Ultra-high pressure long arm coal mass water injection hole sealing equipment and using method thereof

An ultra-high pressure, water injection hole technology, applied in mining equipment, mining fluids, earthwork drilling, etc., can solve the problems of easy rupture of connecting parts, increase operating costs, damage to pluggers, etc., to improve the working environment of workers, increase A sense of security, the effect of preventing outstanding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

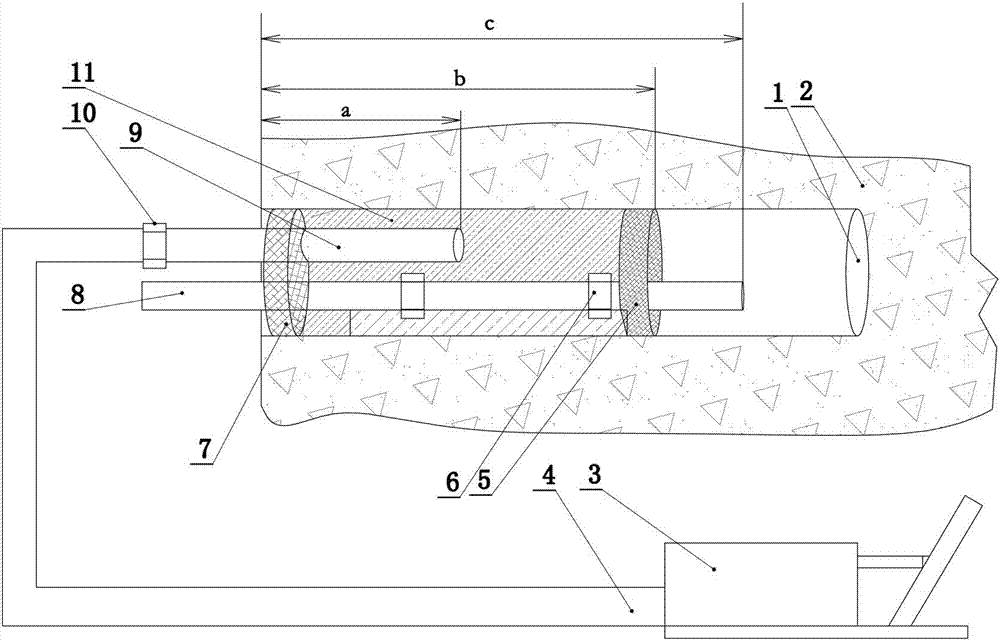

[0025] The UHV long-arm coal water injection hole sealing equipment includes a grouting pump, a sealing material injection pipe, and a sealing pipe. Hole pipe connection, the water injection pipeline is inserted into the water injection drilling depth b, b is greater than a.

[0026] The end of the water injection pipeline is wrapped with an inner cotton plug, and the sealing tube at the position of the water injection drilling hole and the water injection pipeline are wrapped with an outer cotton plug. The cavity between the outer cotton plug and the inner cotton plug is a sealing cavity for Provide enough plugging space for Marysan to plug the water injection borehole. Preferably, the outer tampon and the inner tampon are cotton yarns wound around the outer wall of the tube, and iron wires are bound around the tampon.

[0027] As a preference, the outer tampon and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com