Coal mine gas extraction method

A coal mine gas and drainage technology, which is applied in gas emission, mining equipment, mining equipment, etc., can solve the problems of unstable negative pressure, complex and changeable, and large difference in negative pressure of gas drainage, so as to reduce emissions and ensure the essence safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

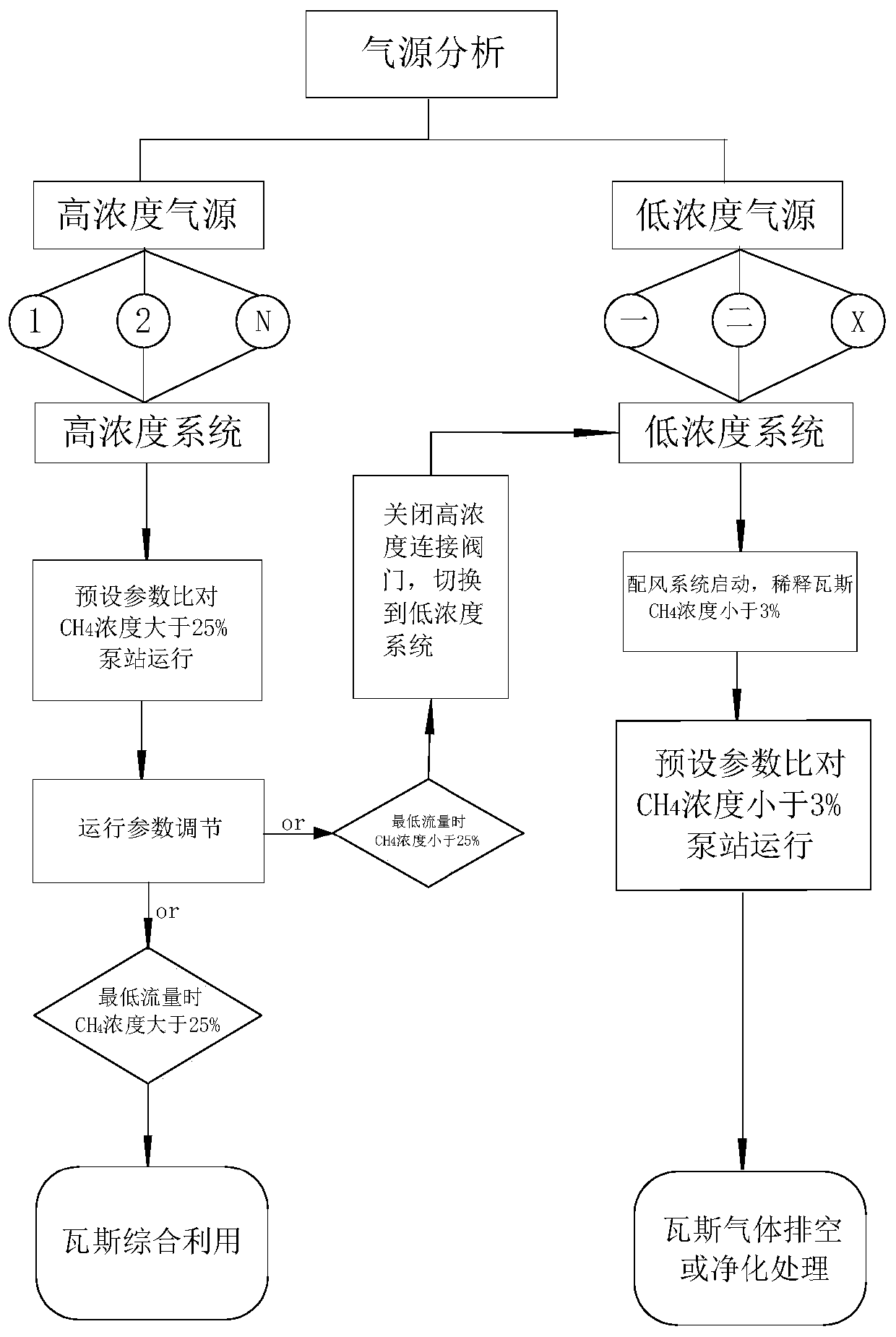

[0021] Such as image 3 Shown, the coal mine gas extraction method of the present invention comprises the steps:

[0022] Analyze the gas source and divide the gas source into high-concentration gas source and low-concentration gas source, the gas concentration in the high-concentration gas source is ≥25%, and the gas concentration in the low-concentration gas source is <25%,

[0023] Use the high-concentration extraction system to carry out extraction operations on high-concentration gas sources, comprehensively utilize the extracted high-concentration gas, and detect the gas concentration of high-concentration gas sources in real time through the automatic detection and control system. When the gas concentration is less than 25% When using the automatic detection control system, adjust the drainage parameters of the high-concentration drainage system to increase the gas concentration. When the gas concentration cannot be increased to ≥ 25%, the high-concentration gas source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com