High gas coal mining working face gas improving method withtunnel replaced with well

A technology for coal mining face and gas, which is applied in the fields of gas discharge, mining equipment, earth-moving drilling, etc., can solve the problems of gas explosion, gas concentration exceeding the limit, affecting the safe production of coal mining face, etc., and achieves the goal of reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

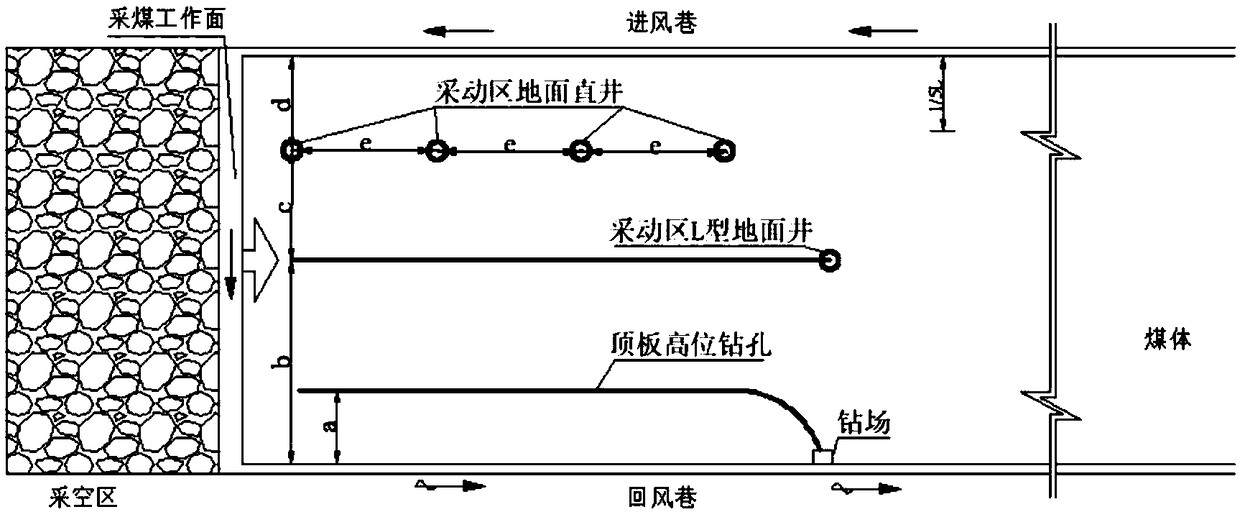

[0044] figure 1 It is a schematic diagram of the layout of vertical wells in the mining area, L-shaped surface wells in the mining area, and high-level drilling. A method for controlling gas in a high-gas coal mining face by substituting a well for a roadway, the following steps are adopted:

[0045] Step 1. Optimizing the layout of the spatial positions of vertical wells in the mining area, L-shaped surface wells in the mining area, and high-level drill holes;

[0046] Step 2. Calculate the instantaneous gas extraction volume of vertical surface wells in the mining area, L-shaped surface wells in the mining area, and high-level boreholes respectively, and obtain the instantaneous desorbable gas amount q after extraction;

[0047] Step 3, calculating the gas quantity q′ instantaneously gushing out from the coal mining face;

[0048] Step 4. Compare q' with q. When qq', increase the number of vertical wells in the mining area to control coal mining For the gas in the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com