Totally-closed blowout prevention and dust falling device

A dust suppression device and fully enclosed technology, applied in safety devices, gas discharge, drilling equipment, etc., can solve problems such as gas overrun accidents, high dust concentration, and restrictions on the health of workers in safe production, so as to avoid high dust concentration and solve problems The effect of gas overrun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

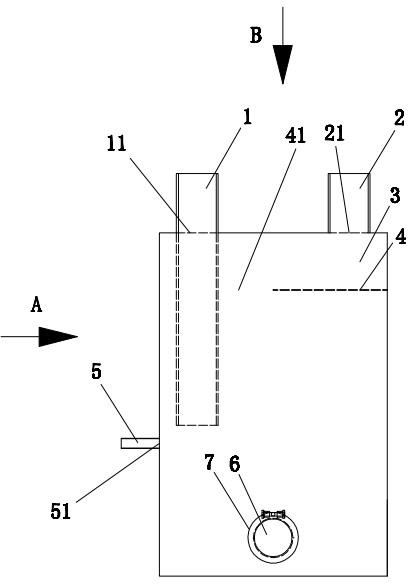

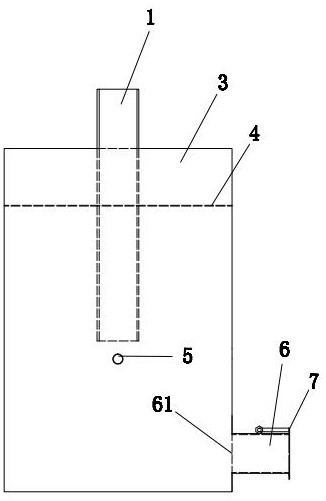

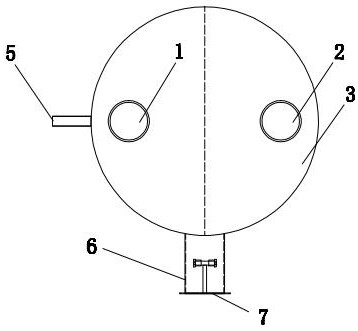

[0019] In order to illustrate the technical solution of the present invention more clearly, the accompanying drawings that need to be used in the description will be briefly introduced below. Obviously, the accompanying drawings in the following description are only some embodiments of the present invention. As far as people are concerned, other embodiments can also be obtained according to these drawings on the premise of not paying creative work. In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 , figure 2 , image 3 Shown:

[0021] The present invention comprises a blowout-proof box body 3, and the upper part of the blowout-proof box body 3 is provided with a horizontal dust-shielding plate 4, and the dust-shielding plate 4 is installed on the inner wall of the dust-proof box body 3, and its area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com