Mine dust concentration and environmental parameter automatic detection and control system

A technology of dust concentration and environmental parameters, which is applied in the direction of dust prevention, mining equipment, mining equipment, etc., can solve the problems that the system does not consider environmental factors, is not suitable for the actual site, and is expensive, so as to avoid excessive dust concentration and reduce explosion Possibility, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

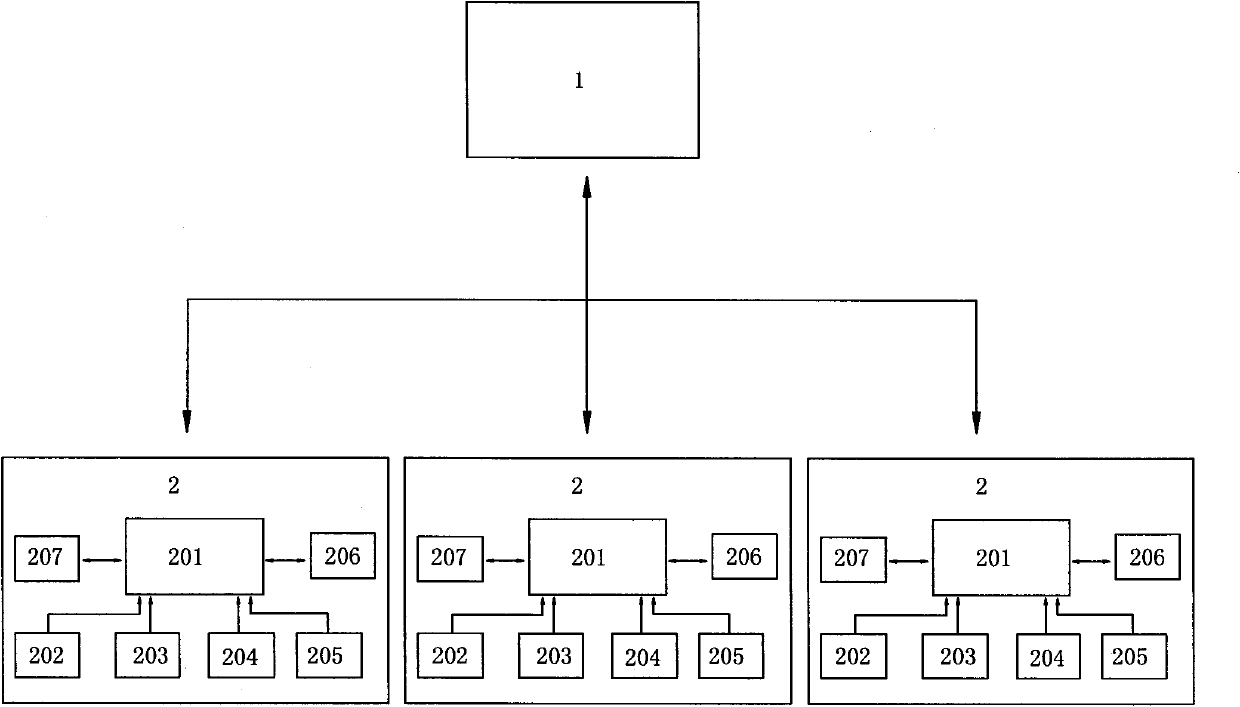

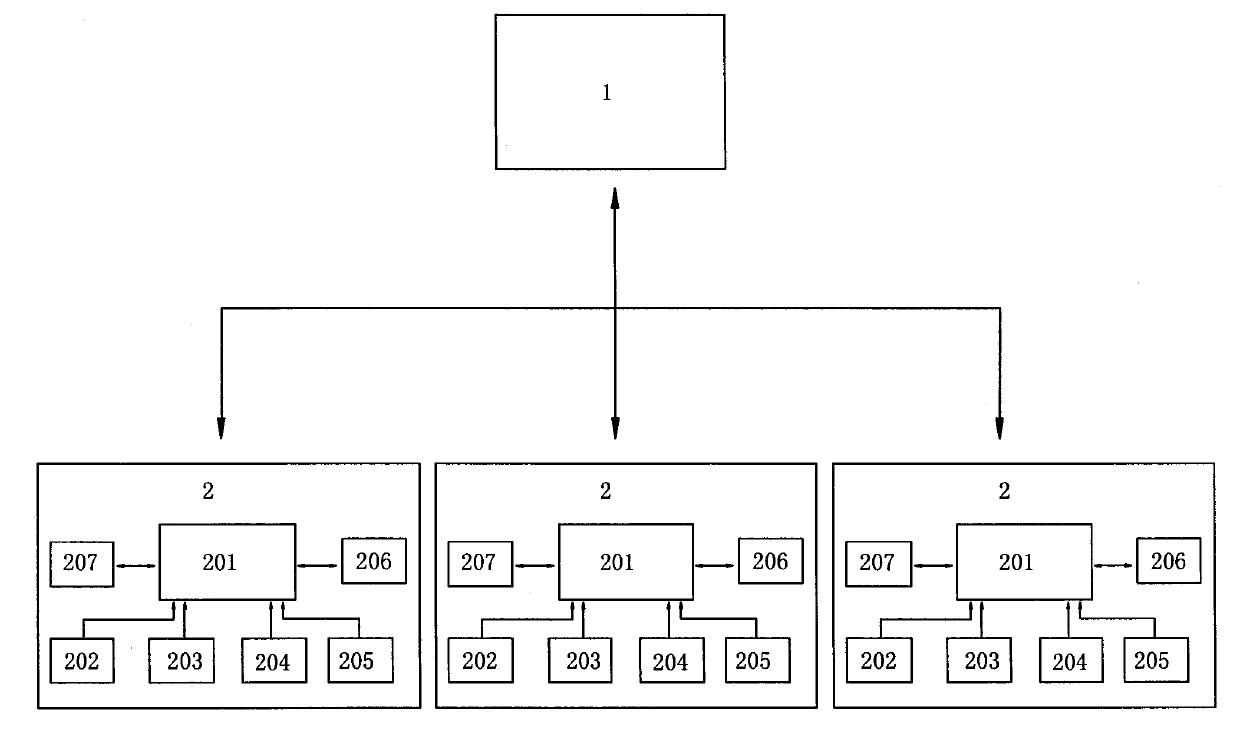

[0018] Referring to the accompanying drawings, an automatic detection and control system for mine dust concentration and environmental parameters includes an upper computer 1 located on the well and at least one downhole control unit 2 . The number of downhole control units 2 can be freely configured according to different conditions of downhole operation areas (points), and the arrangement area where one downhole control unit is located can be used as a measurement area (point). This example shows three downhole control units. Take a downhole control unit as an example below to illustrate it: it includes a downhole sensor group, a downhole PLC controller 201 and downhole external equipment; the downhole sensor group includes a dust concentration sensor 202, a temperature and humidity sensor 203, a flow sensor 204 and an infrared sensor The sensor 205, wherein the dust concentration sensor 202 is used to measure the dust concentration of the environment, can be installed above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com