Fully mechanized caving face gob-side entry retaining process and ventilating method

A fully-mechanized caving face and ventilation method technology, which is applied in mine/tunnel ventilation, gas discharge, earthwork drilling and mining, etc., can solve the problems of high support strength and gas exceeding the limit, so as to improve the strength and reduce the pressure , the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

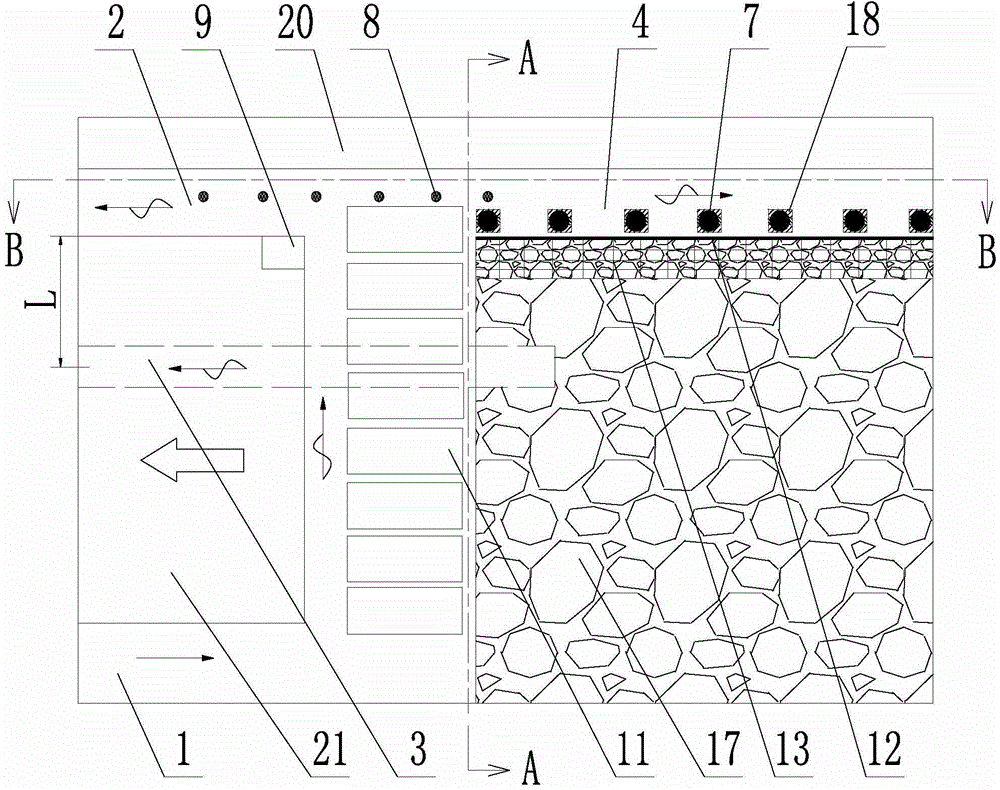

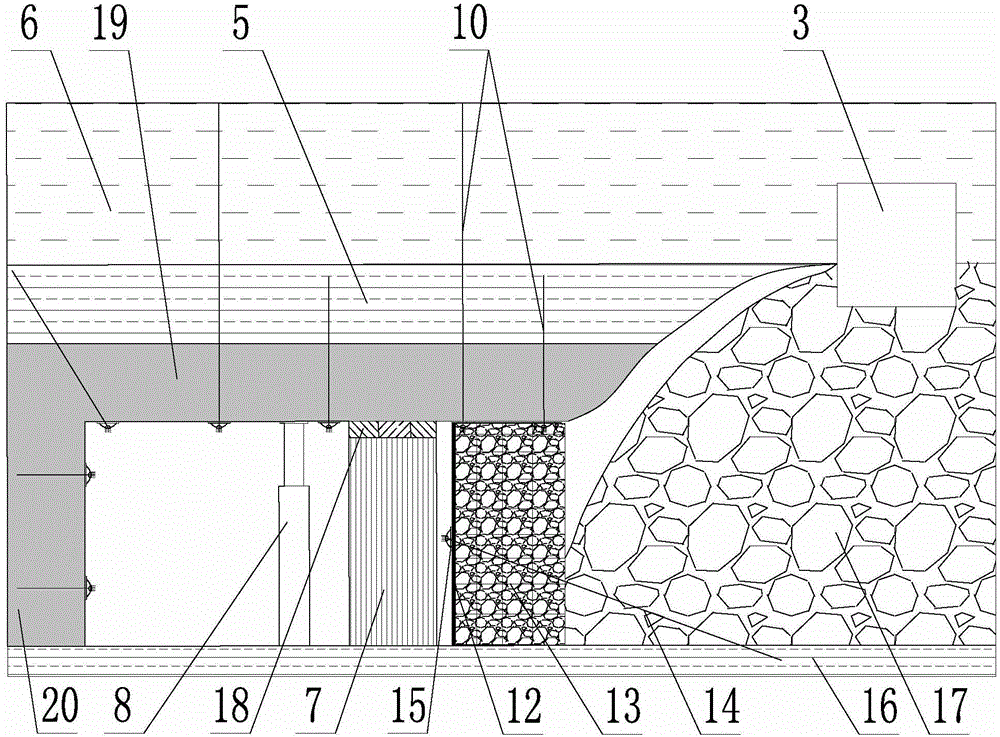

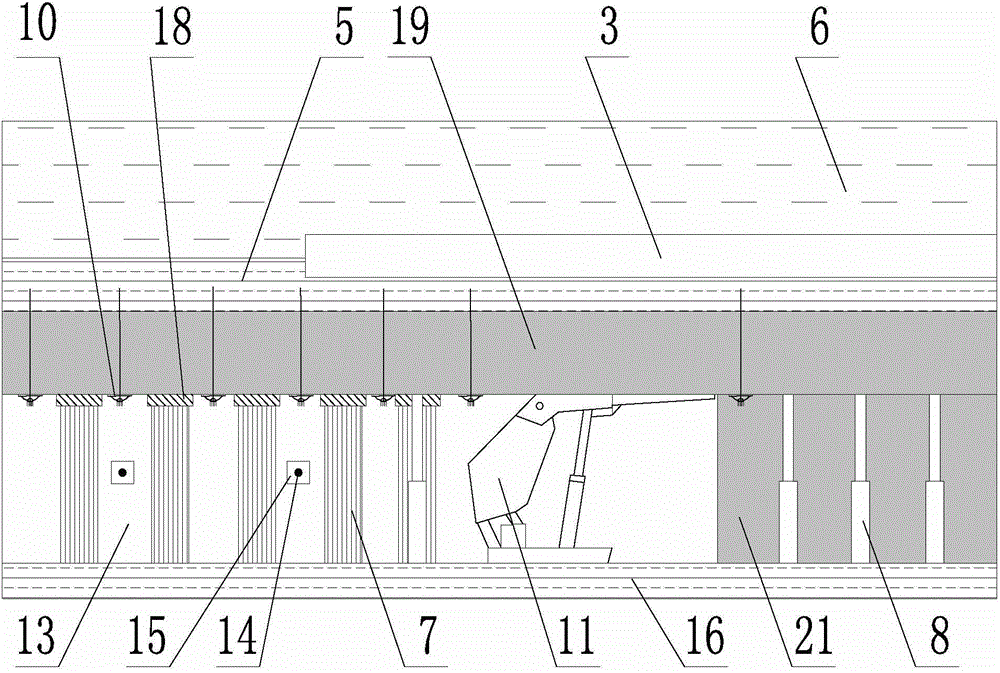

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] A process and ventilation method for gob-side entry retention in a fully mechanized caving face, comprising the following steps:

[0036] Step 1: Arrange an air inlet lane 1 on one side of the fully mechanized caving face, and arrange a return air lane 2 on the other side of the fully mechanized caving face;

[0037] Step 2: Arrange a gas discharge lane 3 in the direct roof 5 or the basic roof 6, and the gas discharge lane 3 is arranged in parallel with the return air lane 2;

[0038] Step 3: Reserving the air return lane 2 behind the fully mechanized caving face as gob-side lane retention 4, and carry out the gob-side lane retention operation;

[0039] Step 4: When the gob-side retention operation is completed, the fresh air flows from the air inlet lane 1 into the working face to dilute the gas on the working face, and part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com