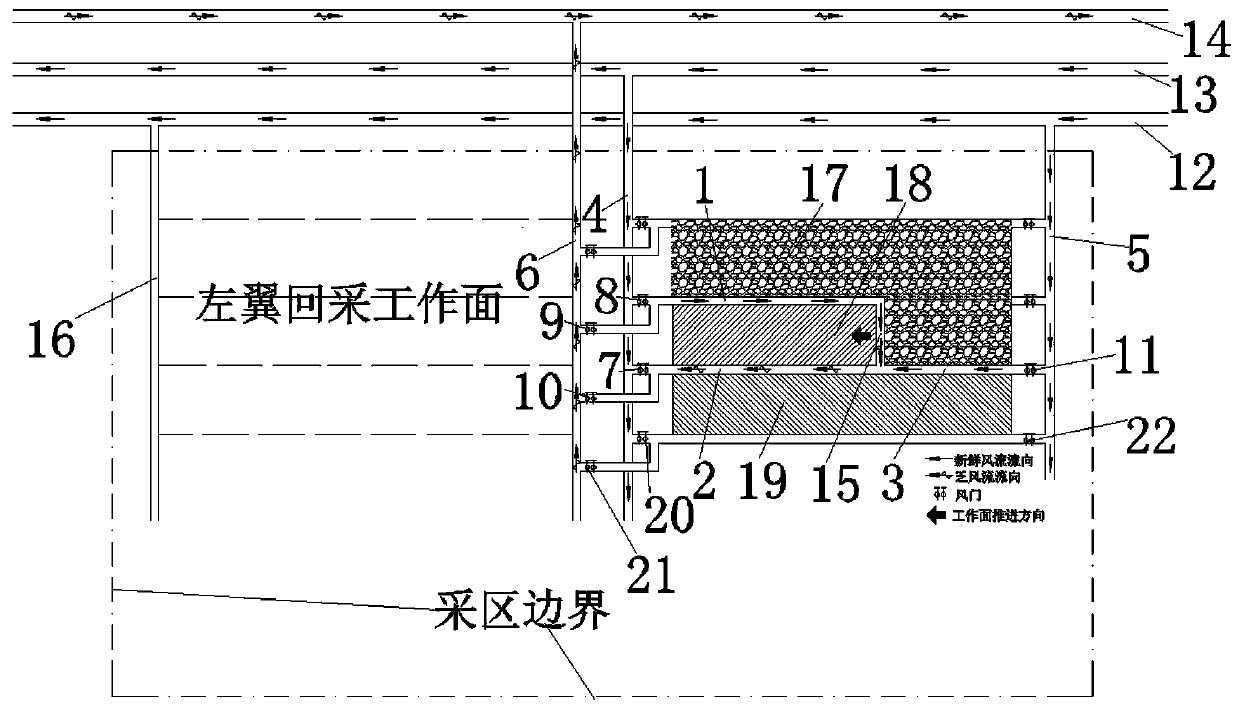

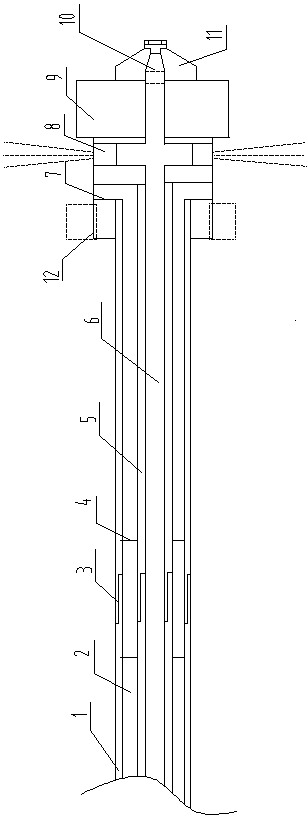

The invention discloses a method for arranging roadways on a coal-pillar-free stope. Particularly, the method comprises the following steps: two roadways are arranged on each working face, one is an excavating roadway, and the other is a gob-side retained or excavated roadway on an upper working face; before a present working face is stopped, a roadway and a cut are excavated in advance on a supersedure working face adjacent to the present working face; the cut is connected with the excavating roadway of the present working face; and the excavating roadway and the cut of the supersedure working face serve as the boundary return airway of the present working face during gob-side roadway retaining, and serve as the construction pathway for the gob-side excavated roadway during gob-side entry driving. Therefore, through the adoption of the method, mining without coal pillars is achieved and a two-in and one-out Y+L type ventilation system is formed. In the method, the excavating roadway and the cut of the supersedure working face serve as the return airway of the present working face and one roadway of the supersedure working face, thereby achieving dual purposes and eliminating the excavating of a roadway; and a pressure peak area is avoided, so that more coal pillars can be extracted, the problem of transfinite methane gas is solved, the excavation tight relationship is relieved, and the method can be widely applied to coal mines, metallurgic mines and other industries.

Owner:王晓利

Method for pumping out gas from mining coal layer roof

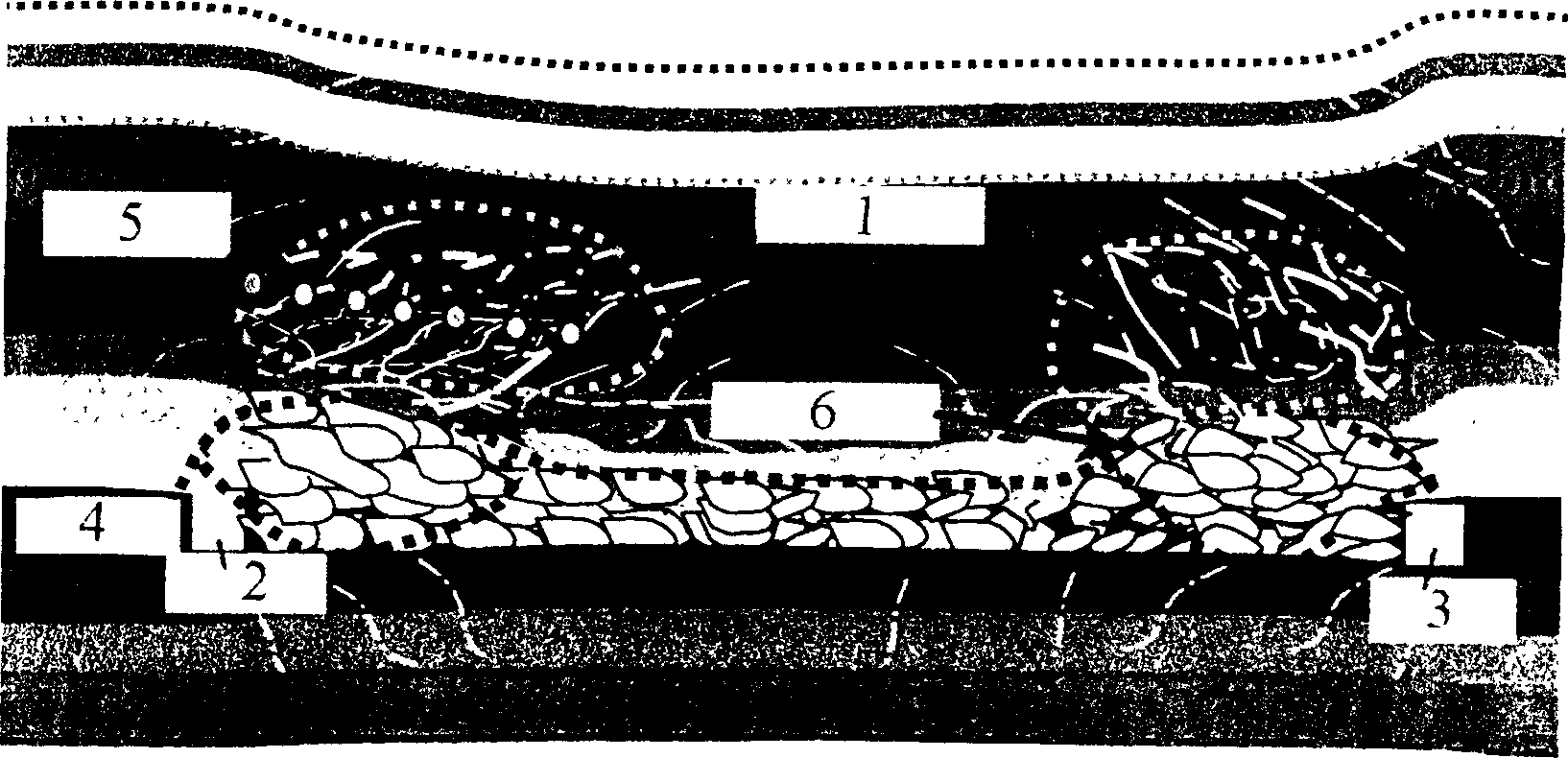

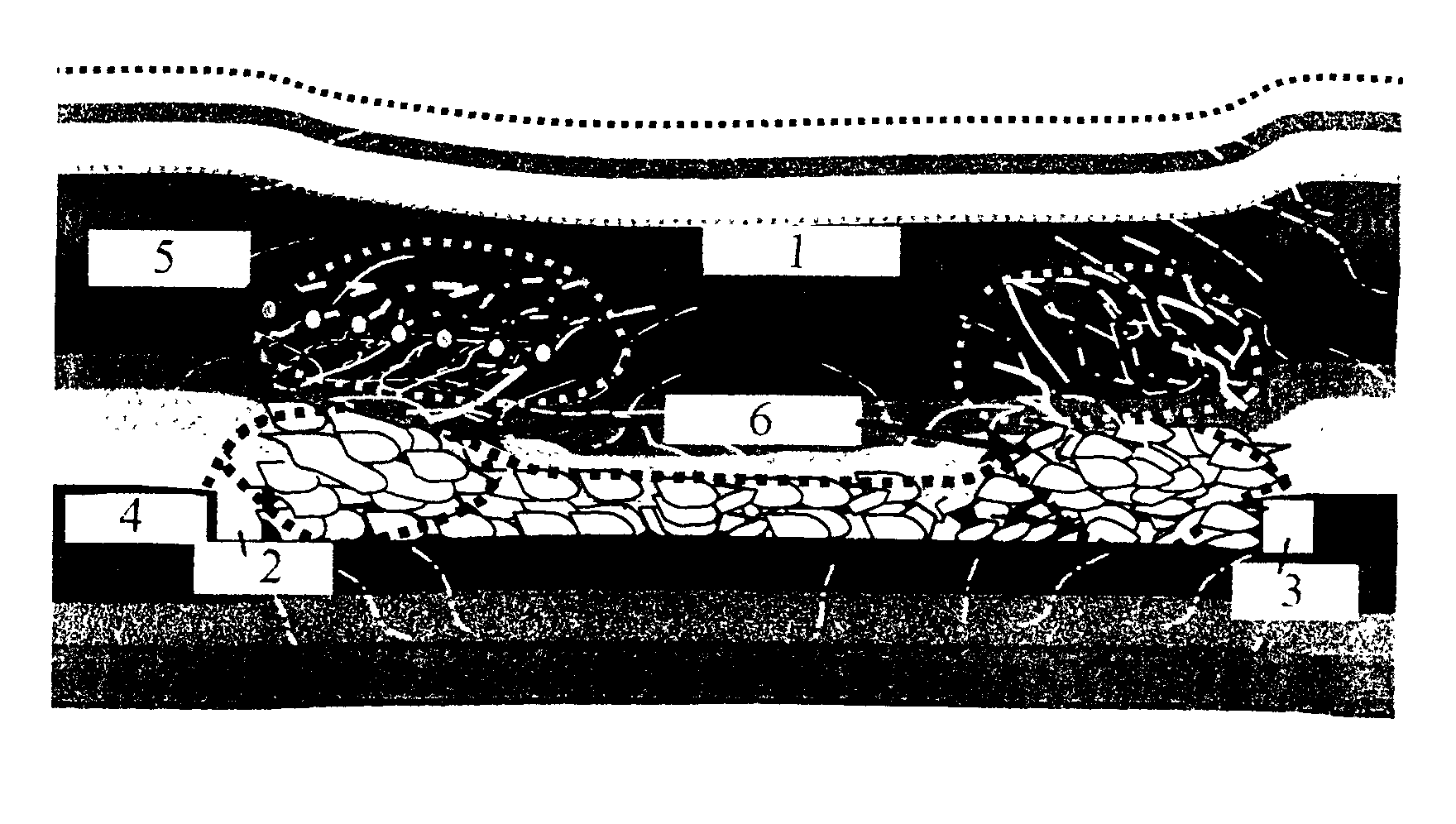

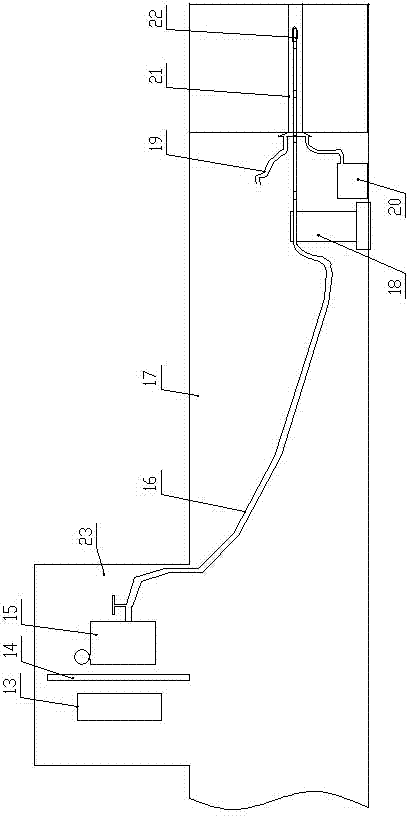

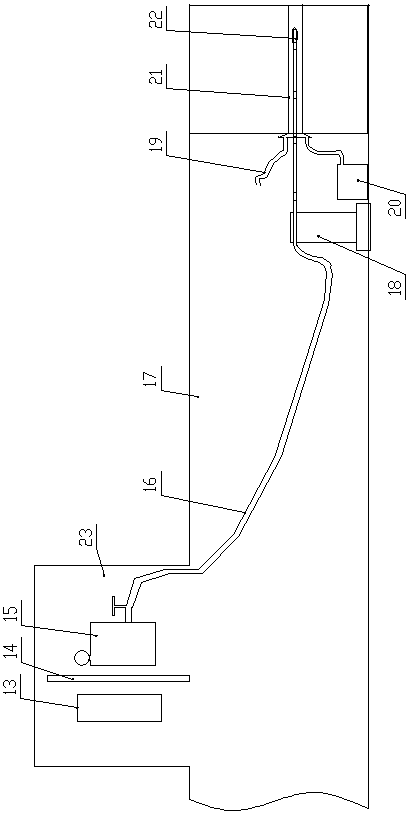

The gas pumping out method during mining cliff features that during mining cliff, the desorbed gas from the mined and released coal layers to the 'annular crack circle' via crack channel formed through mining is pumped via the drilled holes or tunnel in the 'annular crack circle'. The 'annular crack circle' is located in the stratafugic crack band over the stoped out cliff inbreak band near return airway and intake airway in the coal mining face. The present invention solves the problem of overrunning gas in stoping working face to ensure safe production.

Owner:HUAINAN MINING IND GRP +1

Fully-mechanized caving mining process technology with large mining height in super-high seam (14-20m)

ActiveCN101967975AIncrease coal breaking effectIncrease coal discharge spaceUnderground miningSurface miningControl measureCoal mining

The invention provides a coal mining method of fully-mechanized caving mining with large mining height in a super-high seam, a coal caving process, reasonable type of a support, production capacity of equipment, comprehensive control measures of coal wall spalling of working face, a technical route for improving the recovery rate of the fully-mechanized caving face with the large mining height, and feasibility evaluation indexes (thickness of the seam, top coal cavability, coal wall stability and roof pressure strength) of the fully-mechanized caving mining with the large mining height, and further forms a whole set of fully-mechanized caving mining process technology with the large mining height. The coal mining method is that the coal cutting height is 4.2-4.8m; the length of the working face is 200-280m; and the web of a coal mining machine is 0.8-1m. The process technology can increase the coal cutting quantity by 43%, shorten the coal caving time by 9%, relatively reduce the coal caving quantity by 9%, improve the resource recovery rate by 5% and reduce the mining-caving ratio to below 1:3 by increasing the coal cutting height, and can further realize the relatively balanced production of mining and caving of the working face.

Owner:DATONG COAL MINE GRP

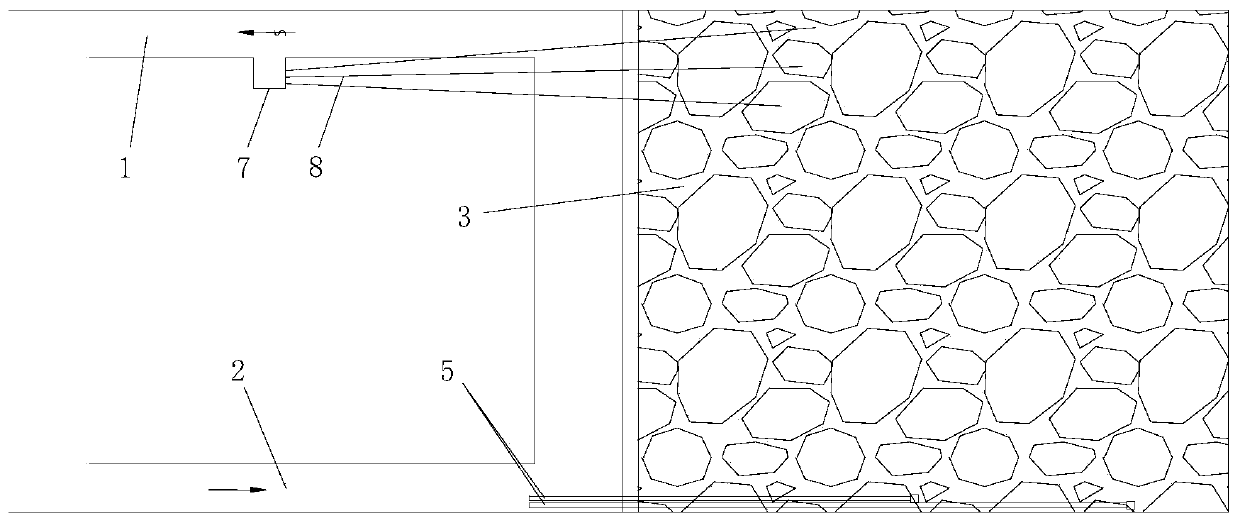

Low-permeability soft coal seam extra-thin layer water jetting exploiting permeability increasing method

InactiveCN104727795AChanges in hardness have a large impactProne to stressFluid removalGas removalSlagRelease time

The invention discloses a low-permeability soft coal seam extra-thin layer water jetting exploiting permeability increasing method. The method includes the following steps that 1 extra-thin layer water jetting exploiting parameters are designed; 2 extra-thin layer water jetting exploiting devices are machined, tested and installed; 3 a water jetting exploiting radius and a corresponding water jetting parameter are measured; 4 slag discharge holes and middle exploiting holes are constructed; 5 water jetting coal mining is started on an extra-thin layer; 6 when the coal mining reaches a designed location, the extra-thin layer water jetting exploiting devices are closed; 7 jetting exploiting drill holes and the slag discharge holes are linked to pumping-releasing pipelines to pump and release; 8 the steps ranging from 5 to 7 are repeated, and next drilling construction and jetting exploiting are conducted; 9 detection is conducted on a extra-thin layer exploiting pressure relief effect. By means of the method, the flow of coal seam hectometer hole drilling gas is increased by times, the pumping and releasing time of the gas is greatly shortened, the pumping and releasing radius is increased by times, the well drilling construction quantity is reduced, the gas overrunning probability is greatly reduced in the tunneling period and stoping period, and valuable time and safety guarantee are provided for the coal mine safety-efficient stoping and tunneling.

Owner:HENAN POLYTECHNIC UNIV

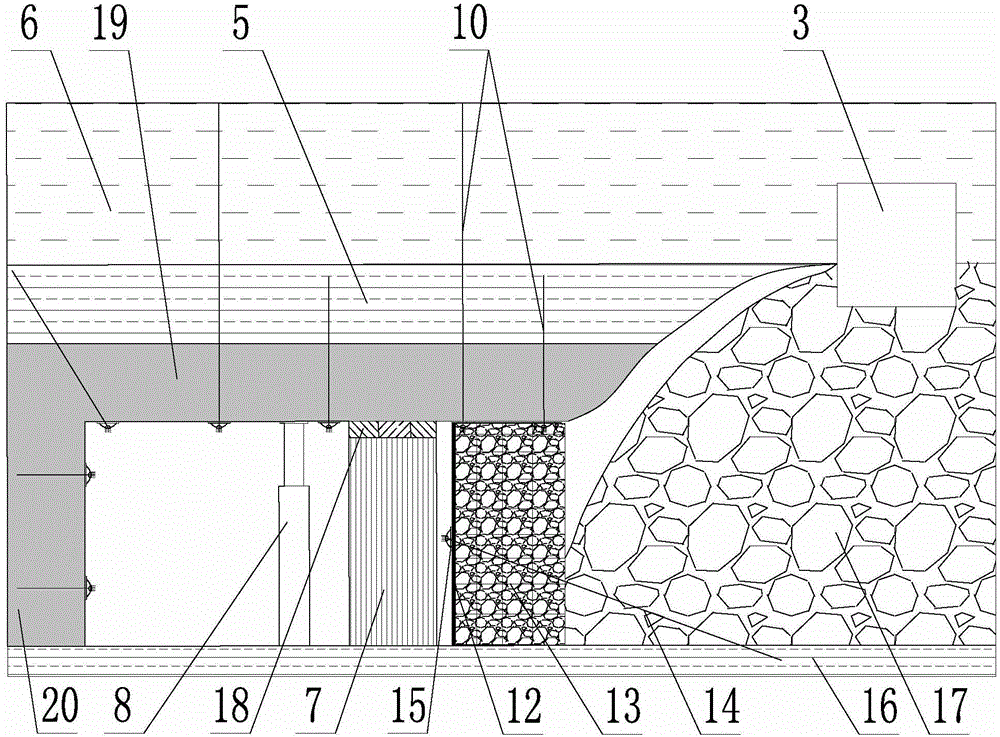

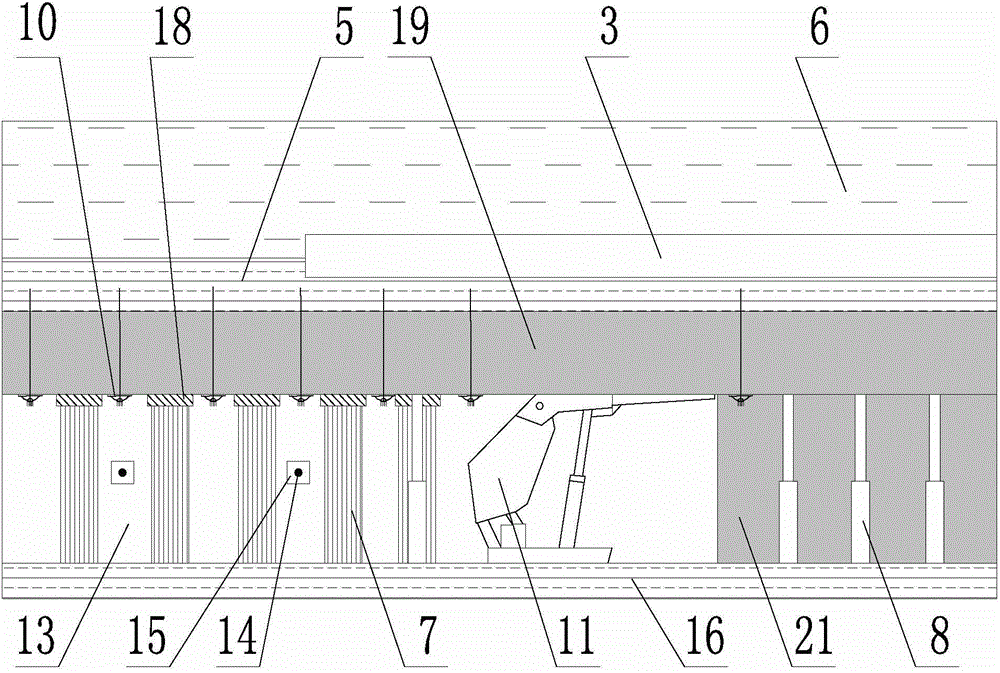

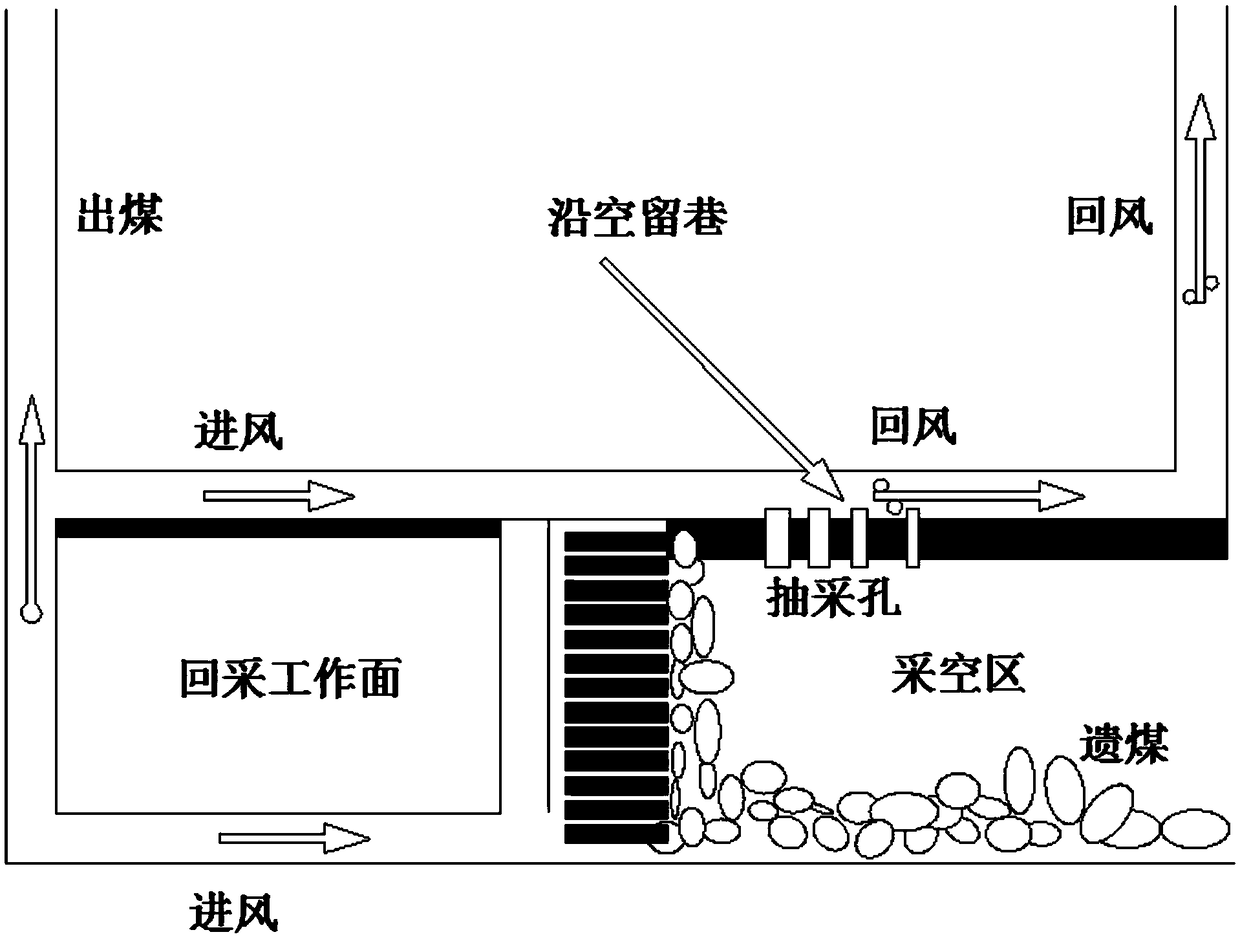

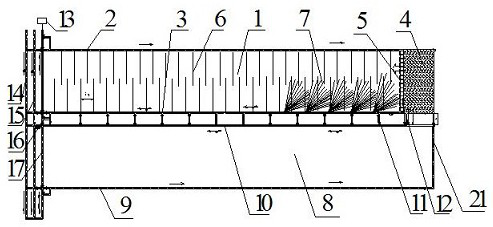

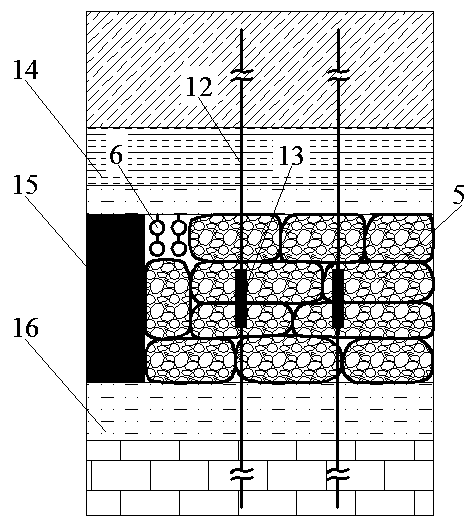

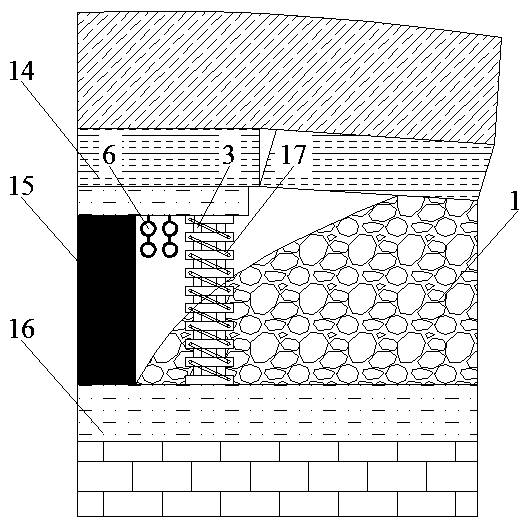

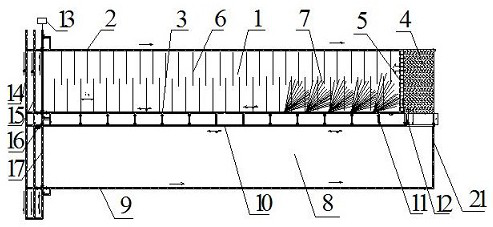

Fully mechanized caving face gob-side entry retaining process and ventilating method

InactiveCN104481568ASolve the overrun problemGuaranteed mining rateUnderground chambersTunnel/mines ventillationRebarCoal pillar

The invention relates to a fully mechanized caving face gob-side entry retaining process and a ventilating method, and belongs to the technical field of mine supports and ventilating security. The process is applied to a high-gas thick-seam large-section roadway with poor conditions; an air inlet way, an air return way, a remained gob-side entry and a gas discharge way form an Y-I ventilating mode, and a problem of gas concentration exceeding limitation caused by corner methane accumulation on a coal mining working face is solved; the air return way behind a fully mechanized caving face is retained to serve as the gob-side entry, and gob-side entry retaining operation is performed, so that the mining without coal pillars is achieved, and the mining coefficient is ensured; a pier column serves as side way support, so that the side way supporting strength is improved; gangue is used for establishing an additional gangue wall on the outer side of the pier column of the side way support, so that the pressure on the pier column can be obviously reduced, and the impact of the roof fallen gangue in a gob on the pier column is avoided; and a layer of concrete is coated on a reinforcing steel bar net, so that air leakage of the gob is effectively avoided. The gob-side entry retaining process and the ventilating method are easy to implement and promote, and has excellent economic values.

Owner:LIAONING TECHNICAL UNIVERSITY

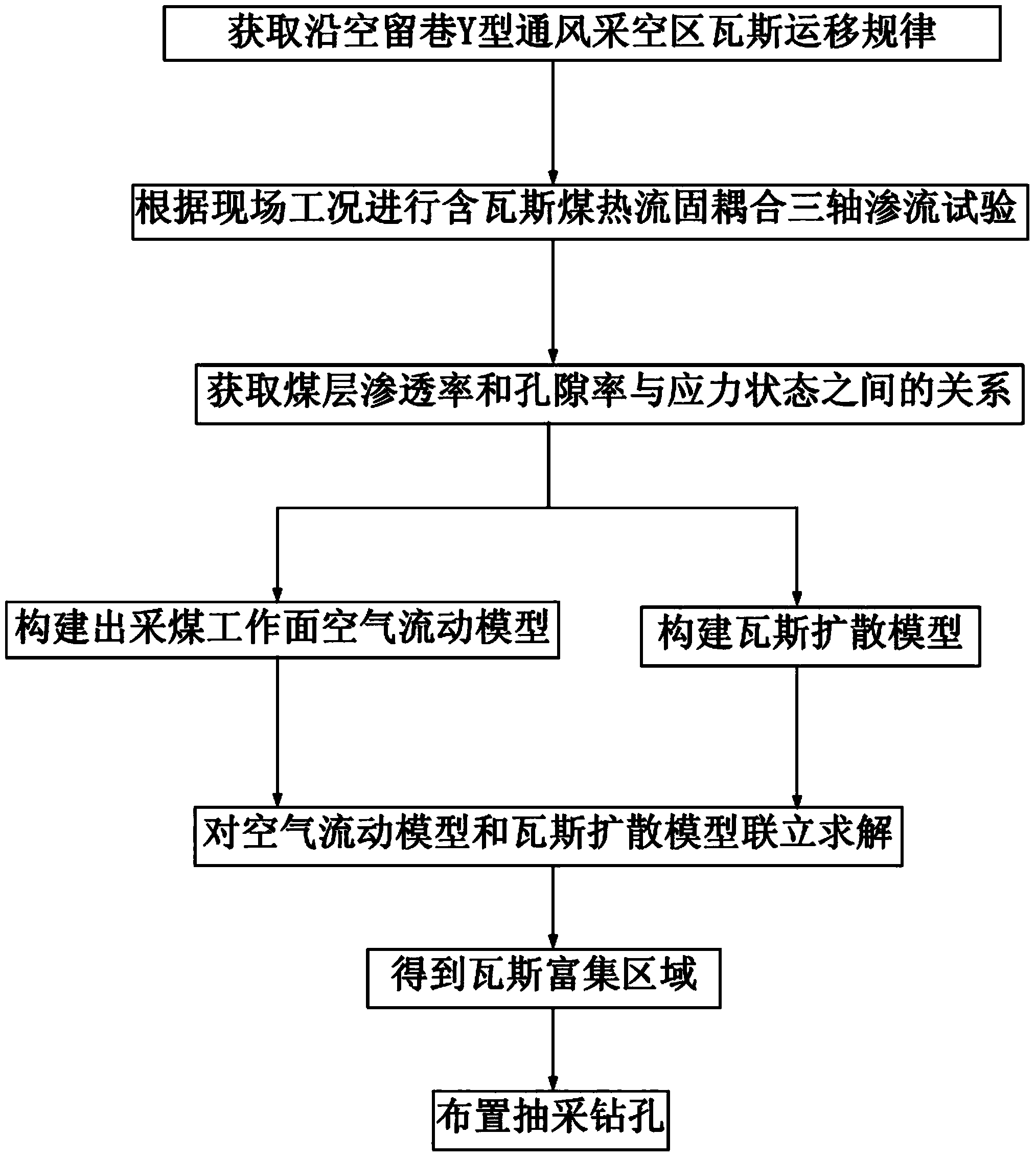

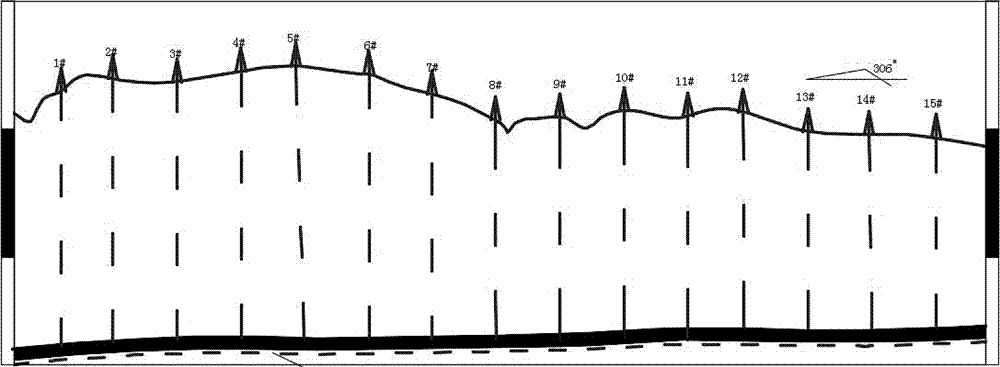

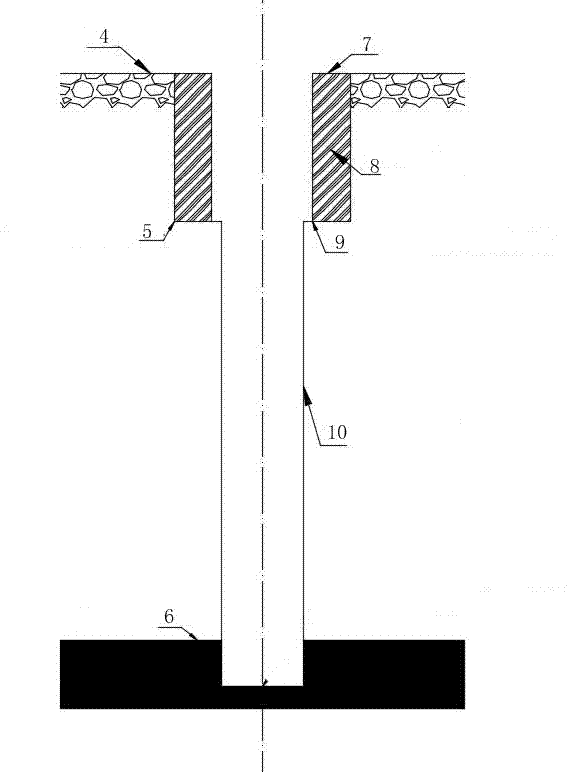

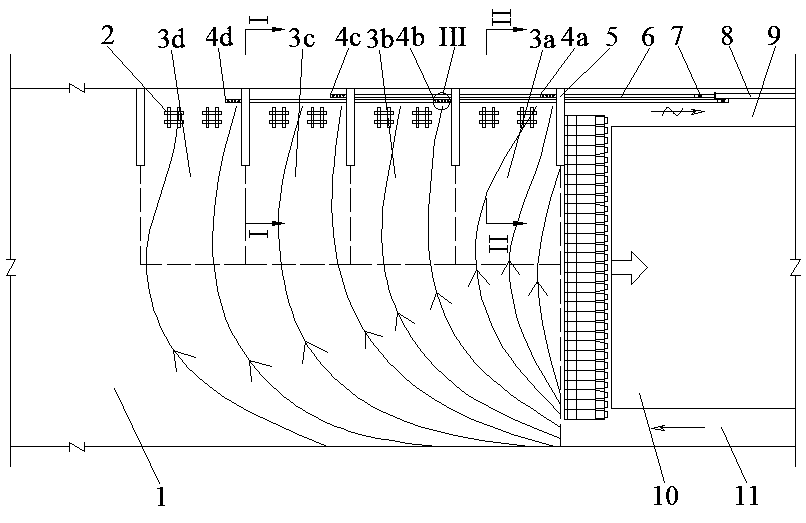

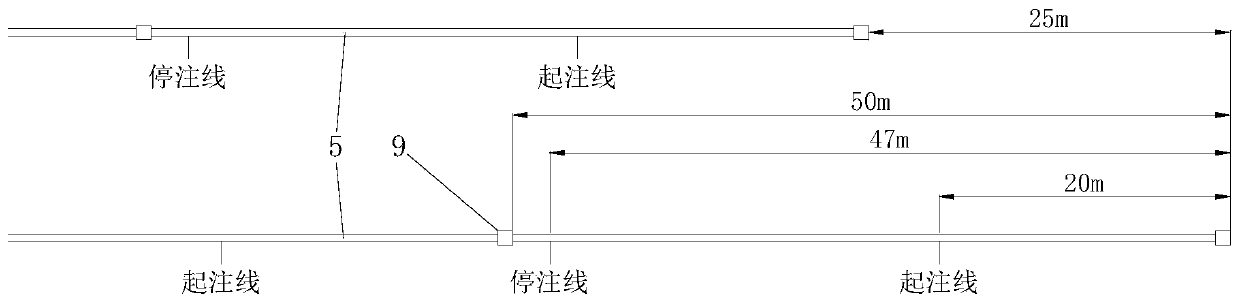

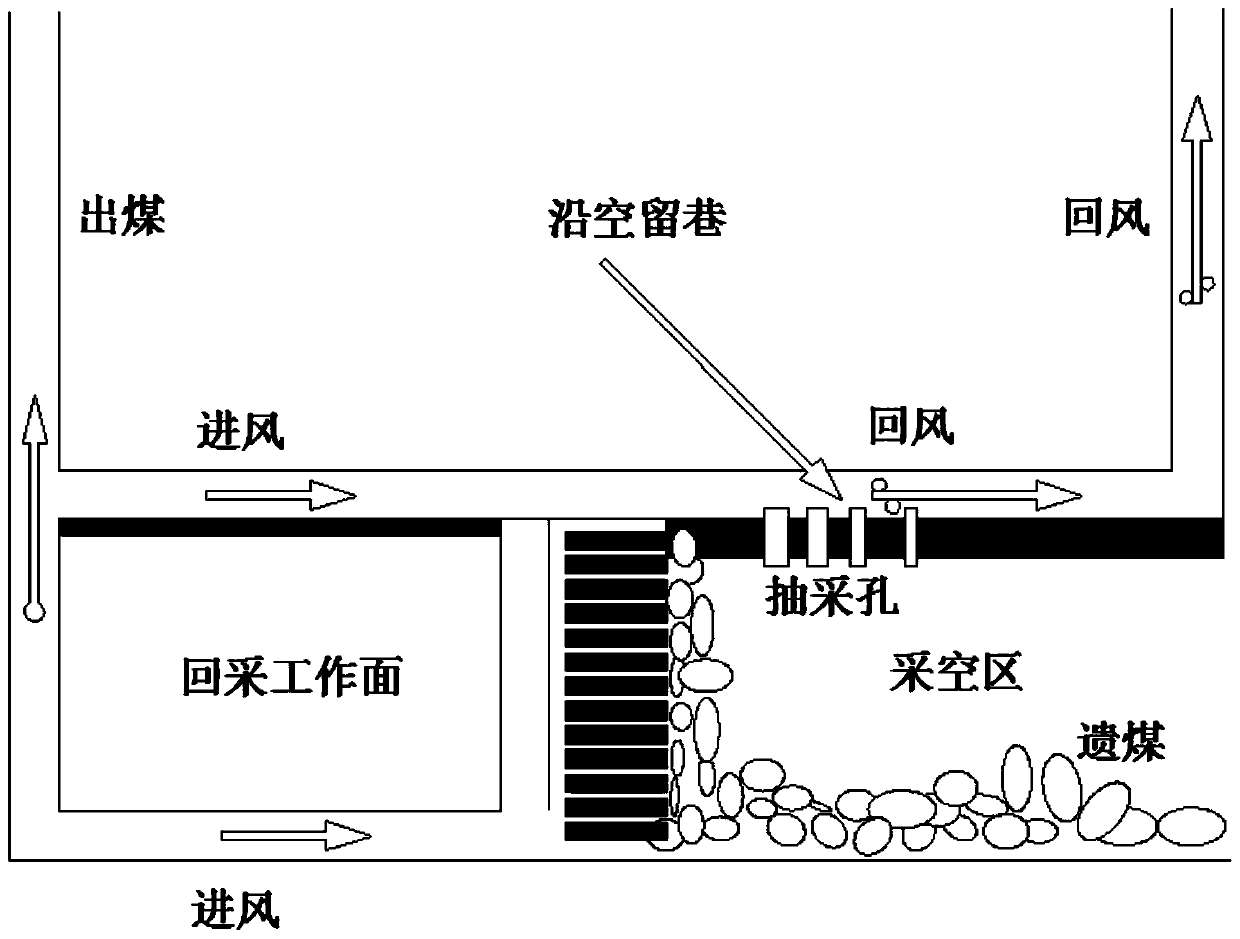

Coal pillar-free exploitation Y-shaped venting goaf drilling hole location method

InactiveCN103821554ASolve the problem of accurate positioning of drilling holesSolve precise positioningFluid removalGas removalCoal measuresCoal pillar

The invention discloses a coal pillar-free exploitation Y-shaped venting goaf drilling hole location method and belongs to the field of gas extraction. Drilling hole location is performed according to a gob-side entry retaining Y-shaped goaf gas moving law and a gas enrichment area, so the gas extraction effect is good, an extraction drilling hole penetrates through a caving zone and a fault zone in sequence to reach the lower part of a curved sinking zone, the problem of accurate positioning of the gas extraction holes of overlaying strata structures of different coal measure stratas is solved, and the gas extraction effects are ensured. As massive pressure-relieving gas and the goaf gas are extracted, the problems of upper corner gas ultralimit and return air gas ultralimit are fundamentally solved, and the safety production of a mine is ensured. Meanwhile, under the premise of ensuring the extraction effects, the drilling hole location method is strongly targeted at the gas enrich area, thus reducing the extraction hole number and enlarging the extraction hole location interval; the method has the advantages of small work amount and economy.

Owner:CHONGQING UNIV

Coal mine gas extraction method

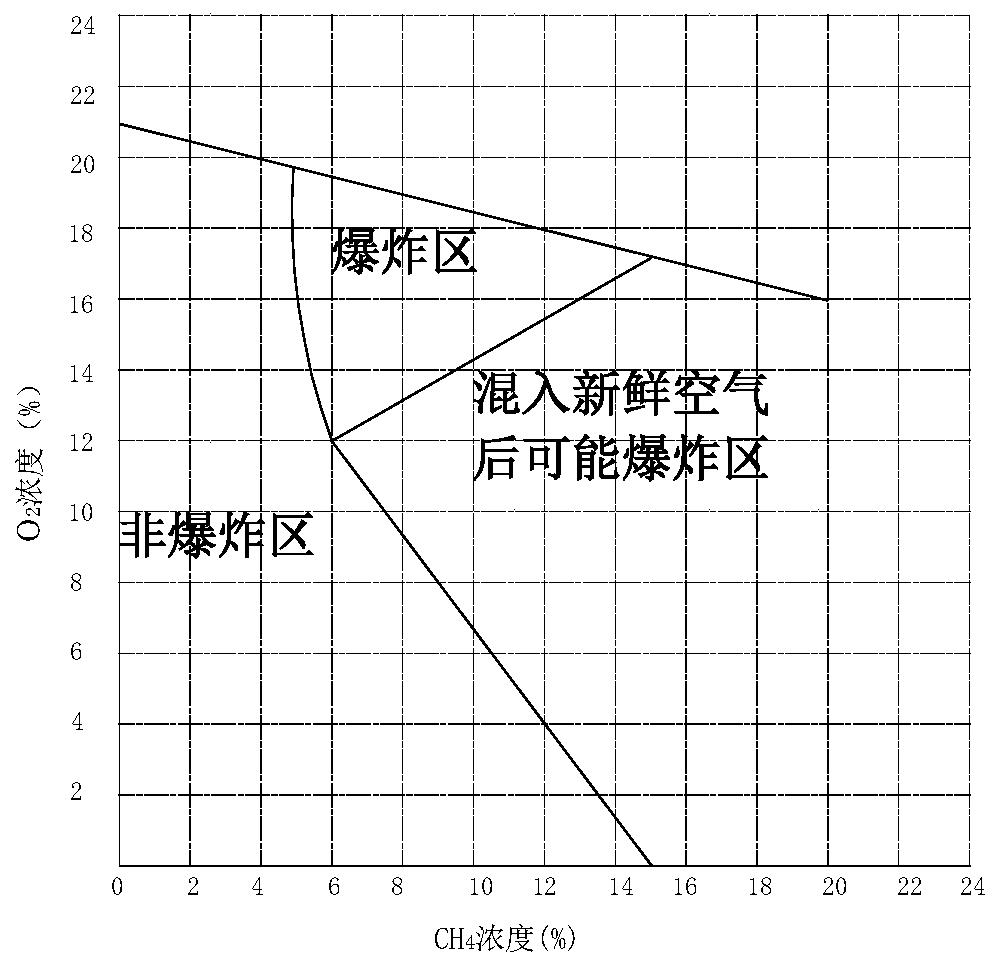

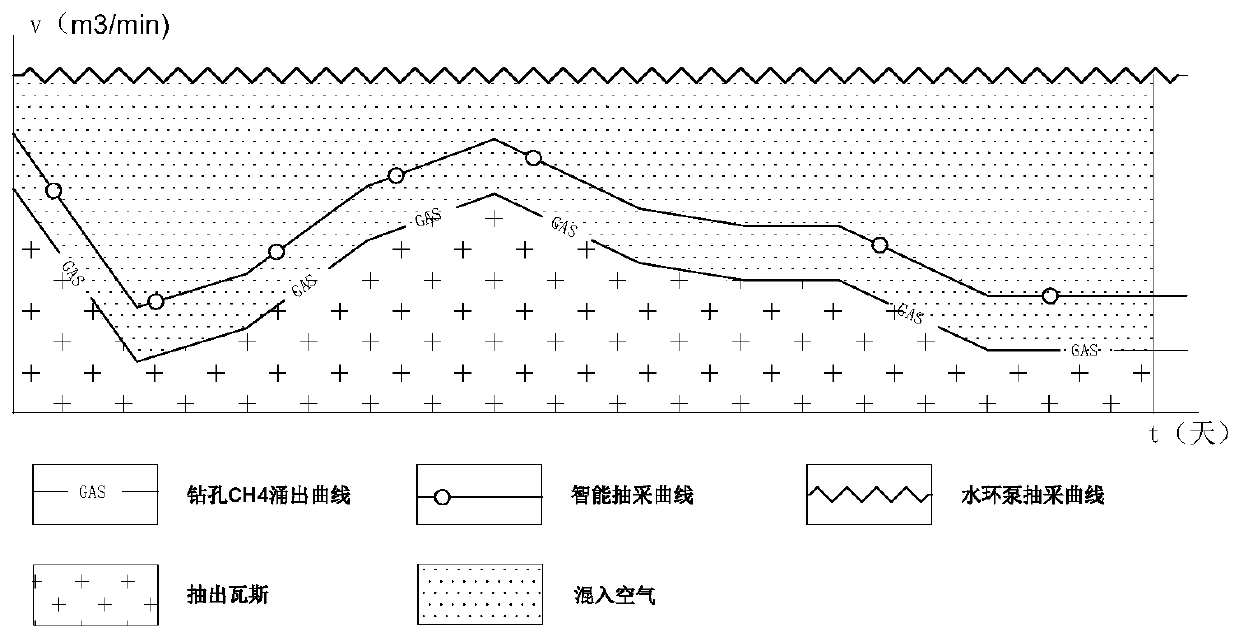

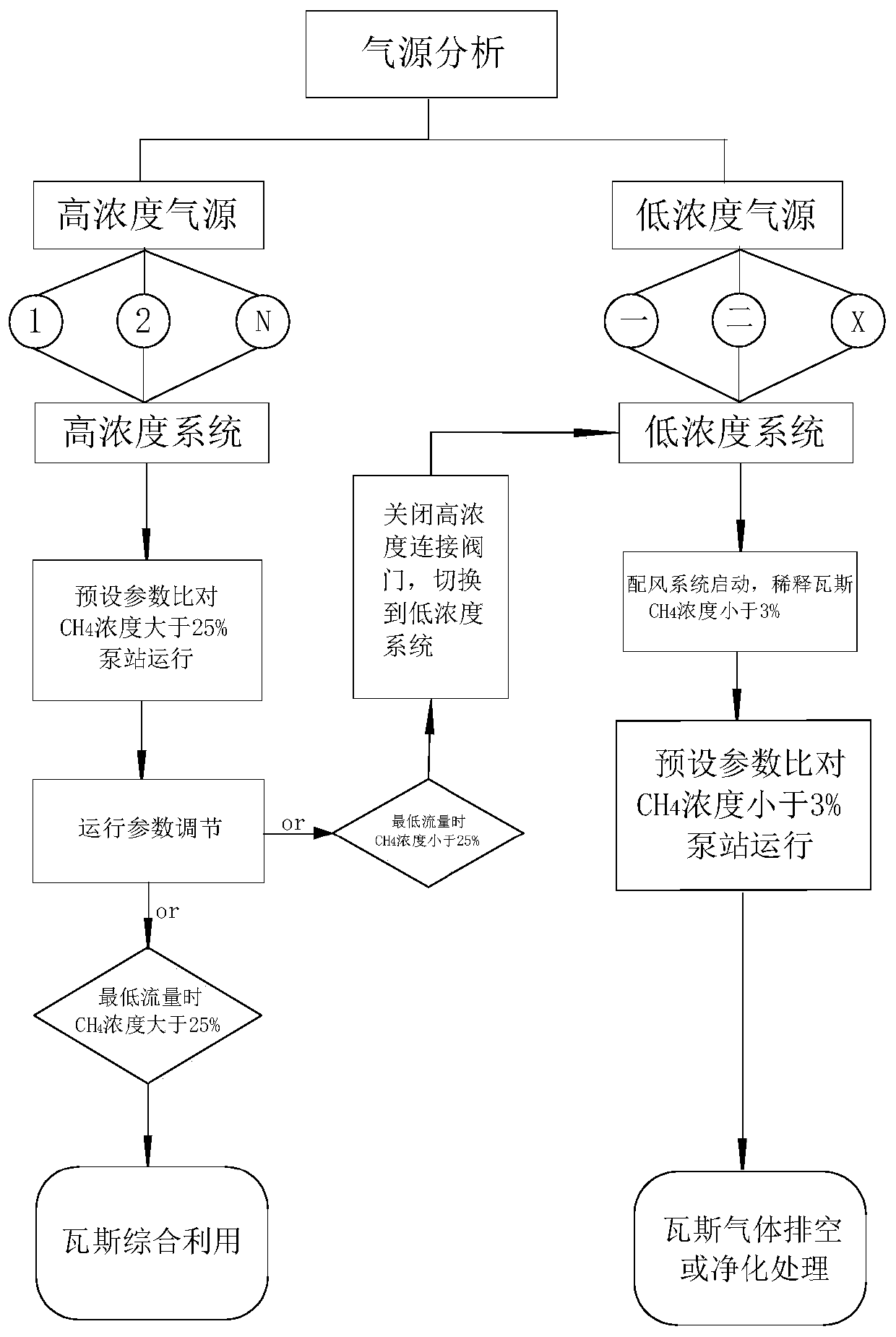

InactiveCN109869182AEnsure safetyEmission reductionMining devicesGas removalIntrinsic safetyHigh concentration

The invention discloses a coal mine gas extraction method. The coal mine gas extraction method comprises the following steps that a gas source is divided into a high concentration gas source and a lowconcentration gas source, the gas concentration in the high concentration gas source is larger than or equal to 25%, and the gas concentration in the low concentration gas source is less than 25%; ahigh concentration gas extraction system is used for extracting the high concentration gas source, and when the gas concentration is less than 25%, extraction parameters are adjusted to increase the gas concentration; when the gas concentration cannot be increased to be larger than or equal to 25%, a low concentration gas extraction system is used for extracting, the low concentration gas extraction system is adopted to extract the low concentration gas source and the high concentration gas source which does not meet the high concentration gas extraction conditions; and meanwhile, an air distribution system is started to dilute the gas concentration to be less than 3%. According to the coal mine gas extraction method, the purpose is to provide the coal mine gas extraction method, the gas concentration serves as the central control parameters, the high concentration extraction system and the low concentration extraction system are adopted to replace a traditional high negative pressureextraction system and a traditional low negative pressure extraction system, the extraction gas concentration is avoided being located in an explosion zone, and the intrinsic safety of the gas extraction in coal mine is realized.

Owner:三河路矿九鼎科技有限公司

Construction process of gob side roadway protection in medium-thickness coal seam coal face

InactiveCN110439560AReduce stress concentrationEnsure safetyUnderground chambersUnderground miningShotcreteShaped beam

The invention relates to the technical field of coal mining, and provides a construction process of gob side roadway protection in a medium-thickness coal seam coal face. The construction process comprises the steps that a single hydraulic prop is supported in a reserved roadway to be matched with an I-shaped beam, and an anchor cable is erected to be matched with a channel steel protection roof;a presplitting blasting hole is formed in the roof; a single hydraulic prop is supported at the fork of the reserved roadway and the coal face to be matched with the I-shaped beam; the I-shaped beam is erected in the lagging part of the coal face, a steel bar mesh and a metal mesh are sequentially paved along the roadway trend, then the single hydraulic prop is supported to be matched with the I-shaped beam, and then a diagonal prop is supported to strengthen the support of the I-shaped beam; outside the lagging area of the coal face, the single hydraulic prop is retracted; the roadway is treated with shotcrete in full section; and a grouting pipe is pre-embedded under the roof of the coal face for grouting. According to the construction process, the technical effects that the resource recovery rate can be increased, the production cost is saved, the impact on the dynamic pressure of the adjacent roadway is reduced, the secondary maintenance amount of the roadway is decreased, and thelabor intensity of employees is lowered are achieved.

Owner:SICHUAN HUAYINGSHAN LONGTAN COAL

High-yield and high-efficiency working face gas ground mining method of low gas mine

ActiveCN107503789AGive full play to high-efficiency extractionIncrease productivityFluid removalGas removalWell drillingCoal mine methane

The invention belongs to the technical field of coal-mine gas treatment, and particularly relates to a high-yield and high-efficiency working face gas ground mining method of a low gas mine. The problems that a coal seam is large in breathability coefficient and low in gas, a large amount of gas gushes out of a mine, a conventional underground gas mining mode has certain limit, the construction difficulty is large, the cycle is long, and the large joint pressure of digging and mining the mine is caused are solved. The method specifically comprises the following steps of 1, laying out a mining well; 2, drilling the ground, wherein (1), in primary drilling, a phi 425 mm rock bit is adopted, (2), in secondary drilling, a phi 311.1 mm drill is adopted to be drilled into a coal seam, (3), after drilling is completed, as coal mining of the working face is carried forward, and during communication between fissure zones formed in coal mining and the ground mining well, a ground mobile pump station is adopted to begin negative pressure drainage, and (4), after coal mining is conducted, a goaf is formed, and drainage continues through drilling. The method gives full play to efficient mining and short construction period of the mining mine, coal-mine gas is treated, and the production efficiency of the coal mine is improved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

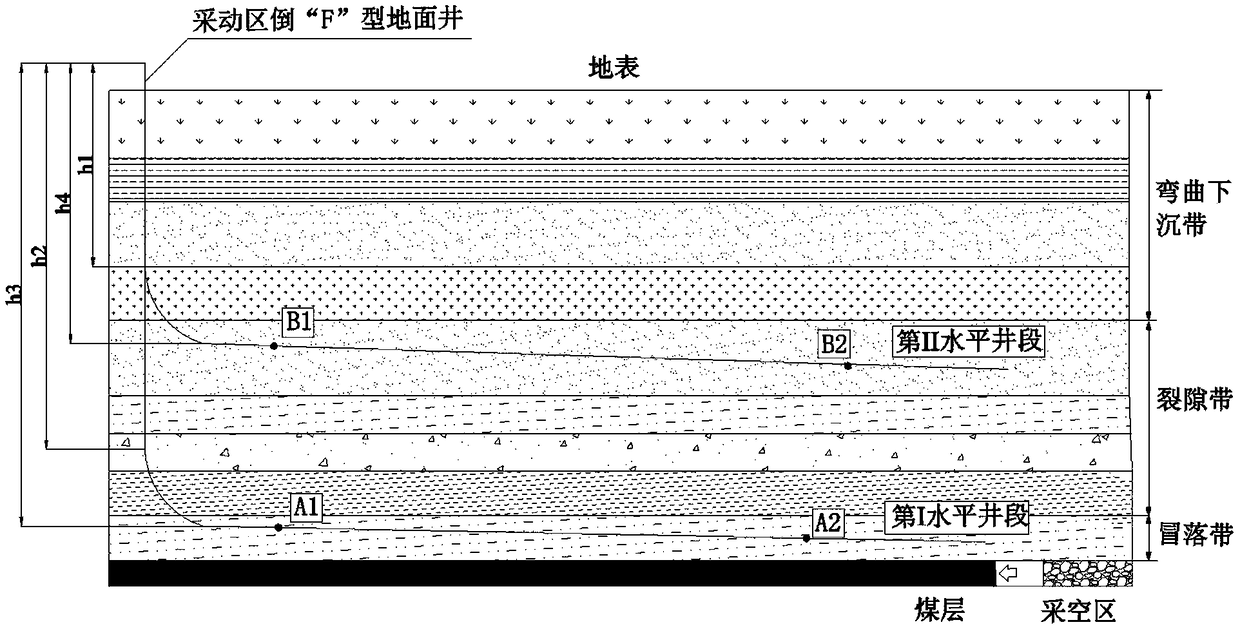

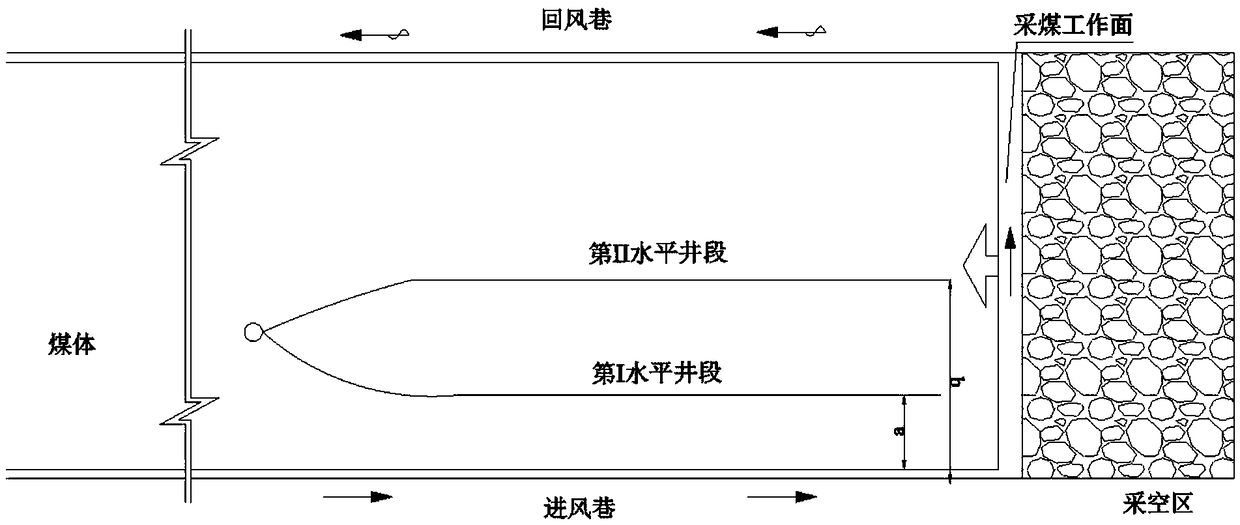

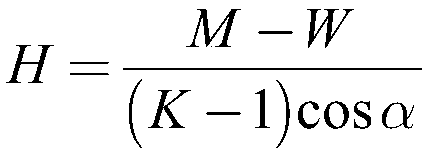

Method for gas resourceextractionof reversed F-shaped ground well in mining area

The invention relates to a method for gas resourceextraction of a reversed F-shaped ground well in a mining area, and belongs to the technical field of coal mine gas extraction. According to the method for extracting gas resourcesin a goaf, the problem that gas is transfinite on a coal face, an upper corner and a return airway is solved. The method mainly comprises the steps that (1) layer position of horizontal well section of the reversed ''F''-shaped ground well in the mining area is determined; (2) the plane position of the horizontal well section of the reversed ''F''-shaped ground well in the mining area is determined; (3) the drilling well completion technology of the reversed ''F''-shaped ground well in the mining area is carried out; and (4) gas of the reversed ''F''-shaped groundwell in the mining area is safely extracted and controlled. Therefore, the complete method for gas resourceextraction of the reversed ''F''-shaped ground well in the mining area can be formed, and the safety of gas in coal face and extraction gas resources in the goaf can be effectively ensured.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

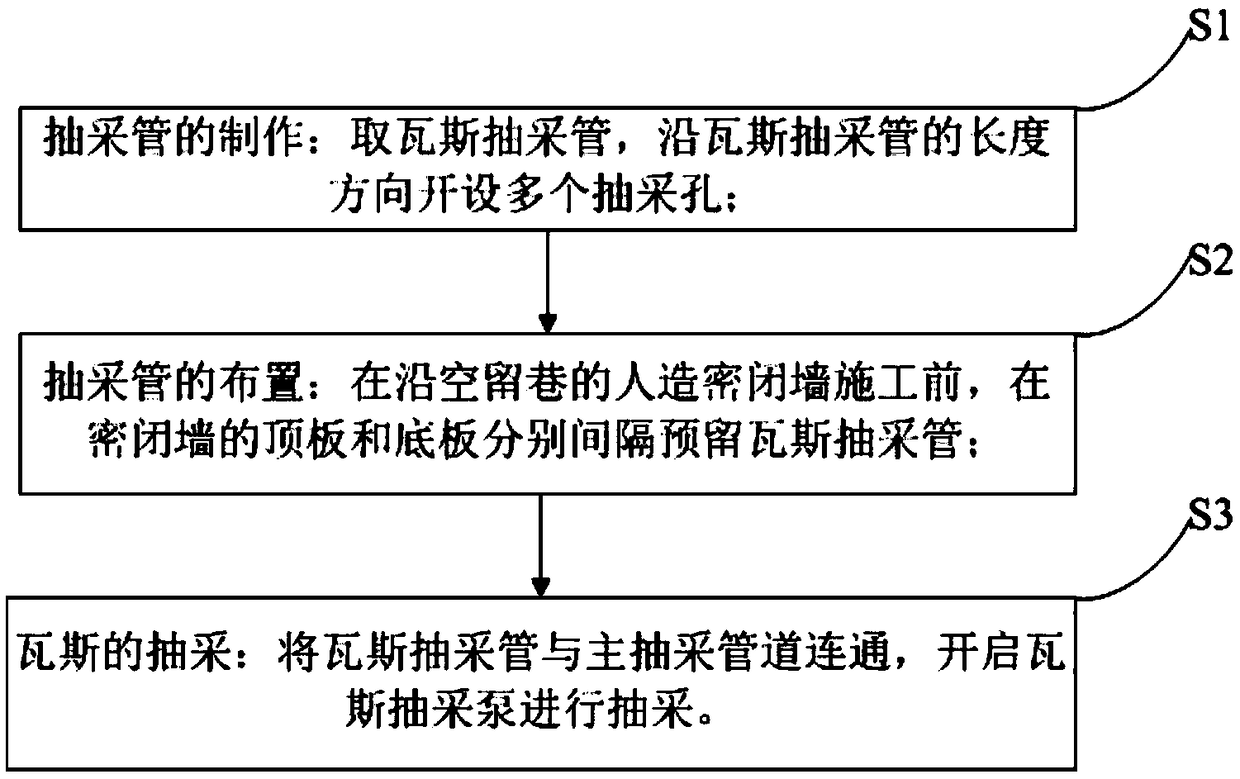

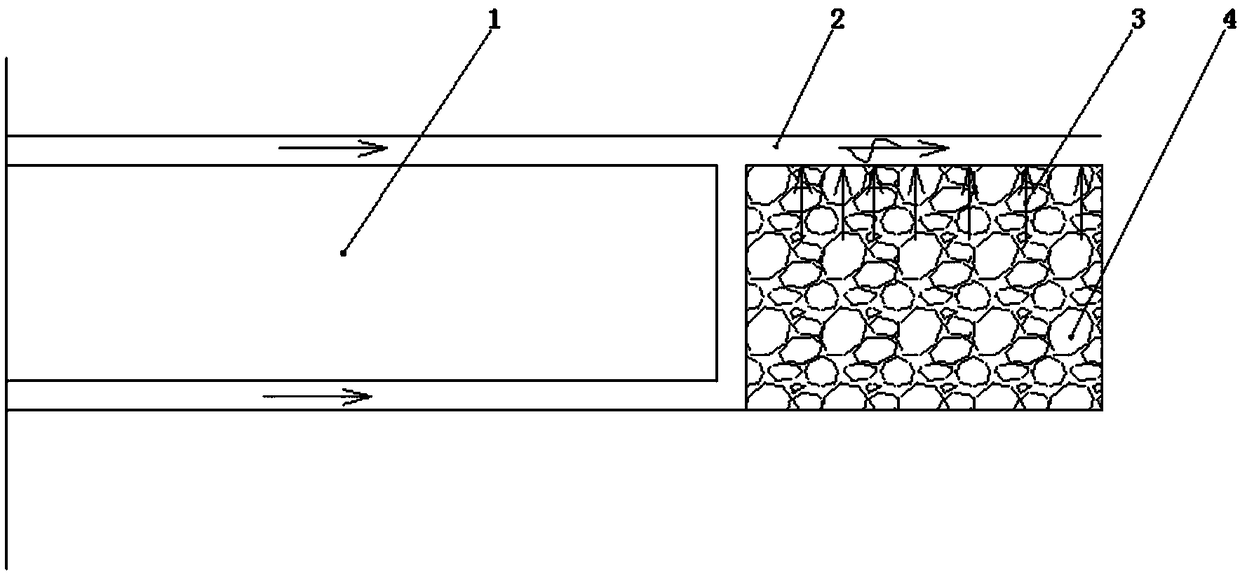

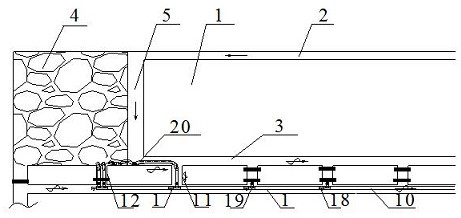

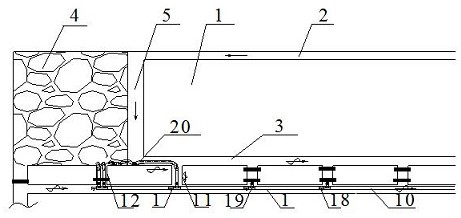

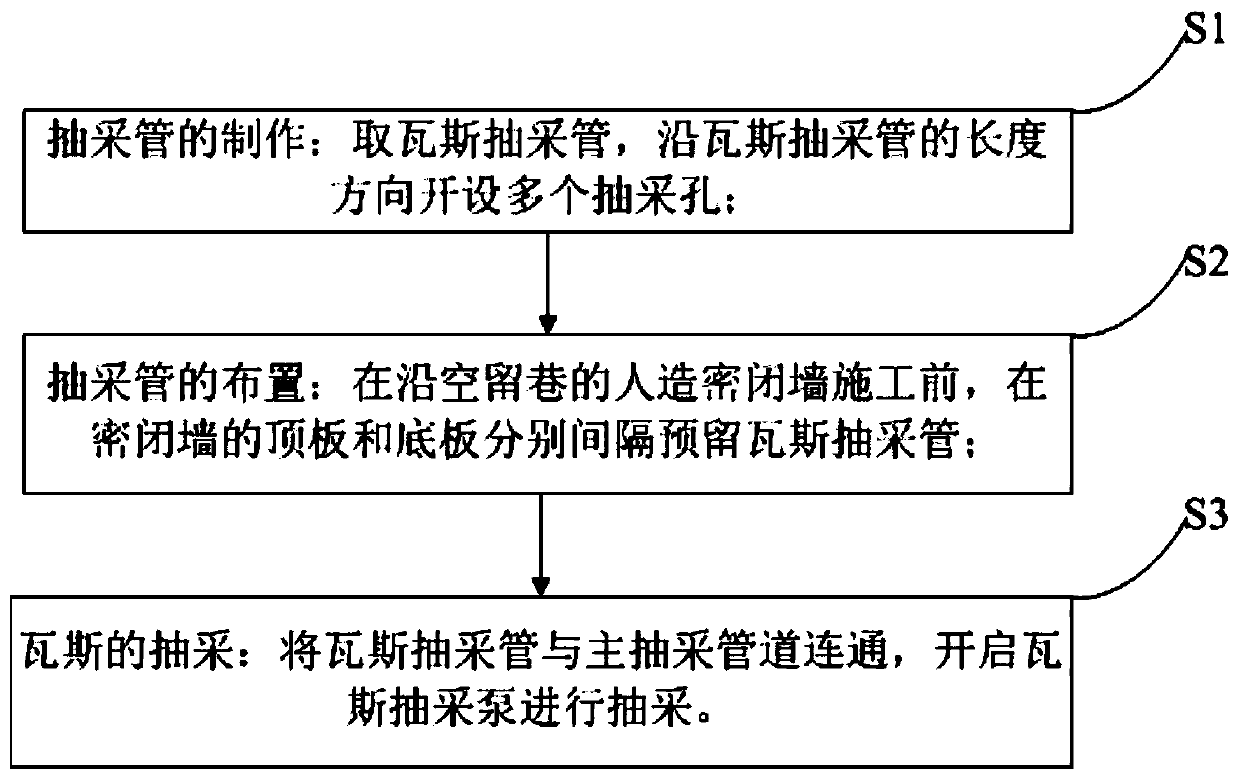

Surface type extraction method based on gob-side entry retaining gas treatment

The invention provides a surface type extraction method based on gob-side entry retaining gas treatment. The surface type extraction method mainly includes the steps that before a gob-side entry retaining artificial closed wall is constructed, gas extraction pipes are reserved on a top plate and a bottom plate of the closed wall at intervals, wherein the length of the extraction pipes is determined according to the length of an air leakage belt of a mine working face; gas is extracted, wherein the gas extraction pipes are communicated with a main extraction pipeline, a gas extraction pump is started for extraction. The method can effectively solve the return airway transfinite gas problem caused by gas released by residual coal, and the extraction effect is good. Construction is easy, andoperation construction can be carried out on the premise that normal ventilation of a return airway is not affected. Extraction holes in the gas extraction pipes are formed in the same side and are quick to drill. The extraction holes in the upper side and in the lower side are oppositely formed, that is, the extraction holes are formed face to face, and an extraction wall for surface type extraction is formed so that goaf gas carried by leaked air of the working face can be effectively intercepted, and the ventilation burden of the return airway is greatly relieved.

Owner:CCTEG SHENYANG RES INST

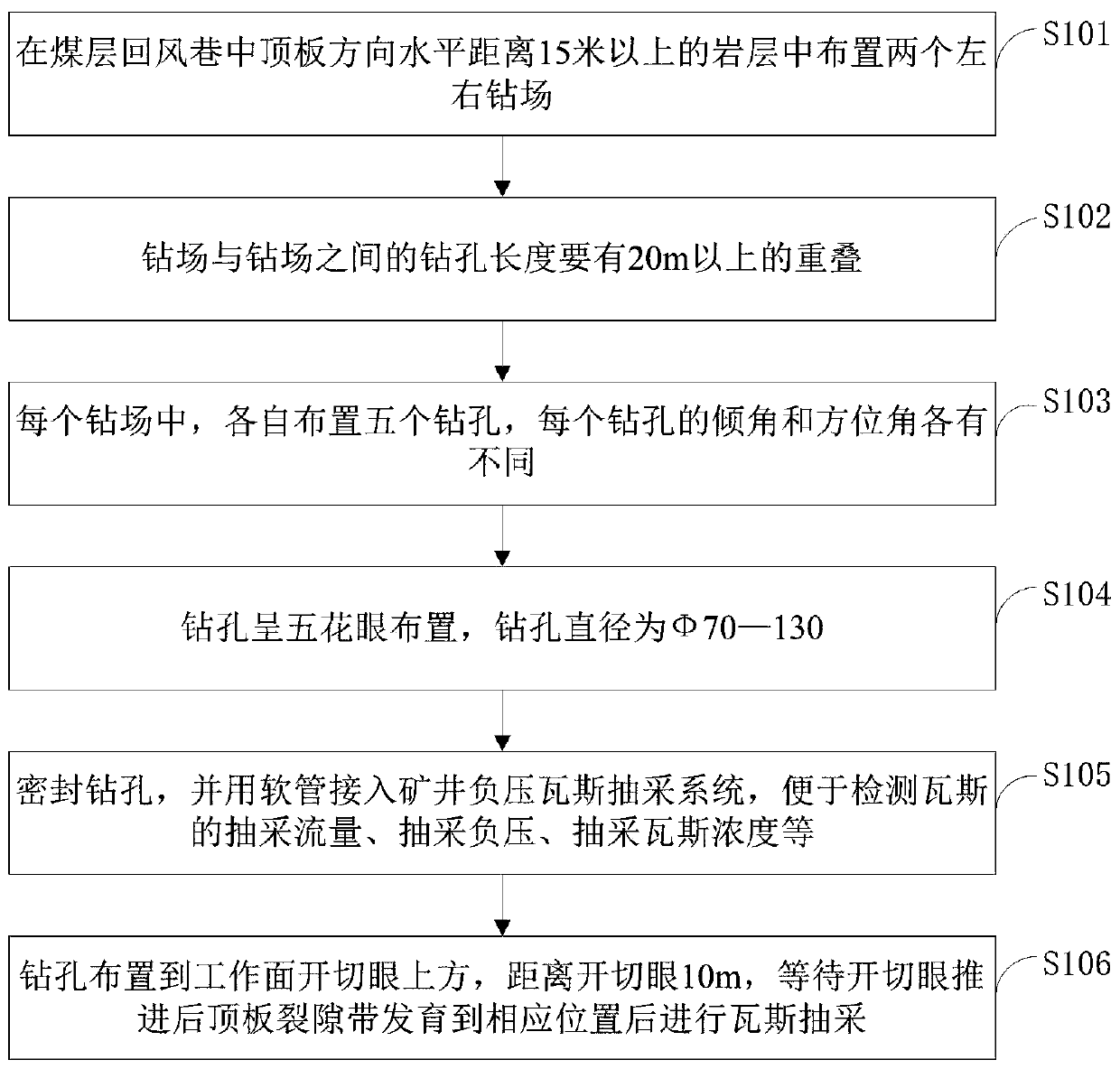

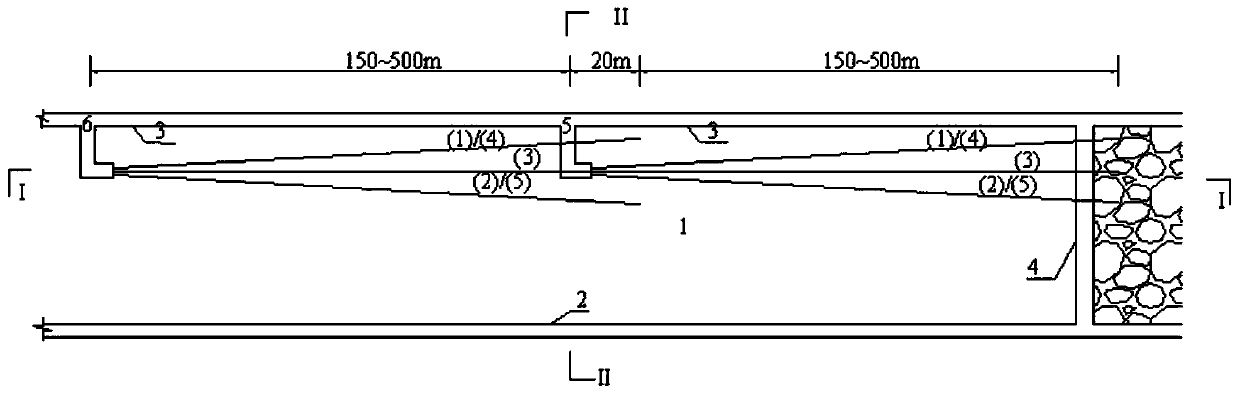

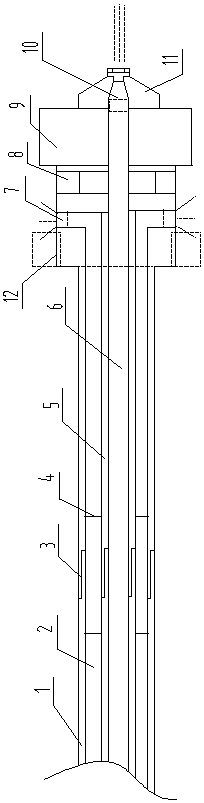

Gas extraction method during mining process and after mining of steep coal seam

InactiveCN109899037AImprove extraction efficiencySolve the overrun problemFluid removalGas removalCoal mine methaneGas concentration

The invention belongs to the technical field of coal mine gas extraction, and discloses a gas extraction method during the mining process and after mining of a steep coal seam. The gas extraction method comprises the steps that two left and right drill fields are arranged in rock strata with a horizontal distance of more than 15 meters in the roof direction in a coal seam return air way; the length of a borehole between the drill fields overlaps by more than 20m; five boreholes are formed in each drilling field correspondingly, and the inclination angle and azimuth angle of each borehole are different; the boreholes are arranged in a five-hole pattern, and the diameter of the drill holes is Phi 70-130; sealing drilling is carried out, a hose is used for being connected into a mine negativepressure gas extraction system to facilitate detection of gas extraction flow rate, extraction negative pressure, extraction gas concentration and the like; and the boreholes are formed above an opencut of a working face with 10m away from the open cut, and gas extraction is carried out after a roof fissure zone develops to the corresponding position after the open cut is pushed forwards. According to the gas extraction method, the drilling construction efficiency is high, the construction speed can be accelerated by more than 60%, the gas extraction concentration can reach more than 80%, and the gas extraction efficiency is improved.

Owner:HUNAN UNIV OF SCI & TECH

''U-and-U plus upper corner pump drainage'' stoping surface gas control method

ActiveCN111810221ASolve the overrun problemAvoid exception spewing problemsGas removalDrill holeCoal

The invention relates to a ''U-and-U plus upper corner pump drainage'' stoping surface gas control method. The method comprises the steps of U-and-U roadway arrangement, underground fixed extraction pump station system building and stoping surface normal bedding drilling, roof high-position drilling, and upper corner pump drainage arrangement. The manner of U-and-U roadway arrangement comprises two U-shaped ventilation system roadways; extraction is conducted through normal bedding drilling in a stoping surface air inlet roadway and a stoping surface air return roadway as well as roof high-position drilling in the stoping surface air return roadway; a backup surface air return roadway is used for stoping surface assisting air return; an embedded tube is arranged in a goaf and an extractionpipeline is arranged at an upper corner; and goaf embedded tube extraction and stoping surface upper corner extraction are realized. Compared with the prior art, the problem that large air amount isinduced into the stoping surface in case of multi-roadway ventilation so air leakage in mined-out areas is intensified and causes abnormal emission of gas is avoided, and the problems that in thick coal layer mined-out areas, excessive residual coal causes low stoping efficiency and stoping surface safety production is restricted by large emission of the gas in the mined-out areas are solved.

Owner:HENAN POLYTECHNIC UNIV

Goaf gas collection zone partition extraction method

InactiveCN110219694ASolve the overrun problemGuaranteed airtightGas removalHigh concentrationEngineering

The invention relates to a goaf gas collection zone partition extraction method. The technology used includes the following steps that an upper corner area of a fully-mechanized face is separated froma goaf through isolation walls; the isolation walls are built by regarding anchoring cables as frameworks and by waste materials such as underground gangue, and is sprayed with airtight spraying materials; as a working face advances, the isolation walls are arranged at intervals, and an air returning side gas collection zone in the goaf is divided into several isolation zones; in isolation areasfrom the working face into the goaf phase; nogs are arranged to assist and support top plates; extraction main pipes arranged in air returning lanes are divided into a plurality of extraction side pipes which are correspondingly connected into each partition, simultaneous extraction in the goaf air returning side deep portion and upper corner surrounding areas are achieved, and gas over-limit caused by a large amount of high concentration gas gathering in an upper corner is avoided; and when new isolation walls are set up and the extraction side pipes are can enter the goaf, a plurality of holes are correspondingly distributed on the extraction pipes, the extraction air inlet area is increased, and the extraction amount is increased.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

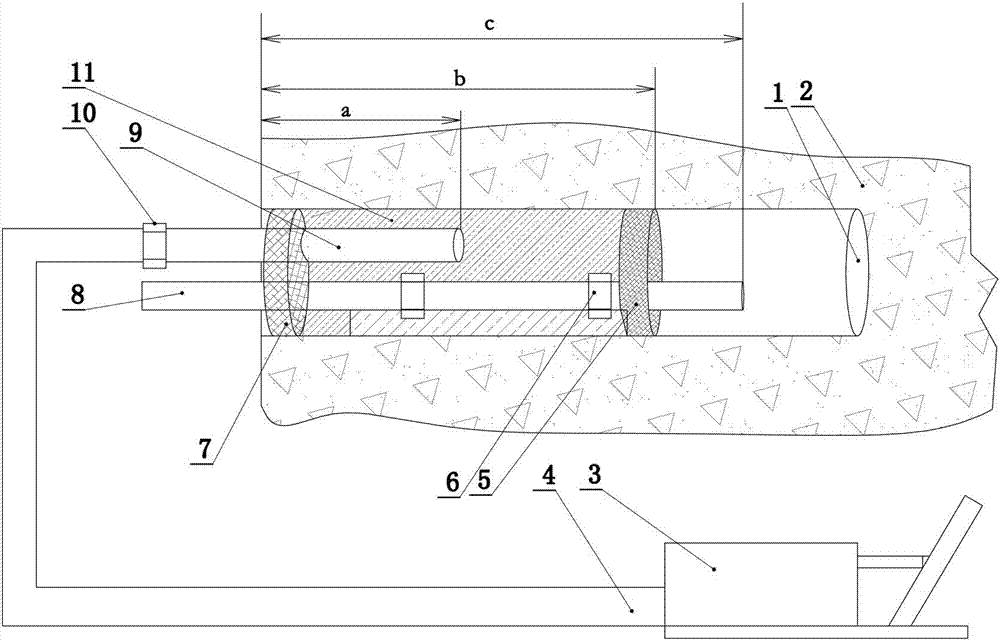

Ultra-high pressure long arm coal mass water injection hole sealing equipment and using method thereof

PendingCN107013182AReduce gas contentImprove working environmentSlitting machinesFluid removalDust explosionMechanical engineering

The invention discloses ultra-high pressure long arm coal mass water injection hole sealing equipment and a using method thereof. According to the ultra-high pressure long arm coal mass water injection hole sealing equipment and the using method thereof, a coal mass long arm water injection hole can be sealed rapidly, and water is injected into a coal mass. The hole sealing equipment comprises a grouting pump, a hole sealing material pressure-injection pipe and a hole sealing pipe. The depth of inserting of the hole sealing pipe into a water injection drilled hole is a. The grouting pump is connected with the hole sealing pipe through the hole sealing material pressure-injection pipe. The depth of inserting of a water injection pipeline into the water injection drilled hole is b, and b is larger than a. The tail end of the water injection pipeline is wrapped with an inner cotton plug. The parts, at a hole opening of the water injection drilled hole, of the hole sealing pipe and the water injection pipeline are wrapped with outer cotton plugs. A cavity between the outer cotton plugs and the inner cotton plug serves as a hole sealing cavity. By adopting the process method, the water enters into the coal mass to release part of gas, so that the gas content of the coal mass is decreased effectively; and after the effect of water injection is achieved, the amount of dust can be decreased by 80% or above, the operation environment of a worker is improved, a dust explosion accident is eradicated, the coal mass is moistened, the cost is reduced, and the security of the worker is increased.

Owner:枣庄矿业(集团)付村煤业有限公司

Flue gas displacement reinforced goaf gas extraction and goaf fire preventing and controlling method

ActiveCN109854294AReduce pressure differenceSolve the problem of air leakageGas removalSpontaneous combustionFlue gas

The invention relates to a flue gas displacement reinforced goaf gas extraction and goaf fire preventing and controlling method. The flue gas displacement reinforced goaf gas extraction and goaf firepreventing and controlling method is suitable for underground use of a coal mine, and comprises the steps that during the stoping process, a rock stratum above a goaf is broken and moved, an annular fracture zone is formed at the position of a caving arch, gas released in the stoping process is enriched, and gas injection pipelines are arranged on a roadside of the outer side of an air inlet lanein a paved mode and buried into the goaf; a drilling field is arranged at one side of an air return lane, pumping and extracting drilling holes are formed in from a drilling field to the caving arch position of the goaf, factory waste flue gas is injected into the goaf through the gas injection pipelines, and the gas enriched in the fracture zone is pumped and extracted through the pumping and extracting drilling holes; the flue gas is used for inhibiting the spontaneous combustion of residual coal in the goaf, the flue gas is injected into the goaf to balance the air pressure in the goaf by using belt pressure, and the air leakage of a working surface to the goaf is weakened; and flue gas is used for replacing, displacing and lifting the gas in the residual coal and surrounding rock to float to the fracture zone, and the gas pumping and extracting amount and the gas pumping and extracting concentration in the pumping and extracting drilling holes are improved to achieve the effects ofthe prevention and control of the fire in the goaf and improving the quality of the gas pumping and extracting.

Owner:CHINA UNIV OF MINING & TECH

Fully-mechanized caving mining process technology with large mining height in super-high seam (14-20m)

ActiveCN101967975BIncrease coal breaking effectIncrease coal discharge spaceUnderground miningSurface miningResource recoveryMineralogy

Owner:DATONG COAL MINE GRP

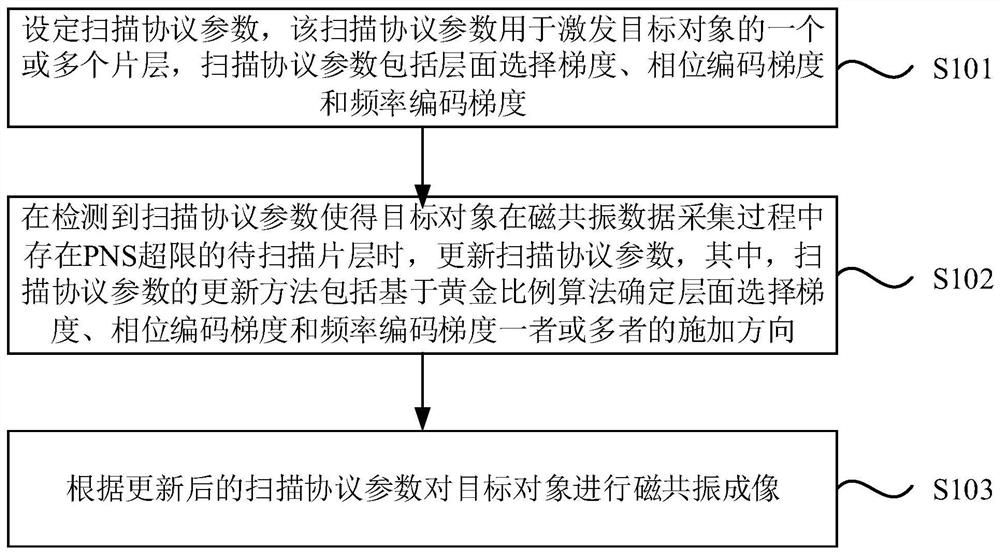

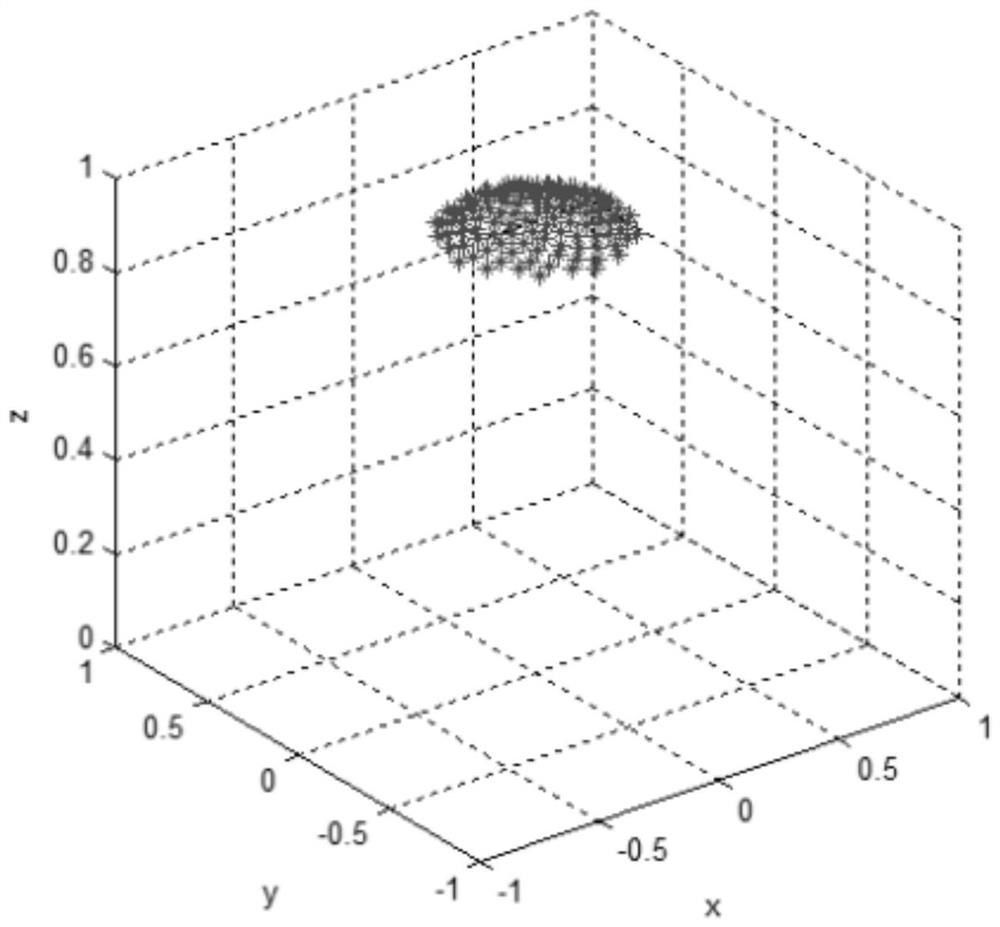

Scanning protocol parameter determination method and magnetic resonance system

PendingCN113759298AShort time spentReduce MRI timeMeasurements using magnetic resonanceWater resource assessmentNuclear physicsFrequency encoding

The embodiment of the invention discloses a scanning protocol parameter determination method and a magnetic resonance system, and the method comprises the steps: setting scanning protocol parameters which are used for exciting one or more slice layers of a target object, and comprise a layer selection gradient, a phase coding gradient and a frequency coding gradient; when it is detected that the scanning protocol parameters enable a target object to have a to-be-scanned slice layer with PNS ultralimit in the magnetic resonance data acquisition process, updating the scanning protocol parameters, the updating method of the scanning protocol parameters comprising the following steps: determining an application direction of one or more of a layer selection gradient, a phase coding gradient and a frequency coding gradient based on a golden proportion algorithm; and performing magnetic resonance imaging on the target object according to the updated scanning protocol parameters. The problem that time and labor are wasted when scanning protocol parameters are modified in a magnetic resonance scanning method in the prior art is solved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

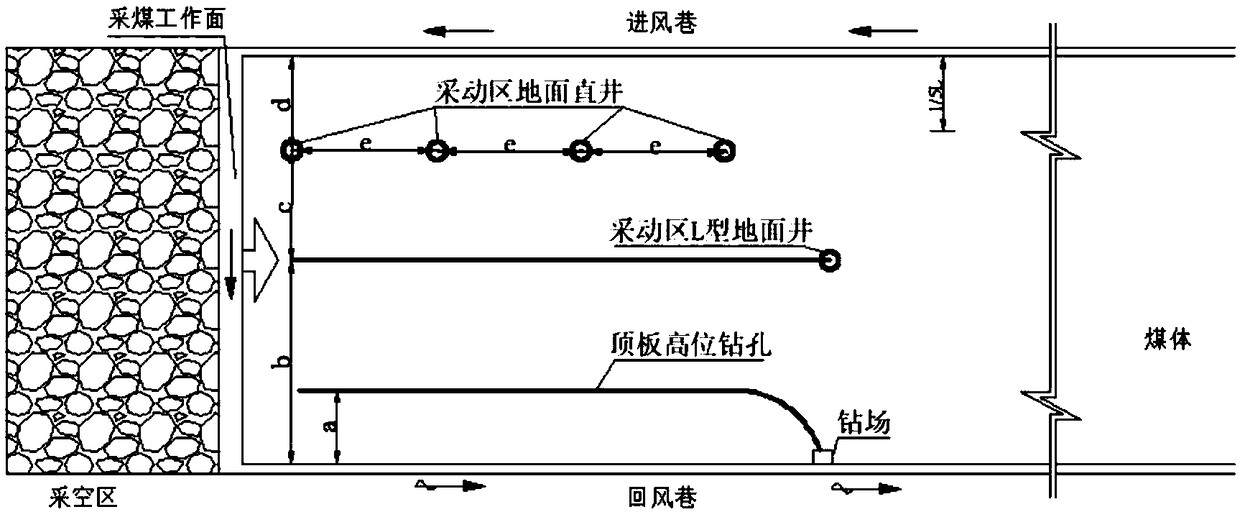

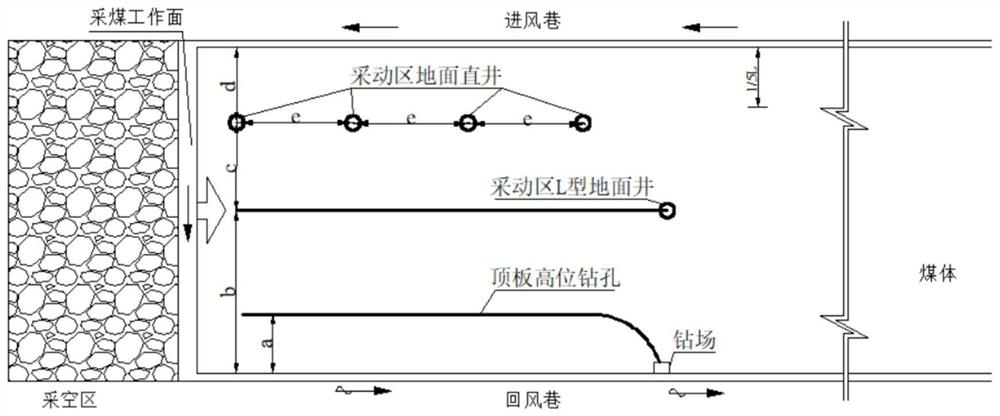

High gas coal mining working face gas improving method withtunnel replaced with well

ActiveCN109322697ASolve the overrun problemReduce construction costsGas removalBuilding constructionEnvironmental geology

The invention discloses a high gas coal mining working face gas improving method with a tunnel replaced with a well. The high gas coal mining working face gas improving method adopts the following steps that Step1, space positions of a mining area ground well vertical well, a mining area L-shaped ground well and a high position drilling hole are optimized and arranged; Step 2, instant gas extraction quantity of the mining area ground well vertical well, the mining area L-shaped ground well and the high position drilling hole is calculated correspondingly, and gas quantity q that can be desorbed instantly after extracting; Step 3, gas quantity q' instantly pouring out from the coal mining working face is calculated; and Step 4, whether a measure replacing the tunnel with the well achieves the purpose that improves coal mining working face gas over limits and remedying measure and improves the high gas coal mining working face gas with the well replacing the tunnel or not are assessed. According to the high gas coal mining working face gas improving method with the tunnel replaced with the well, the over limit problems of the coal mining working face, an upper corner and an air return tunnel can be solved, extracting with the measurewith the tunnel replaced with the well achieves the requirement of coal mining working face improving, and meanwhile, the construction cost is greatly reduced.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Method for extracting top coal gas during fully-mechanized top coal caving period of extra-thick coal seam

PendingCN113653527ASolve the overrun problemReduce influxMining devicesDirectional drillingMining engineeringCoal mine methane

The invention relates to the technical field of coal mine gas extraction, and discloses a method for extracting top coal gas during a fully-mechanized top coal caving period of an extra-thick coal seam. The method comprises the following steps of (1) designing bedding directional long drilling parameters: designing the bedding directional long drilling parameters according to coal seam occurrence conditions and firmness coefficients; (2) conducting directional drilling construction, specifically, conducting bedding directional long drilling on the coal seam before working face stoping, connecting a pipeline to a hole opening, and the pipeline is connected with negative pressure extraction equipment; (3) crushing the top coal: repeatedly supporting and extruding the top coal by a bracket of a stope face to generate cracks in the coal seam, and continuously desorbing the gas in the coal seam; and (4) conducting top coal caving: during the top coal caving period, a large amount of gas rushes to the top of the working face and is continuously pumped out through a drill hole. The method solves the problem that a large amount of desorbable gas generated in the coal caving period cannot be effectively extracted in time through a coal seam roof high-position drilling hole or a high drainage roadway, the desorbable gas instantly flows into the working face, so that the gas of an upper corner or a return airway exceeds the limit.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A method of controlling gas in high-gas coal mining face by using well instead of roadway

ActiveCN109322697BSolve the overrun problemReduce construction costsGas removalMining engineeringPetroleum engineering

The invention discloses a method for controlling gas in a high-gas coal mining face by substituting a well for a roadway. The following steps are adopted: Step 1. Optimizing the layout of the space of the vertical well, the L-shaped ground well and the high-level drilling in the mining area location; Step 2, respectively calculate the instantaneous gas extraction volume of vertical wells in the mining area, L-shaped surface wells in the mining area, and high-level drilling holes, and obtain the instantaneous desorbable gas volume q after extraction; Step 3: Calculate the amount of coal mining work Instantaneous desorbable gas quantity q´; Step 4: Evaluate whether the measures of "replacing roadways with wells" have reached the limit and remedial measures to control high-gas coal mining face gas purpose. By adopting the method of the invention, the gas overrun problem of the coal mining face, the upper corner, and the air return roadway can be solved, and the method of "replacing the roadway with a well" is adopted for drainage to meet the requirements of controlling the gas in the coal mining face, and at the same time, the construction cost is greatly reduced .

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

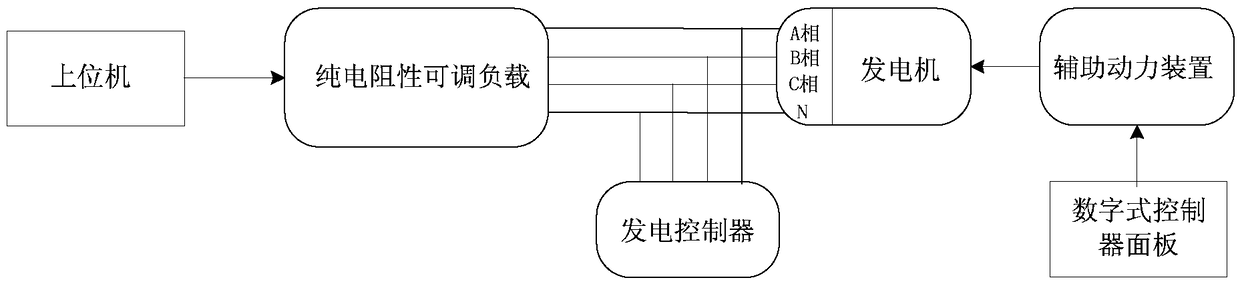

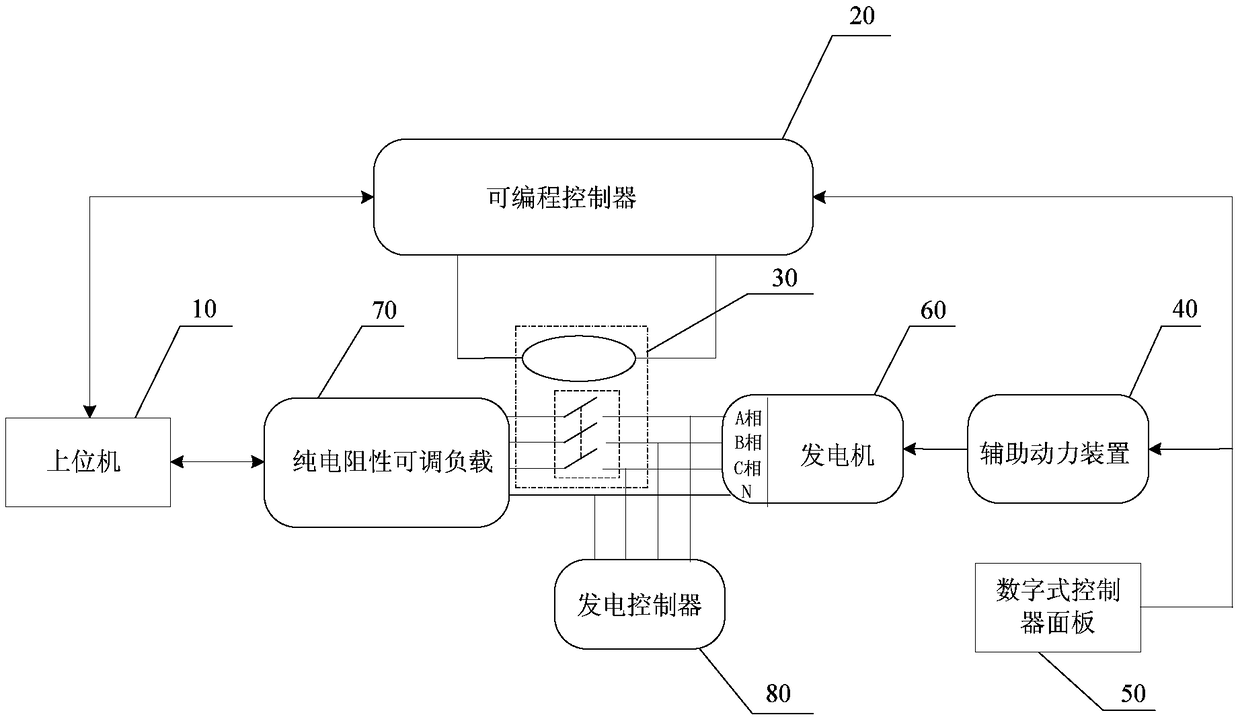

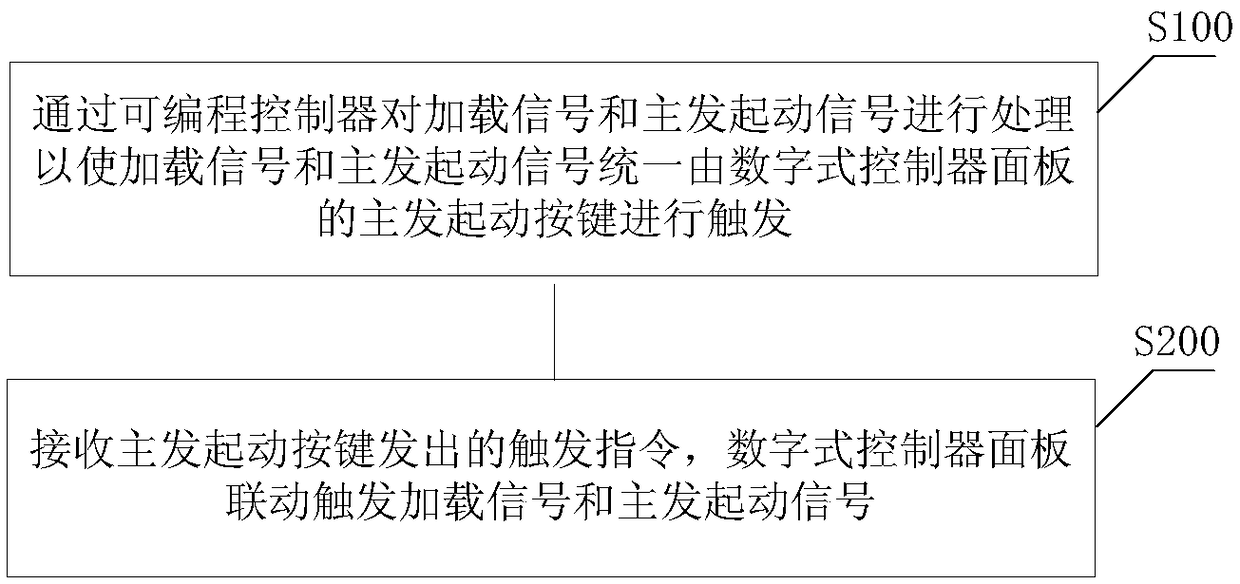

Main engine linkage test system and method

The invention discloses a main initiated linkage test system and method. The system is composed of an upper computer, a programmable controller, a contactor, an auxiliary power unit, a digital controller panel, a generator, a purely resistive adjustable load and a generation controller. The generator, the purely resistive adjustable load, and the contactor are connected in series successively to form an electrical loop. Main initiated starting signals on the digital controller panel are divided into two paths; at one path, the programmable controller controls the coil of the contactor to open or close so as to realize connection or disconnection of the electrical loop; and at the other path, a fuel adjusting value of the auxiliary power unit is connected to adjust the fuel amount. Besides, a main initiated starting key is arranged on the digital controller panel; and the programmable controller is used for processing a loading signal and a main initiated starting signal, so that the loading signal and the main initiated signal are triggered together in a linkage manner by the main initiated starting key, so that an excess revolution problem during the main initiated starting process can be solved. The main initiated linkage test system has advantages of fast response speed, high automation degree, and high reliability.

Owner:CHINA AVIATION POWER MACHINE INST

Method for pumping out gas from mining coal layer roof

Owner:HUAINAN MINING IND GRP +1

A "u and u + upper corner pumping" gas control method in the mining face

ActiveCN111810221BSolve the overrun problemAvoid exception spewing problemsGas removalThermodynamicsAir volume

The invention relates to a method for controlling gas in the mining face of "U and U + upper corner pumping and drainage", including "U and U" roadway layout, underground fixed drainage pumping station system construction, normal bedding drilling of the mining face, and high-level roof Arrangement of drilling and upper corner extraction. The "U and U" roadway layout includes two U-shaped ventilation system roadways, through the common bedding drilling of the inlet airway and the return airway of the mining face, and the high-level drilling of the roof of the return airway of the mining face for drainage. The wind tunnel is used as an auxiliary air return at the mining surface, and the goaf buried pipe and the upper corner extraction pipeline are arranged to realize the buried pipe drainage of the goaf and the upper corner extraction of the mining surface. Compared with the existing technology, it avoids the problem of abnormal gas gushing caused by the aggravation of air leakage in the goaf when the large air volume is introduced into the mining face during multi-lane ventilation, and solves the recovery rate caused by excessive coal falling in the goaf of thick coal seams Low and large gas emission in the goaf restricts the safety production of the mining face.

Owner:HENAN POLYTECHNIC UNIV

A Surface Drainage Method Based on Gas Control in Gob-side Entry

ActiveCN109236354BReduce ventilation burdenEnsure safe productionGas removalForming faceSurface type

The invention provides a surface type extraction method based on gob-side entry retaining gas treatment. The surface type extraction method mainly includes the steps that before a gob-side entry retaining artificial closed wall is constructed, gas extraction pipes are reserved on a top plate and a bottom plate of the closed wall at intervals, wherein the length of the extraction pipes is determined according to the length of an air leakage belt of a mine working face; gas is extracted, wherein the gas extraction pipes are communicated with a main extraction pipeline, a gas extraction pump is started for extraction. The method can effectively solve the return airway transfinite gas problem caused by gas released by residual coal, and the extraction effect is good. Construction is easy, andoperation construction can be carried out on the premise that normal ventilation of a return airway is not affected. Extraction holes in the gas extraction pipes are formed in the same side and are quick to drill. The extraction holes in the upper side and in the lower side are oppositely formed, that is, the extraction holes are formed face to face, and an extraction wall for surface type extraction is formed so that goaf gas carried by leaked air of the working face can be effectively intercepted, and the ventilation burden of the return airway is greatly relieved.

Owner:CCTEG SHENYANG RES INST

Totally-closed blowout prevention and dust falling device

PendingCN114151033AAvoid high dust concentrationsSolve gas overrunConstructionsDrilling accessoriesDrill holeEngineering

The invention provides a totally-closed blowout prevention dust falling device which is characterized in that a transverse dust baffle is arranged in a blowout prevention box body, the dust baffle is installed on the inner wall of a dust prevention box body, and a backflow opening is formed between the dust baffle and the inner wall of the dust prevention box body; an air inlet and an air outlet are formed in a top plate of the blowout prevention box body, and the air outlet is located above the dust baffle; the air inlet pipe is inserted into the blowout prevention box body from the air inlet and penetrates through the backflow port; the air outlet pipe is installed on the air outlet. According to the invention, the hole spraying prevention and dust removal effects in the drilling construction process are improved, the working environment is improved, and the safety is guaranteed.

Owner:河南省正龙煤业有限公司

Method for extracting gas in adjacent sections through non-coal-pillar gob-side entry retaining

PendingCN113217080AReduce construction difficultyReduce construction costsGas removalMining engineeringStructural engineering

The invention provides a method for extracting gas in adjacent sections through non-coal-pillar gob-side entry retaining, relates to the technical field of gas extraction, and aims to solve the problem that the existing coal-pillar-free mining method cannot effectively reduce gas overrun of a driving face. The method for extracting the gas in the adjacent sections through the non-coal-pillar gob-side entry retaining comprises the following steps that first bedding drill holes are formed in the gob-side entry retaining of a stope face and a first mining face transportation roadway in the inclined direction of a coal seam, and the tail ends of the first bedding drill holes are located at the position of a connecting face track roadway of the adjacent sections; and in the tunneling process of the connecting face track roadway tunneling working faces of the adjacent sections, second bedding drill holes are formed in the connecting face track roadway tunneling working faces in the coal seam trend, so that the second bedding drill holes and the first bedding drill holes form a latticed three-dimensional intersection state, and the second bedding drill holes communicate with the first bedding drill holes at least through cracks. By means of the method for extracting the gas in the adjacent sections through the non-coal-pillar gob-side entry retaining, gas overrun of the driving face can be effectively avoided.

Owner:华能煤炭技术研究有限公司

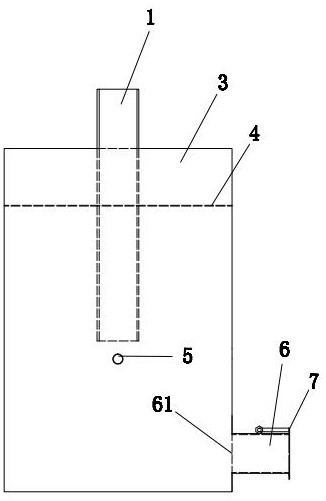

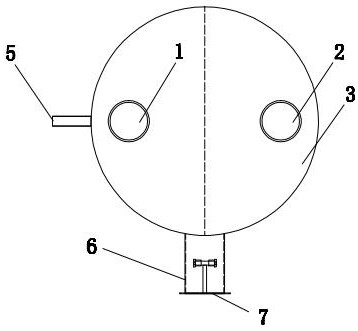

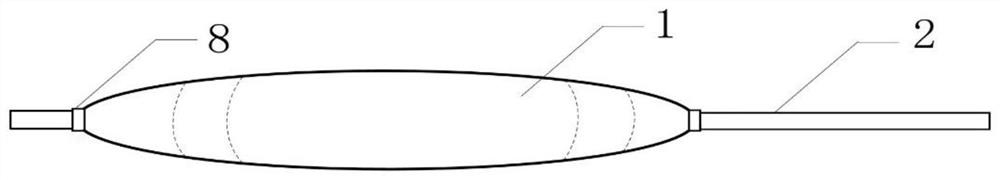

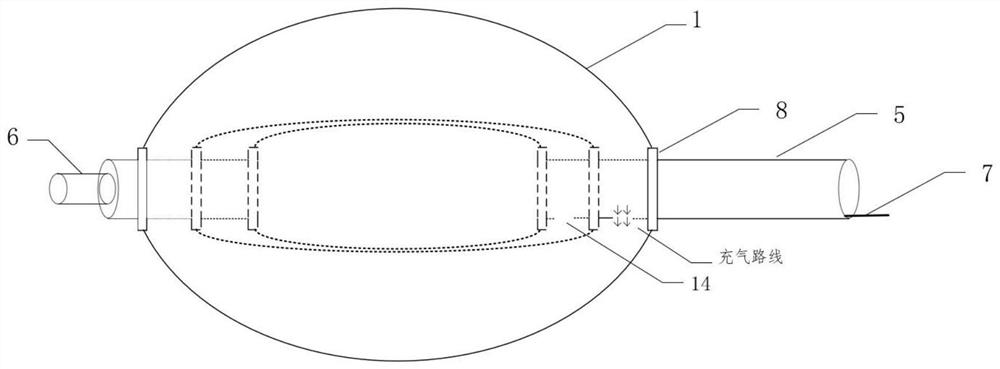

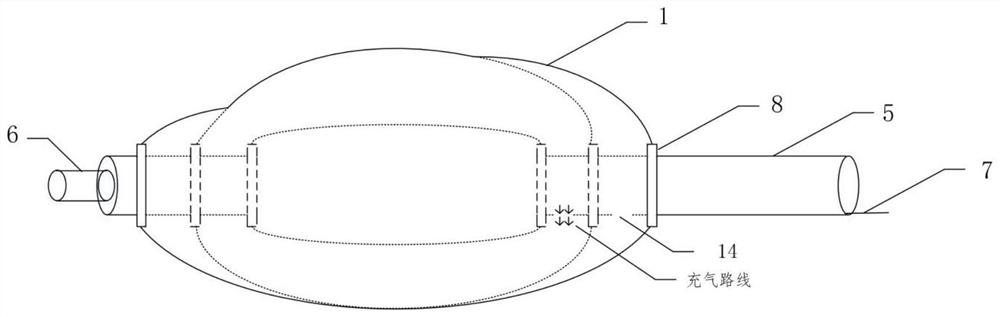

A multi-functional integrated inflatable air bag device for gas plugging, drainage and pressure relief in goaf

ActiveCN112832847BSolve the overrun problemReduce damage rateMining devicesMaterial fill-upCollection systemStructural engineering

The invention relates to a multifunctional integrated inflatable air bag device for gas plugging, extraction and pressure relief in a goaf, including an air bag plugging system, a catheter drainage system, an air bag inflation and pressurization system, and a gas extraction and gas collection system; the air bag plugging system Surrounding the outside of the catheter drainage system, it is connected to the catheter drainage system through a ferrule; the end of the catheter drainage system far away from the goaf, that is, the tail, is connected to the air bag inflation and pressurization system through an external leather tube; the gas collection system is located at the end of the catheter drainage system The front of the port, that is, the front of the tail, is connected from the side by an external leather tube. The invention makes the upper corner gas treatment more effective, stable and precise, and effectively solves the problems of buried pipe, suspended pipe drainage pipe Louis damage, low air tightness of drilling drainage, and gas accumulation in the upper corner of the mining working face, and solves the problems of To a certain extent, it solves the problem of air leakage in the goaf, and provides good technical support and safety measures for the safe and efficient mining of coal resources.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A Safe and Clean Ventilation System Applicable to the Mining Face of the Roof Cutting and Pressure Relief 110 Method

ActiveCN109083674BHarm reductionReduce disaster accidentsTunnel/mines ventillationWorking environmentEngineering

The invention discloses a safe and clean ventilating system suitable for a top cutting pressure relief construction method 110 mining working face. The safe and clean ventilating system comprises a mining area air return downhill roadway and a mining area belt downhill roadway, the right wing recovery working face is arranged on the right side of the mining area belt downhill roadway, a right boundary track downhill roadway is arranged on a mining area right boundary position, a mine is provided with a track main roadway, a belt main roadway and a total air return way, the mining area belt downhill roadway is communicated with the belt main roadway, the right boundary track downhill roadway is communicated with the track main roadway, and the mining area air return downhill roadway is communicated with the total air return way; the right wing recovery working face comprises a recovery-completed working face, an in-mining working face and a to-be-mined working face, when mining of the in-mining working face is performed, the mining area belt downhill roadway is sequentially communicated with a first air inlet roadway of the in-mining working face, the recovery working face, an air return roadway and the mining area air return downhill roadway, and the right boundary track downhill roadway is communicated with a second air inlet roadway. The safe and clean ventilating system canreduce air leakage of a gob region, improve the working environment and eliminate corner gas accumulation.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

Permeability enhancement method for ultra-thin layer water jet mining in low permeability soft coal seam

InactiveCN104727795BMining engineering cycle is longLow costFluid removalGas removalSlagRelease time

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com